CVD SIC Coating is a highly durable protective layer developed through the chemical vapor deposition process. This SIC Coating provides exceptional protection for semiconductor equipment, safeguarding it from wear and corrosive environments. Manufacturing challenges, such as equipment degradation and contamination, can be effectively addressed with CVD Coating. By enhancing durability, it ensures reliable performance and minimizes downtime, which is essential for high-precision operations.

Key Takeaways

- CVD SiC Coating gives strong protection to semiconductor tools. It makes them last longer and wear out less.

- This coating helps tools handle heat and chemicals better. It lets them work well in tough conditions.

- Using CVD SiC Coating makes your tools last longer. This lowers repair costs and boosts how much work they can do.

Understanding CVD SIC Coating

The Chemical Vapor Deposition (CVD) Process

The Chemical Vapor Deposition (CVD) process is a method used to create thin, high-quality coatings on various surfaces. In this process, you expose a substrate to a mixture of gases at high temperatures. These gases react chemically, forming a solid material that deposits onto the surface. This technique allows for precise control over the coating’s thickness and uniformity.

CVD is particularly effective for producing silicon carbide (SiC) coatings. The process ensures that the coating adheres strongly to the substrate, providing a durable and protective layer. By using CVD, you can achieve coatings that are free of defects and capable of withstanding extreme conditions.

Key Properties of Silicon Carbide (SiC)

Silicon carbide (SiC) is a material known for its exceptional properties. It is incredibly hard, ranking just below diamond on the Mohs scale. This hardness makes it resistant to wear and abrasion. SiC also has excellent thermal conductivity, which helps it handle high temperatures without breaking down.

Another key property of SiC is its chemical stability. It resists corrosion from acids, alkalis, and other harsh chemicals. This makes it ideal for environments where exposure to reactive substances is common. Additionally, SiC is lightweight yet strong, making it a versatile choice for various applications.

Why CVD SiC Coating Matters for Semiconductor OEMs

CVD SiC Coating plays a crucial role in the semiconductor industry. As a semiconductor OEM, you face challenges like equipment wear, contamination, and exposure to harsh chemicals. CVD SiC Coating addresses these issues by providing a protective barrier that enhances the durability of your equipment.

This coating also improves the performance of semiconductor tools. Its thermal stability ensures that equipment can operate at high temperatures without failure. The chemical resistance of SiC prevents damage from corrosive substances, reducing the risk of contamination. By using CVD SiC Coating, you can extend the lifespan of your equipment and maintain the precision required for semiconductor manufacturing.

Benefits of CVD SIC Coating

Superior Durability and Corrosion Resistance

You need equipment that can withstand the harsh conditions of semiconductor manufacturing. CVD SIC Coating offers unmatched durability, protecting surfaces from wear and abrasion. Silicon carbide’s hardness ensures that your tools resist physical damage, even during demanding operations.

Corrosion resistance is another critical benefit. When your equipment comes into contact with reactive chemicals, unprotected surfaces can degrade quickly. CVD SIC Coating acts as a shield, preventing corrosion and maintaining the integrity of your tools. This protection reduces the frequency of repairs and replacements, saving you time and resources.

Tip: Regularly inspect coated surfaces to ensure they remain free of defects. This practice helps you maximize the coating’s protective benefits.

Exceptional Thermal and Chemical Stability

Semiconductor manufacturing often involves extreme temperatures and exposure to aggressive chemicals. CVD SIC Coating excels in these conditions. Its thermal stability allows your equipment to operate at high temperatures without losing performance.

Chemical stability is equally important. Silicon carbide resists damage from acids, alkalis, and other corrosive substances. This property ensures that your tools remain functional and contamination-free, even in challenging environments. By using CVD SIC Coating, you can maintain consistent manufacturing quality and avoid costly disruptions.

Extended Equipment Lifespan

When you invest in high-precision equipment, you want it to last. CVD SIC Coating significantly extends the lifespan of your tools. Its protective layer minimizes wear and tear, reducing the risk of premature failure.

Longer equipment life means fewer replacements and lower overall costs. You can allocate resources to other areas of your operation, improving efficiency and productivity. With CVD SIC Coating, you get more value from your investment while maintaining optimal performance.

Cost Efficiency in High-Precision Manufacturing

Precision manufacturing demands reliable tools, but frequent repairs and replacements can strain your budget. CVD SIC Coating offers a cost-effective solution. By enhancing durability and stability, it reduces maintenance expenses and downtime.

You also benefit from improved operational efficiency. Coated equipment performs consistently, allowing you to meet production targets without delays. Over time, the savings from reduced maintenance and increased productivity outweigh the initial investment in CVD SIC Coating.

Note: Partnering with a trusted coating provider ensures you receive high-quality coatings that deliver maximum value.

Applications of CVD SIC Coating

Semiconductor Processing Equipment Protection

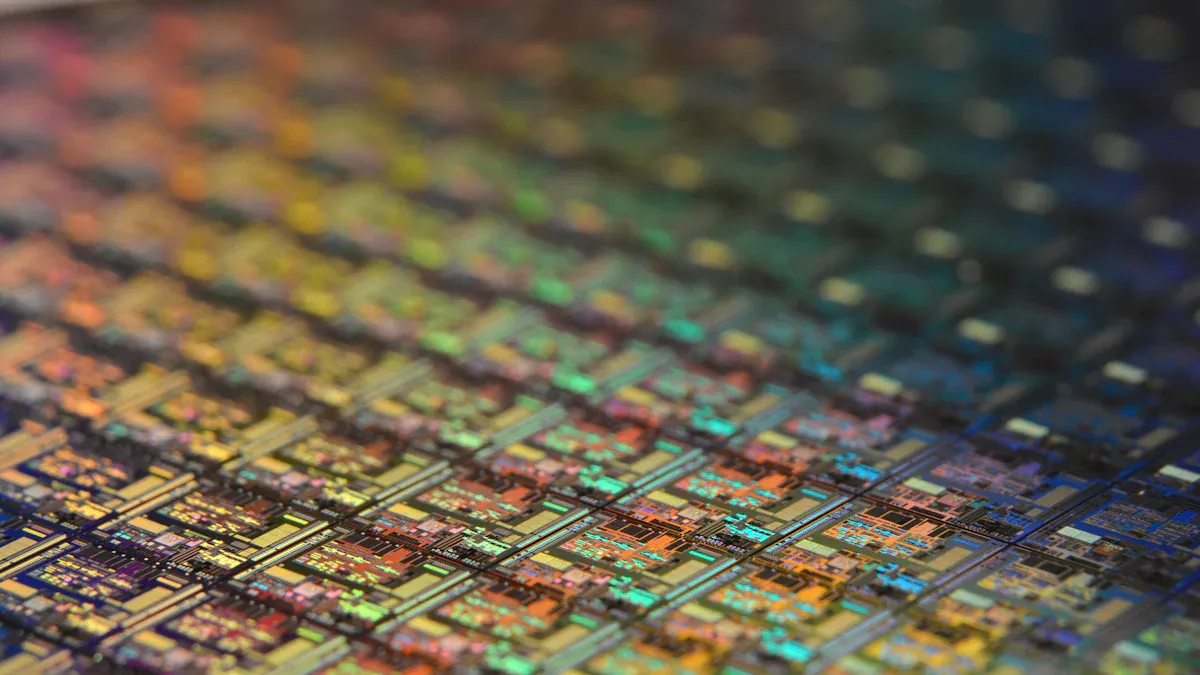

CVD SiC coating provides a robust shield for your semiconductor processing equipment. Manufacturing environments often expose tools to abrasive particles and corrosive chemicals. These conditions can degrade unprotected surfaces, leading to frequent repairs. By applying CVD SiC coating, you create a barrier that resists wear and corrosion.

This protection ensures your equipment maintains its precision over time. For example, components like chamber walls and gas distribution plates benefit from the coating’s durability. You can rely on these tools to perform consistently, even under demanding conditions.

Tip: Regularly inspect coated equipment to identify any signs of wear early. This practice helps you maintain optimal performance.

High-Temperature and Plasma-Resistant Uses

Semiconductor manufacturing often involves high-temperature processes and plasma environments. CVD SiC coating excels in these applications. Its thermal stability allows your equipment to withstand extreme heat without losing functionality.

Plasma resistance is another key advantage. Plasma can erode unprotected surfaces, reducing their lifespan. CVD SiC coating resists this erosion, ensuring your tools remain effective. This makes it ideal for components like plasma etching chambers and wafer carriers.

Note: Using CVD SiC-coated tools reduces downtime caused by equipment failure, improving your production efficiency.

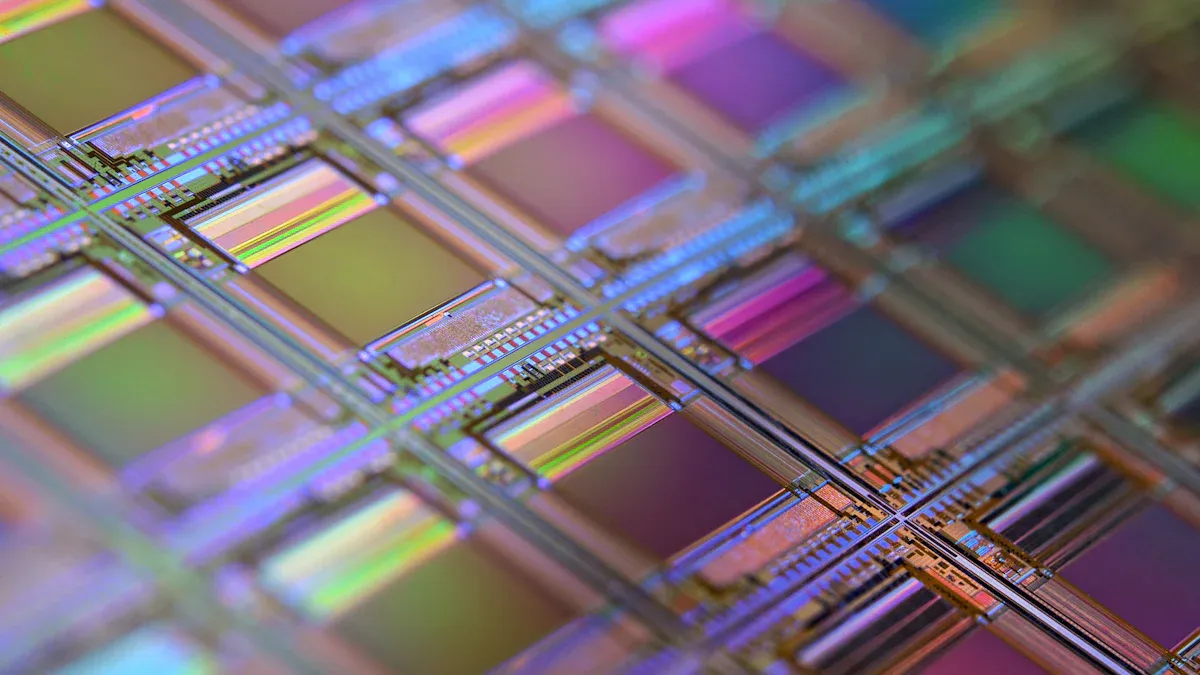

Wafer Handling and Etching Applications

Handling wafers requires precision and cleanliness. CVD SiC coating minimizes the risk of contamination by providing a chemically inert surface. This ensures your wafers remain free of impurities during processing.

In etching applications, the coating’s hardness and chemical resistance protect your tools from damage. This allows you to achieve precise etching results without compromising equipment integrity. By using CVD SiC-coated tools, you enhance both the quality and reliability of your manufacturing processes.

Reminder: Choose a coating provider with expertise in semiconductor applications to ensure the best results.

Technical Considerations for CVD SIC Coating

Choosing the Right Coating Provider

Selecting the right coating provider is critical for achieving optimal results. You should evaluate providers based on their expertise in semiconductor applications. Look for companies with a proven track record in delivering high-quality CVD SiC coatings.

Ask about their quality control processes. Reliable providers use advanced inspection techniques to ensure coatings meet industry standards. You should also inquire about their ability to customize coatings for your specific needs. A provider with flexible solutions can help you maximize the performance of your equipment.

Tip: Request samples or case studies to assess the provider’s capabilities before making a decision.

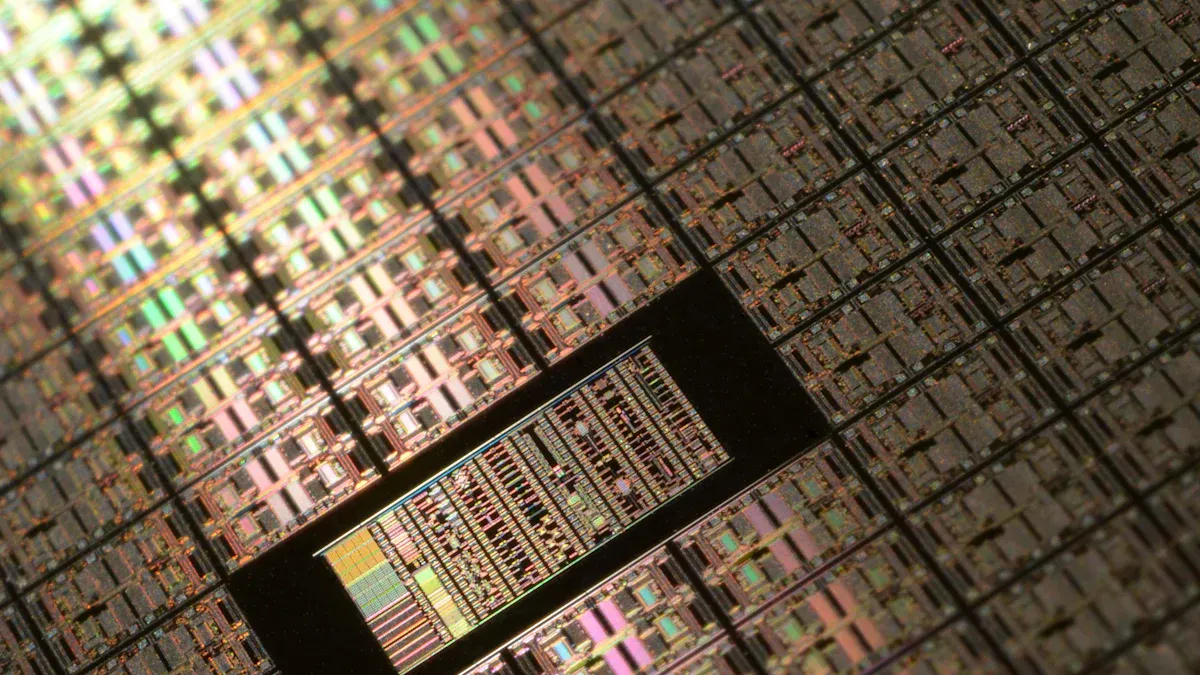

Ensuring Coating Thickness and Uniformity

Coating thickness and uniformity directly impact the performance of your equipment. Uneven coatings can lead to weak spots, reducing durability and effectiveness. You should work with your provider to specify the ideal thickness for your application.

Advanced deposition techniques, such as precision-controlled CVD processes, ensure uniform coatings. Regular inspections during production help identify any inconsistencies early. By prioritizing uniformity, you can avoid costly equipment failures and maintain consistent manufacturing quality.

Reminder: Use tools like profilometers to measure coating thickness and verify uniformity.

Maintenance and Inspection Best Practices

Proper maintenance extends the lifespan of your coated equipment. You should establish a routine inspection schedule to check for signs of wear or damage. Focus on areas exposed to high temperatures or corrosive chemicals.

Clean coated surfaces regularly to prevent contamination. Use non-abrasive cleaning methods to avoid damaging the protective layer. If you notice defects, address them promptly to prevent further deterioration.

Note: Partner with your coating provider for guidance on maintenance protocols tailored to your equipment.

Balancing Cost and Performance

Balancing cost and performance ensures you get the most value from your investment. You should compare the upfront cost of CVD SiC coating with its long-term benefits. While high-quality coatings may require a larger initial investment, they reduce maintenance expenses and extend equipment lifespan.

Focus on the specific needs of your operation. For example, prioritize durability for tools exposed to harsh conditions. By aligning coating features with your requirements, you can achieve cost-effective solutions without compromising performance.

Tip: Conduct a cost-benefit analysis to evaluate the financial impact of CVD SiC coating on your operations.

CVD SIC Coating offers unmatched durability, thermal stability, and chemical resistance. It protects your equipment, extends its lifespan, and reduces costs. Its applications in semiconductor manufacturing ensure precision and reliability. By adopting this coating, you can enhance productivity and achieve better outcomes in high-precision operations. Choose this solution for long-term success.

FAQ

What is the typical lifespan of CVD SiC-coated equipment?

CVD SiC-coated equipment lasts significantly longer than uncoated tools. With proper maintenance, you can expect extended durability, often exceeding several years of reliable performance.

Can CVD SiC coating be applied to all semiconductor tools?

CVD SiC coating works on most semiconductor tools, including chamber walls and wafer carriers. However, consult your provider to confirm compatibility with your specific equipment.

How do I ensure the coating remains effective over time?

Inspect coated surfaces regularly for wear or damage. Clean them using non-abrasive methods. Partner with your coating provider for tailored maintenance advice.