Industrial applications depend on advanced coating technologies to improve durability and efficiency. TAC COATING plays a crucial role in achieving superior performance. CVD TAC COATING stands out for its exceptional wear resistance and adhesion, while also offering reliable solutions for demanding applications. Additionally, CVD SIC COATING delivers unmatched advantages in high-temperature environments, making it indispensable for precision industries. Choosing the appropriate TAC COATING ensures optimal results and long-term cost savings.

Key Takeaways

- CVD TAC is very strong and lasts longer. It works well for tough jobs in planes and cars.

- PVD TAC costs less and works better on heat-sensitive stuff. It makes surfaces hard and look nice.

- Pick a coating by thinking about use, material, and cost. This helps it work best and saves money.

Overview of TAC COATING Technologies

What is CVD TAC?

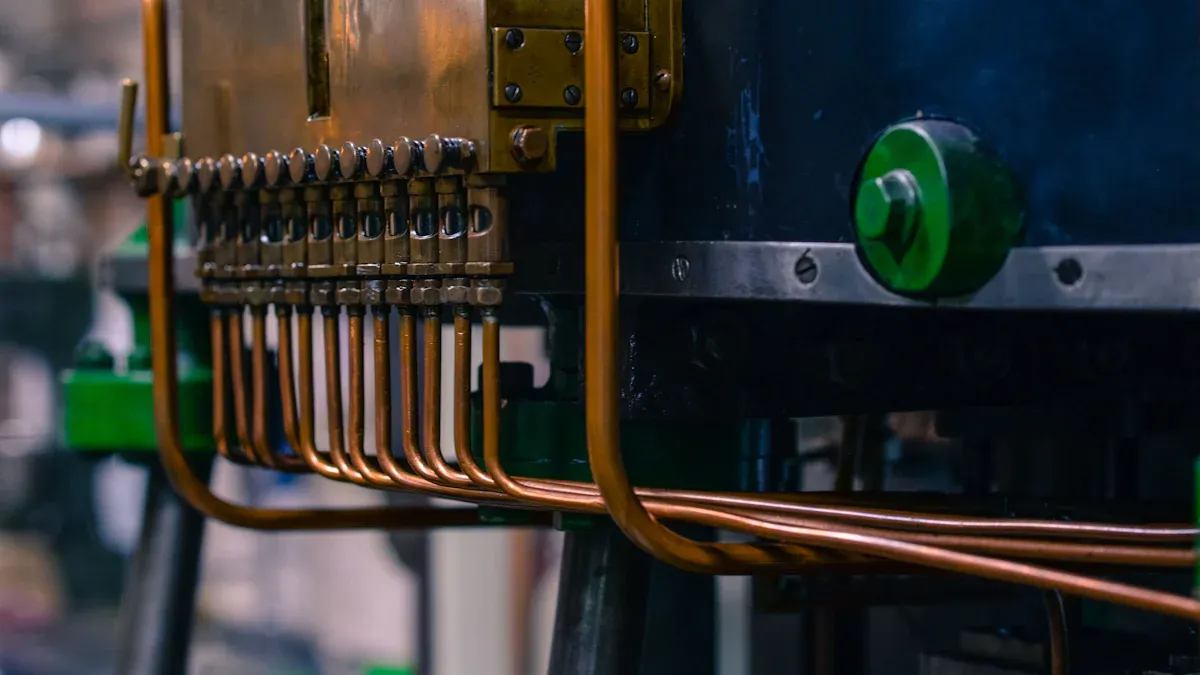

CVD TAC, or Chemical Vapor Deposition TAC, is a coating process that involves the chemical reaction of gaseous precursors on a substrate’s surface. This method creates a thin, uniform layer with exceptional adhesion and durability. The process occurs at high temperatures, which allows the coating to bond strongly with the substrate. Industries often use CVD TAC for applications requiring resistance to wear, corrosion, and extreme temperatures. Its ability to form dense and defect-free coatings makes it a preferred choice for precision tools and components.

What is PVD TAC?

PVD TAC, or Physical Vapor Deposition TAC, is a vacuum-based coating technique. It involves the physical transfer of material from a solid source to the substrate. Unlike CVD TAC, PVD TAC operates at lower temperatures, making it suitable for heat-sensitive materials. This method produces coatings with excellent hardness and smoothness. PVD TAC is widely used in decorative applications, cutting tools, and medical devices due to its ability to enhance surface properties without altering the substrate’s core characteristics.

Key industrial applications of CVD TAC and PVD TAC

CVD TAC finds extensive use in industries such as aerospace, automotive, and electronics. It is ideal for components exposed to high stress and temperature, such as turbine blades and semiconductor wafers. PVD TAC, on the other hand, is commonly applied in the manufacturing of cutting tools, optical lenses, and medical implants. Both TAC COATING methods play a crucial role in improving product performance and extending service life across various sectors.

Performance Comparison of CVD TAC and PVD TAC

Durability and wear resistance

Durability and wear resistance are critical factors in evaluating coating technologies. CVD TAC demonstrates exceptional performance in high-stress environments. Its dense and defect-free structure ensures prolonged resistance to wear and abrasion. This makes it ideal for components exposed to extreme mechanical loads, such as cutting tools and turbine blades.

PVD TAC, while also offering excellent wear resistance, performs better in applications requiring surface hardness rather than bulk durability. Its lower processing temperature allows it to coat heat-sensitive materials effectively. However, PVD TAC may not match the long-term durability of CVD TAC in highly abrasive conditions.

Cost Analysis of TAC COATING Methods

Initial investment and setup costs

The initial investment for TAC COATING technologies varies significantly between CVD TAC and PVD TAC. CVD TAC requires high-temperature reactors and advanced chemical handling systems. These systems demand a substantial upfront cost due to their complexity and the need for precise control mechanisms. Additionally, the installation process for CVD TAC equipment often involves specialized infrastructure, such as high-temperature-resistant chambers and gas supply systems.

PVD TAC, on the other hand, involves a vacuum-based setup. While the equipment for PVD TAC is less complex than that of CVD TAC, it still requires a significant investment. The vacuum chambers and deposition sources used in PVD TAC are expensive, though they generally cost less than the high-temperature systems required for CVD TAC. Companies must carefully evaluate their budget and production needs before committing to either technology.

Operational and maintenance costs

Operational costs for TAC COATING methods depend on factors such as energy consumption, material usage, and labor requirements. CVD TAC processes consume more energy due to the high temperatures needed for chemical reactions. This results in higher electricity costs and increased wear on equipment components, leading to frequent maintenance. The use of reactive gases in CVD TAC also necessitates strict safety protocols, which can add to operational expenses.

PVD TAC, with its lower operating temperatures, consumes less energy. This makes it a more cost-effective option for companies aiming to reduce energy expenses. Maintenance costs for PVD TAC equipment are also lower, as the process involves fewer high-stress conditions. However, the need for vacuum system upkeep and periodic replacement of deposition materials can still contribute to operational expenses.

Long-term savings and ROI

Both CVD TAC and PVD TAC offer long-term savings by extending the lifespan of coated components. CVD TAC provides superior durability and wear resistance, which reduces the frequency of part replacements in high-stress applications. This translates to significant cost savings over time, especially in industries like aerospace and automotive, where component reliability is critical.

PVD TAC, while not as durable as CVD TAC in extreme conditions, excels in applications requiring surface hardness and aesthetic appeal. Its lower energy consumption and maintenance costs contribute to a faster return on investment for companies using it in less demanding environments. By carefully analyzing their operational needs and long-term goals, businesses can maximize ROI with the appropriate TAC COATING technology.

Recommendations for Choosing the Right TAC COATING Technology

Factors to consider for industrial applications

Selecting the right coating technology depends on several critical factors. Each industrial application has unique requirements, and understanding these needs ensures optimal performance and cost efficiency.

-

Operating Environment: The conditions in which the coated components will function play a significant role. High-temperature environments, such as those in aerospace or automotive industries, benefit from the superior thermal resistance of CVD TAC. Conversely, applications involving heat-sensitive materials may require the lower-temperature process of PVD TAC.

-

Material Compatibility: The substrate material determines the suitability of the coating method. CVD TAC works well with materials that can withstand high temperatures, while PVD TAC is ideal for substrates prone to thermal damage.

-

Performance Requirements: Industries requiring extreme wear resistance and durability, such as heavy machinery or cutting tools, often prefer CVD TAC. For applications prioritizing surface hardness or aesthetic appeal, PVD TAC offers a better solution.

-

Budget Constraints: Initial investment, operational costs, and long-term savings must align with the company’s financial goals. Businesses with limited budgets may lean toward PVD TAC due to its lower energy consumption and maintenance costs.

-

Environmental Considerations: Sustainability is becoming increasingly important. Companies aiming to reduce their environmental footprint should evaluate the ecological impact of each coating method. PVD TAC, with its lower energy usage, may align better with green initiatives.

Tip: Conducting a thorough cost-benefit analysis helps businesses make informed decisions tailored to their specific needs.

CVD TAC excels in durability and wear resistance, making it ideal for high-stress applications. PVD TAC offers lower costs and better compatibility with heat-sensitive materials.

Recommendation: Companies should assess operating conditions, material compatibility, and budget constraints. For extreme durability, CVD TAC is preferred. For aesthetic or surface hardness needs, PVD TAC provides a cost-effective solution.

FAQ

What are the main differences between CVD TAC and PVD TAC?

CVD TAC uses high temperatures and chemical reactions for dense coatings. PVD TAC operates at lower temperatures, offering smoother finishes and compatibility with heat-sensitive materials.

Which coating method is more environmentally friendly?

PVD TAC is more eco-friendly due to its lower energy consumption and reduced emissions. CVD TAC requires higher energy input, increasing its environmental impact.

How can businesses decide between CVD TAC and PVD TAC?

Businesses should evaluate operating conditions, material compatibility, and budget. CVD TAC suits high-stress environments, while PVD TAC works better for heat-sensitive or aesthetic applications.

Tip: Consult with coating experts to align technology selection with specific industrial needs.