Hazardous industrial environments demand robust communication tools to ensure worker safety and operational continuity. An IP Explosion Proof Telephone provides an essential lifeline in such high-risk settings, offering unmatched reliability under extreme conditions. Industries like oil and gas, which recorded over 734,000 job-related injuries recently, rely on these devices to mitigate risks. Similarly, the American Chemistry Council highlighted an $864 billion chemical production output in 2022, underscoring the need for secure communication systems in chemical manufacturing. Moreover, global mining operations, producing over 16 billion metric tons annually, emphasize the importance of tools like the ATEX Explosion Proof Telephone for effective communication. Solutions such as the IP67 waterproof telephone and offshore weatherproof telephone further enhance safety and efficiency in challenging environments.

Enhancing Safety in Hazardous Industrial Environments

Compliance with international explosion-proof standards

Industries operating in hazardous environments must adhere to strict safety regulations to protect workers and equipment. IP Explosion Proof Telephones comply with globally recognized standards, ensuring their reliability in high-risk areas. Certifications such as IECEx, ATEX, and NEC validate these devices for use in explosive atmospheres. For instance, the IECEx standard is widely accepted across Europe, Australia, and the USA, while ATEX facilitates trade within the European Union by defining safety requirements for explosive environments. In North America, the National Electrical Code (NEC) includes standards like UL913, which governs explosion-proof equipment. These certifications provide industries with the confidence to deploy IP Explosion Proof Telephones in compliance with international safety protocols.

| Standard | Description |

|---|---|

| IECEx | Recognized globally for explosion-proof equipment, including Europe and USA. |

| ATEX | European directive for safety systems in explosive environments. |

| NEC | North American standard for explosion-proof equipment, including UL913. |

| CNEX | Chinese certification for electrical products in hazardous areas. |

| CSA | Canadian safety standards for explosion-proof equipment. |

Durability and resistance to extreme conditions

IP Explosion Proof Telephones are engineered to withstand the harshest industrial conditions. Their robust construction ensures durability in environments with extreme temperatures, high humidity, and corrosive substances. For example, the weather-resistant TAD01 telephone features an IP66 certification, a GRP handset, and a stainless steel armored cord, making it suitable for hazardous areas. Similarly, the ATEX-certified JREX106 telephone incorporates corrosion-resistant hardware and a noise-canceling microphone, ensuring clear communication even in noisy industrial settings. These features make IP Explosion Proof Telephones indispensable for industries like oil and gas, chemical manufacturing, and mining, where environmental challenges are constant.

| Feature | Description |

|---|---|

| Type | Weather-resistant telephone (TAD01) |

| Certification | IP66 for hazardous areas |

| Material | GRP handset with stainless steel armored handset cord |

| Type | ATEX telephone (JREX106) |

| Certification | Certified for hazardous areas |

| Features | Corrosion-resistant hardware, noise-canceling microphone |

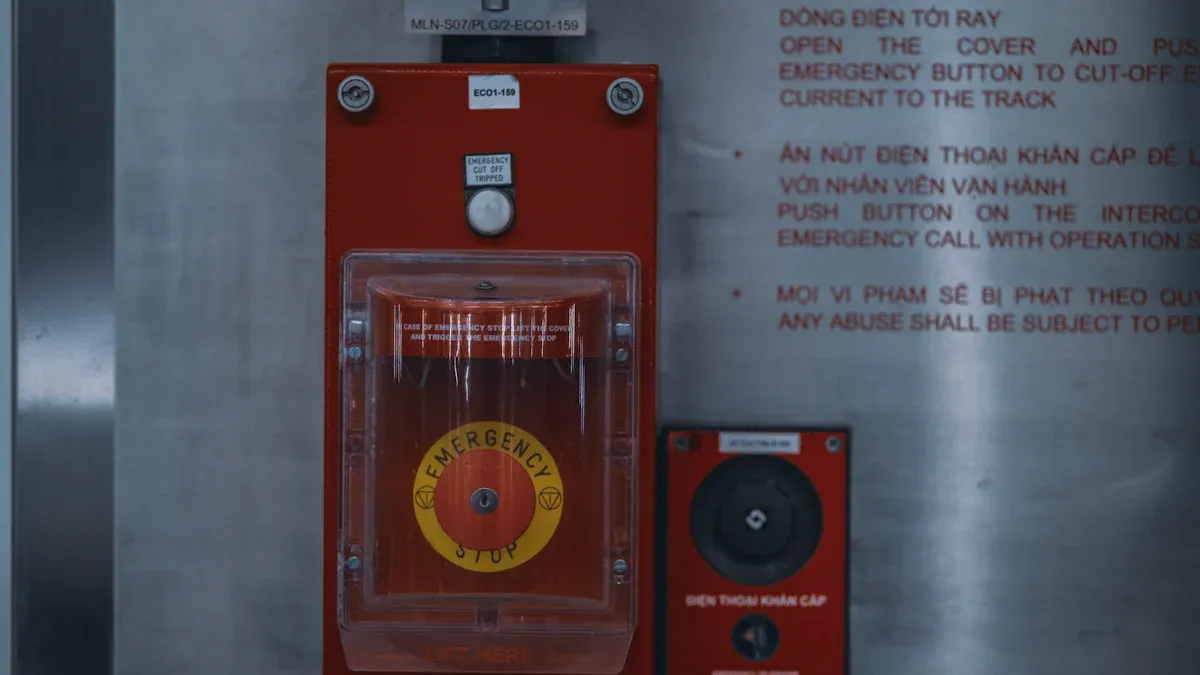

Emergency communication capabilities

In emergencies, reliable communication can save lives. IP Explosion Proof Telephones provide critical connectivity in hazardous environments, enabling workers to report incidents or request assistance instantly. Devices like the ATEX industrial telephone (T4FP-15333) are designed for wall mounting and certified for hazardous environments with IP66 protection. Additionally, the analog industrial telephone (JREX106-A03) features an explosion-proof aluminum alloy body, ensuring functionality during emergencies. These telephones are vital for industries where rapid response times can prevent accidents and minimize damage.

| Feature | Description |

|---|---|

| Type | ATEX industrial telephone (T4FP-15333) |

| Certification | Certified for hazardous environments with IP66 protection |

| Type | Wall mounting type |

| Type | Analog industrial telephone (JREX106-A03) |

| Certification | Designed for emergency use in hazardous areas |

| Material | Explosion-proof and weatherproof aluminum alloy die-casting body |

Boosting Operational Efficiency with IP Explosion Proof Telephones

IoT integration for real-time monitoring and control

Industries increasingly rely on IoT-enabled devices to enhance operational workflows. IP Explosion Proof Telephones equipped with IoT capabilities allow real-time monitoring and control in hazardous environments. These devices transmit critical data, such as temperature, pressure, and equipment status, to centralized systems, enabling swift decision-making.

IoT integration has revolutionized industrial processes by improving safety and productivity. Approximately 50% of mines adopted IoT in 2023, showcasing the growing trend toward automation. Predictive maintenance, implemented by 19% of mines for mobile equipment and 23% for plants, further highlights the operational benefits of IoT-enabled telecommunication systems.

Key advancements in IoT technology have also driven market growth for explosion-proof communication devices. These devices operate safely in high-risk environments, ensuring uninterrupted communication and enhancing overall efficiency.

5G-enabled communication for faster data transmission

The integration of 5G technology into IP Explosion Proof Telephones has transformed industrial communication. 5G operates on high-frequency bands between 24 GHz and 100 GHz, delivering faster data transmission speeds compared to 4G. This improvement reduces latency and enhances connectivity, enabling seamless communication in hazardous environments.

- Carrier aggregation and 256-QAM technologies optimize data efficiency, ensuring reliable performance even in challenging conditions.

- Industries benefit from 5G-enabled telecommunication systems, which facilitate real-time data sharing and improve operational workflows.

The adoption of 5G technology in explosion-proof telecommunication systems supports industries in meeting stringent safety and efficiency requirements. Enhanced connectivity ensures that workers and equipment remain synchronized, minimizing downtime and maximizing productivity.

User-friendly interfaces for streamlined operations

Modern IP Explosion Proof Telephones feature user-friendly interfaces designed for ease of use in demanding industrial settings. These interfaces simplify communication processes, allowing workers to focus on their tasks without unnecessary distractions.

Devices with intuitive controls and clear displays reduce training time and improve operational efficiency. Advanced features, such as touchscreens and programmable buttons, enable customization to meet specific industrial needs.

Technological advancements have also introduced enhanced audio quality and wireless connectivity, further streamlining operations. These improvements align with industry demands for safety compliance and operational efficiency, as evidenced by significant market growth in explosion-proof telecommunication systems.

| Evidence Type | Details |

|---|---|

| Market Growth | Significant growth in the industrial explosion-proof telephone market due to demand in hazardous environments. |

| Safety Compliance | Increased focus on safety and operational efficiency driven by stringent regulatory requirements. |

| Technological Advancements | New features such as enhanced audio quality and wireless connectivity improve operational workflows. |

User-friendly designs ensure that IP Explosion Proof Telephones remain indispensable tools for industries seeking to optimize their operations while maintaining safety standards.

Emerging Trends in IP Explosion Proof Telephones

Wearable technology for hands-free communication

Wearable technology is transforming industrial communication by enabling hands-free operation in hazardous environments. Devices such as headsets and smart glasses equipped with explosion-proof features allow workers to stay connected without compromising safety. These wearables integrate seamlessly with IP Explosion Proof Telephones, offering real-time communication and data sharing. For instance, workers in mining or oil and gas sectors can use voice-activated commands to report incidents or access critical information, reducing the need for manual handling. This innovation enhances productivity while ensuring compliance with safety standards.

The adoption of wearable technology reflects a growing trend toward automation and worker-centric solutions in high-risk industries.

Advanced certifications for diverse industrial applications

The demand for explosion-proof telecommunication devices has driven the development of advanced certifications. These certifications ensure that devices meet the unique safety requirements of various industries. For example, certifications like IECEx and ATEX validate the use of IP Explosion Proof Telephones in explosive atmospheres, while UL913 and CSA standards cater to North American markets. This focus on compliance with stringent international safety standards has expanded the adoption of these devices across sectors such as construction, chemical manufacturing, and mining.

- The market for IP explosion-proof telephones is projected to grow at a CAGR of 7.38% from 2024 to 2032.

- By 2032, the market size is expected to reach USD 10.6 billion, driven by industries like oil and gas.

Cost-efficient designs with enhanced functionality

Manufacturers are prioritizing affordability to make explosion-proof telecommunication devices accessible to a broader audience. Cost-efficient designs now incorporate advanced features such as IoT integration, 5G connectivity, and enhanced durability. These innovations improve functionality without significantly increasing costs. The focus on affordability aligns with market trends emphasizing ruggedness and advanced communication capabilities.

Enhanced durability and affordability are key factors driving the adoption of explosion-proof telecommunication systems in high-risk industries.

Addressing Challenges in Explosion-Proof Telecommunication

Managing high costs of development and deployment

The development and deployment of explosion-proof telecommunication systems require significant financial investment. High capital expenditure for infrastructure development poses a major challenge for manufacturers and service providers. The telecom industry, for instance, invests approximately 15 cents of capital for every dollar of revenue, creating financial strain and limiting opportunities for smaller companies. Additionally, economic downturns can exacerbate these challenges. Consumers often reduce services during such periods, impacting the profitability of telecom investments.

| Challenge | Description |

|---|---|

| High capital expenditure for infrastructure | Telecom companies face high capital intensity, averaging 15 cents of investment per dollar earned. |

| Financial sustainability concerns | Reduced pricing power and inflation force companies to streamline operations and innovate. |

| Impact of economic downturns | Economic challenges lead to reduced consumer spending, affecting telecom profitability. |

To address these issues, companies must adopt cost-efficient designs and explore partnerships to share financial burdens. Streamlining operations and leveraging automation can also help reduce expenses.

Simplifying certification processes

Obtaining certifications for explosion-proof devices involves complex and time-consuming procedures. Each certification, such as ATEX or IECEx, requires rigorous testing to meet international safety standards. This process often delays product launches and increases costs. Simplifying these procedures through unified global standards could accelerate certification timelines. Collaborative efforts between regulatory bodies and manufacturers can also reduce redundancies, ensuring faster market entry for compliant devices.

Innovative solutions to overcome industry barriers

Innovation plays a crucial role in overcoming barriers in explosion-proof telecommunication. Manufacturers are exploring advanced materials and technologies to enhance device durability while reducing costs. IoT integration and modular designs allow for easier upgrades, minimizing the need for complete system overhauls. By focusing on research and development, companies can create solutions that address industry-specific challenges while maintaining safety and efficiency.

IP Explosion Proof Telephones significantly enhance safety and operational efficiency in hazardous industries. Their ability to withstand explosive atmospheres ensures reliable emergency communication, while GPS and IoT integration streamline operations. With rising market demand driven by safety regulations and advanced technologies, these devices are essential for meeting future industrial safety standards.

| Evidence Type | Description |

|---|---|

| Safety Enhancement | Explosion-proof telephones are designed to withstand explosive atmospheres, ensuring reliable communication critical for emergency responses. |

| Operational Efficiency | Integration of GPS and IoT technologies enables real-time monitoring and data sharing, enhancing operational efficiency. |

| Market Demand | The market is driven by safety regulations and technological advancements, with a focus on workplace safety standards in hazardous environments. |

| Consumer Preferences | Consumers are willing to pay more for explosion-proof features, indicating a strong market demand for safety and advanced functionalities. |

FAQ

What industries benefit the most from IP Explosion Proof Telephones?

Industries like oil and gas, chemical manufacturing, and mining rely heavily on these devices for safety and operational efficiency in hazardous environments.

How do IP Explosion Proof Telephones ensure durability?

These devices feature robust materials like stainless steel and corrosion-resistant hardware, making them resistant to extreme temperatures, humidity, and corrosive substances.

Tip: Always check for certifications like ATEX or IECEx to ensure the device meets your industry’s safety standards.

Are these telephones compatible with modern technologies like IoT and 5G?

Yes, many models integrate IoT and 5G technologies, enabling real-time monitoring, faster data transmission, and seamless communication in high-risk industrial settings.