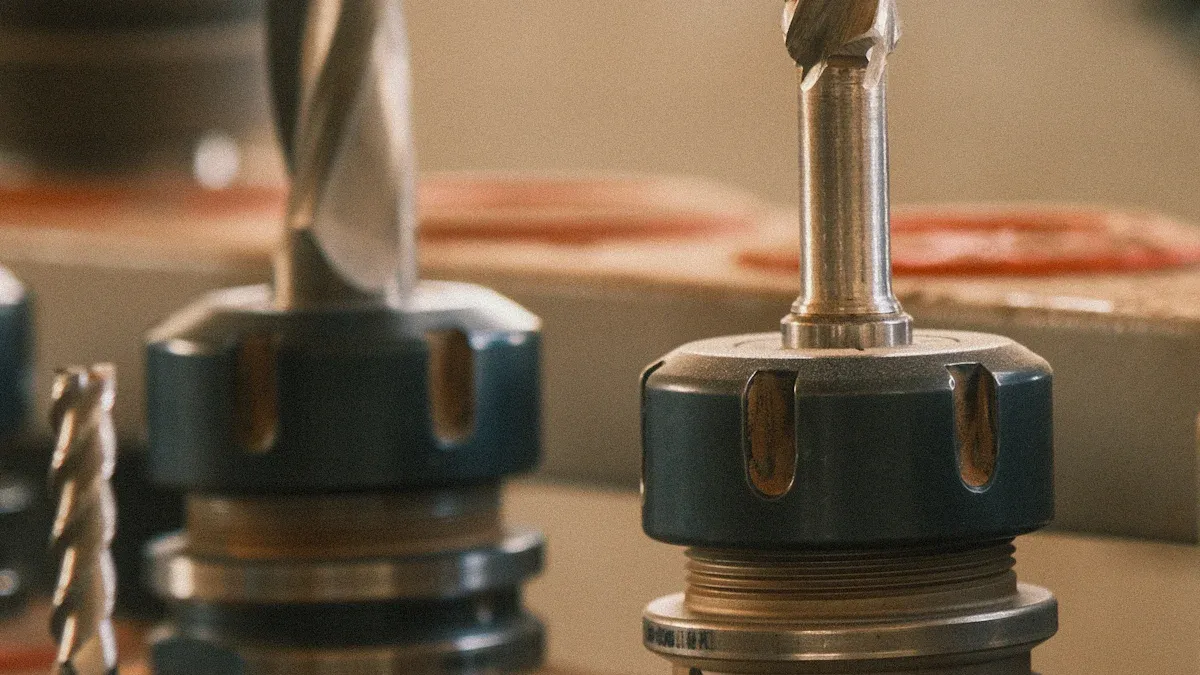

Precision tools demand coatings that enhance their performance and durability. Achieving sub-micron thickness in CVD TAC Coating ensures these tools operate with unmatched accuracy. However, traditional processes often struggle to maintain uniformity at such fine scales. You need innovative techniques to overcome these limitations and unlock the full potential of precision tools.

Key Takeaways

- Very thin CVD TAC coatings make tools work better. They create smooth surfaces that lower friction and boost precision.

- New methods, like plasma-assisted techniques, apply coatings faster. These methods also help control coating features, making them great for tough conditions.

- Special coatings are made for different industries to solve problems. For example, they handle heat in aerospace or are safe for medical use.

Advancements in Deposition Techniques

Enhanced Chemical Vapor Deposition Methods

Chemical Vapor Deposition (CVD) has evolved significantly to meet the demands of precision tools. You can now achieve sub-micron thickness with advanced methods that focus on controlling deposition rates and material uniformity. These improvements ensure that coatings like CVD TAC Coating adhere consistently to tool surfaces, enhancing their performance.

Modern CVD techniques use optimized gas flow systems to distribute coating materials evenly. This prevents uneven layers and reduces defects. For example, multi-zone reactors allow you to control temperature and pressure in different areas, ensuring precise layer formation.

Tip: When selecting a CVD method, prioritize systems that offer adjustable parameters. This flexibility helps you achieve the exact thickness required for your tools.

Another breakthrough involves the use of precursor materials tailored for sub-micron coatings. These materials decompose efficiently during the deposition process, leaving behind a smooth and durable layer. You can rely on these advancements to create coatings that meet the highest standards of precision.

Plasma-Assisted Deposition Technologies

Plasma-assisted deposition technologies take CVD to the next level. By introducing plasma into the process, you can achieve faster deposition rates and better control over coating properties. Plasma enhances the energy of the reaction, allowing materials like titanium aluminum carbon to bond more effectively.

This method is particularly useful for creating nano-structured coatings. Plasma generates high-energy ions that interact with the surface, forming layers with exceptional hardness and wear resistance. You’ll find this especially beneficial for tools used in high-stress environments.

Plasma-assisted techniques also reduce the need for high temperatures. Lower temperatures minimize thermal stress on the substrate, preserving the integrity of your tools. This makes the process suitable for delicate applications where precision is critical.

| Feature | Enhanced CVD | Plasma-Assisted Deposition |

|---|---|---|

| Deposition Rate | Moderate | High |

| Temperature Requirements | High | Low |

| Layer Uniformity | Excellent | Excellent |

| Ideal Applications | General Precision Tools | High-Stress Environments |

Note: Plasma-assisted deposition is ideal for industries requiring ultra-thin coatings with superior durability, such as aerospace and medical tools.

Innovations in Material Science for CVD TAC Coating

Development of Titanium Aluminum Carbon Alloys

You can achieve remarkable improvements in coating performance by using advanced titanium aluminum carbon (Ti-Al-C) alloys. These alloys form the backbone of modern CVD TAC Coating, offering a unique combination of strength, heat resistance, and wear protection. Researchers have fine-tuned the composition of these alloys to enhance their bonding properties during the deposition process. This ensures a uniform and durable coating layer, even at sub-micron thickness.

One key advantage of Ti-Al-C alloys is their ability to withstand extreme conditions. Whether your tools operate in high-temperature environments or face constant mechanical stress, these alloys provide reliable protection. Their lightweight nature also minimizes the impact on tool performance, making them ideal for precision applications.

Did you know? Ti-Al-C alloys are often used in aerospace and automotive industries due to their exceptional durability and thermal stability.

Nano-Structured Coating Materials

Nano-structured materials represent a breakthrough in CVD TAC Coating technology. These materials consist of ultra-fine particles that create a dense and uniform layer on the tool surface. You benefit from coatings that are not only harder but also more resistant to wear and corrosion.

The secret lies in the nanoscale structure. Smaller particles fill gaps more effectively, reducing surface defects and improving adhesion. This results in a smoother finish, which enhances the precision of your tools. Nano-structured coatings also allow for better control over thickness, making them perfect for achieving sub-micron layers.

| Feature | Traditional Coatings | Nano-Structured Coatings |

|---|---|---|

| Hardness | Moderate | High |

| Surface Smoothness | Uneven | Excellent |

| Wear Resistance | Average | Superior |

By adopting nano-structured materials, you can extend the lifespan of your tools while maintaining their accuracy and efficiency.

Process Optimization for Sub-Micron Thickness

Precision Control in Layer Deposition

Achieving sub-micron thickness in coatings requires precise control over the deposition process. You need to focus on managing variables like temperature, pressure, and material flow rates. These factors directly influence the uniformity and quality of the coating. Advanced deposition systems now allow you to fine-tune these parameters with remarkable accuracy. This ensures that each layer of the CVD TAC Coating is consistent and meets the desired thickness.

One effective approach involves using automated systems. These systems can adjust deposition settings in real time, reducing the risk of errors. For example, multi-zone temperature controls help maintain consistent conditions across the entire substrate. This prevents uneven coatings and enhances the overall performance of your tools.

Tip: Regularly calibrate your equipment to ensure optimal performance. Small deviations in settings can significantly impact the final coating quality.

Real-Time Monitoring and Feedback Systems

Real-time monitoring plays a crucial role in optimizing the coating process. By using advanced sensors and feedback systems, you can track key parameters during deposition. These systems provide instant data on factors like layer thickness, material distribution, and surface quality. This allows you to make immediate adjustments, ensuring the coating remains within specifications.

Modern feedback systems use technologies like optical sensors and laser measurement tools. These tools offer precise readings, helping you maintain control over the process. For instance, if the system detects a deviation in thickness, it can automatically adjust the material flow rate. This minimizes waste and ensures a consistent coating.

Did you know? Real-time monitoring not only improves coating quality but also reduces production time. You can achieve better results in fewer cycles, saving both time and resources.

Benefits of Sub-Micron Thickness in Precision Tools

Improved Tool Performance and Accuracy

Sub-micron thickness in coatings plays a critical role in improving the performance of precision tools. When you apply a coating with such fine thickness, it creates a smoother and more uniform surface. This reduces friction during tool operation, allowing for more precise movements. For example, in cutting tools, a smoother surface ensures cleaner cuts and minimizes material deformation.

You also benefit from enhanced accuracy. Sub-micron coatings reduce irregularities that can interfere with the tool’s performance. This is especially important in industries like aerospace and medical devices, where even the smallest error can lead to significant consequences. A tool coated with sub-micron CVD TAC Coating delivers consistent results, ensuring reliability in high-stakes applications.

Tip: To maximize performance, pair sub-micron coatings with tools designed for precision tasks. This combination ensures optimal results in demanding environments.

Enhanced Durability and Wear Resistance

Sub-micron coatings significantly enhance the durability of your tools. The ultra-thin layer acts as a protective shield, preventing wear and tear caused by constant use. This is particularly beneficial for tools exposed to harsh conditions, such as high temperatures or abrasive materials. With a sub-micron CVD TAC Coating, your tools can withstand these challenges without compromising their functionality.

The wear resistance of sub-micron coatings also extends the lifespan of your tools. By reducing surface damage, the coating minimizes the need for frequent replacements. This not only saves you money but also reduces downtime in your operations. Additionally, the improved resistance to corrosion ensures that your tools remain effective even in chemically aggressive environments.

| Feature | Without Sub-Micron Coating | With Sub-Micron Coating |

|---|---|---|

| Durability | Moderate | High |

| Wear Resistance | Average | Superior |

| Lifespan | Short | Extended |

Did you know? Tools with sub-micron coatings often perform better in extreme conditions, making them a preferred choice in industries like manufacturing and automotive.

Customization and Application-Specific Coatings

Tailored Coatings for Industry-Specific Needs

Every industry has unique challenges, and your tools need coatings that address those specific demands. Customizing CVD TAC coatings allows you to optimize tool performance for your application. For example, tools used in the aerospace industry require coatings that withstand extreme temperatures and resist oxidation. In contrast, medical tools benefit from biocompatible coatings that ensure safety and precision during surgical procedures.

Tailored coatings also help you achieve better results in manufacturing. For instance, cutting tools in automotive production need coatings with high wear resistance to handle abrasive materials. By selecting the right coating composition and thickness, you can extend tool life and improve efficiency.

Tip: When choosing a coating, consider the operating environment and the material your tools will interact with. This ensures the coating meets your specific needs.

Custom solutions often involve adjusting the ratio of titanium, aluminum, and carbon in the coating. These adjustments enhance properties like hardness, corrosion resistance, or thermal stability. You can work with coating specialists to develop a solution that aligns with your goals.

Collaboration Between Manufacturers and End-Users

Collaboration plays a key role in creating effective coatings. By working closely with manufacturers, you can share insights about your tools’ performance and challenges. This feedback helps manufacturers refine their processes and deliver coatings that meet your expectations.

Manufacturers often conduct trials to test coatings in real-world conditions. These tests provide valuable data on durability, wear resistance, and overall performance. You can use this information to make informed decisions about the best coating for your tools.

Did you know? Many manufacturers now offer consultation services to help you identify the ideal coating for your application. This partnership ensures you get a solution tailored to your needs.

By fostering collaboration, you not only improve your tools but also contribute to advancements in coating technology.

Sustainability in CVD TAC Coating Processes

Energy-Efficient Deposition Techniques

Energy efficiency plays a vital role in making CVD TAC coating processes more sustainable. You can adopt advanced deposition systems designed to minimize energy consumption without compromising performance. These systems use optimized heating mechanisms that focus energy only where it is needed. This reduces waste and ensures consistent coating quality.

One effective method involves using low-temperature plasma-assisted deposition. This technique requires less energy compared to traditional high-temperature processes. It also reduces thermal stress on tools, which improves their longevity.

Tip: Look for deposition systems with energy-saving certifications. These systems often include features like automated energy management and real-time monitoring to further reduce power usage.

Another innovation is the use of renewable energy sources to power deposition equipment. Solar panels or wind energy can supply clean power, lowering the carbon footprint of your operations. By integrating these technologies, you contribute to a more sustainable manufacturing process.

Reduction of Waste and Environmental Impact

Reducing waste is another critical aspect of sustainable CVD TAC coating processes. You can achieve this by adopting closed-loop systems that recycle unused coating materials. These systems capture excess material during deposition and reintroduce it into the process, minimizing waste.

Using eco-friendly precursor materials also helps reduce environmental impact. These materials decompose cleanly, leaving fewer harmful byproducts. This makes the process safer for both workers and the environment.

Did you know? Some manufacturers now offer biodegradable precursors for CVD coatings. These materials break down naturally, reducing long-term environmental harm.

Additionally, precise control over deposition parameters ensures minimal material usage. By applying only the required amount of coating, you avoid overuse and reduce waste. This not only benefits the environment but also lowers production costs.

Sub-micron CVD TAC Coating has revolutionized precision tools by enhancing their performance and durability. You can expect future innovations to focus on smarter, more efficient processes. These advancements will address evolving industry needs, ensuring tools remain reliable and sustainable in demanding applications. The possibilities for coating technologies are limitless.

FAQ

What is the main advantage of sub-micron CVD TAC coatings?

Sub-micron coatings improve tool precision and durability. They create smoother surfaces, reduce friction, and enhance wear resistance, making tools more reliable in demanding applications.

How do nano-structured materials enhance coating performance?

Nano-structured materials fill gaps effectively, creating dense layers. This improves hardness, adhesion, and corrosion resistance, ensuring tools last longer and perform better under stress.

Can CVD TAC coatings be customized for specific industries?

Yes, you can tailor coatings to meet industry needs. Adjusting material composition ensures tools withstand unique challenges, like extreme temperatures or biocompatibility for medical applications.