Electric vehicle (EV) battery production demands extreme precision and durability. You face challenges like ensuring accurate assembly while managing intense heat during the process. SiC robotic arms offer a breakthrough solution. Their advanced design, combined with the resilience of SiC coating, enables them to operate flawlessly in high-temperature environments while maintaining unmatched accuracy.

Key Takeaways

- SiC robotic arms improve accuracy in making EV batteries. They help avoid mistakes.

- SiC handles heat well, so robotic arms work in hot places without stopping often.

- Using SiC tech saves money on repairs and makes robotic arms last longer. This increases how much work gets done.

SiC Technology Overview

Silicon Carbide Properties

Silicon carbide (SiC) stands out as a material with exceptional properties. It combines high thermal conductivity with remarkable strength, making it ideal for demanding industrial applications. SiC resists wear and corrosion, ensuring durability even in harsh environments. Its ability to withstand extreme temperatures without losing structural integrity sets it apart from traditional materials.

Tip: SiC’s unique crystalline structure allows it to handle heat levels that would damage other materials. This makes it a game-changer for industries like EV battery production.

SiC also offers excellent electrical properties. It supports high-voltage operations while minimizing energy loss. This feature makes it a preferred choice for applications requiring efficiency and reliability.

Benefits for EV Applications

You’ll find SiC invaluable in EV battery production due to its ability to enhance both precision and performance. Its heat resistance ensures consistent operation during high-temperature processes, such as electrode assembly and thermal testing.

Here’s how SiC benefits EV applications:

- Improved Efficiency: SiC reduces energy waste, enabling faster and more accurate robotic movements.

- Enhanced Durability: Its resistance to wear and heat ensures longer operational life for robotic arms.

- Greater Reliability: SiC maintains performance under challenging conditions, reducing downtime and maintenance costs.

🚗 Fun Fact: SiC’s use in EVs isn’t limited to battery production. It’s also a key material in power electronics, helping improve charging speeds and energy conversion efficiency.

By leveraging SiC, you can achieve higher productivity and reliability in EV battery manufacturing, paving the way for a more sustainable future.

Precision in EV Battery Production

Enhanced Assembly Accuracy

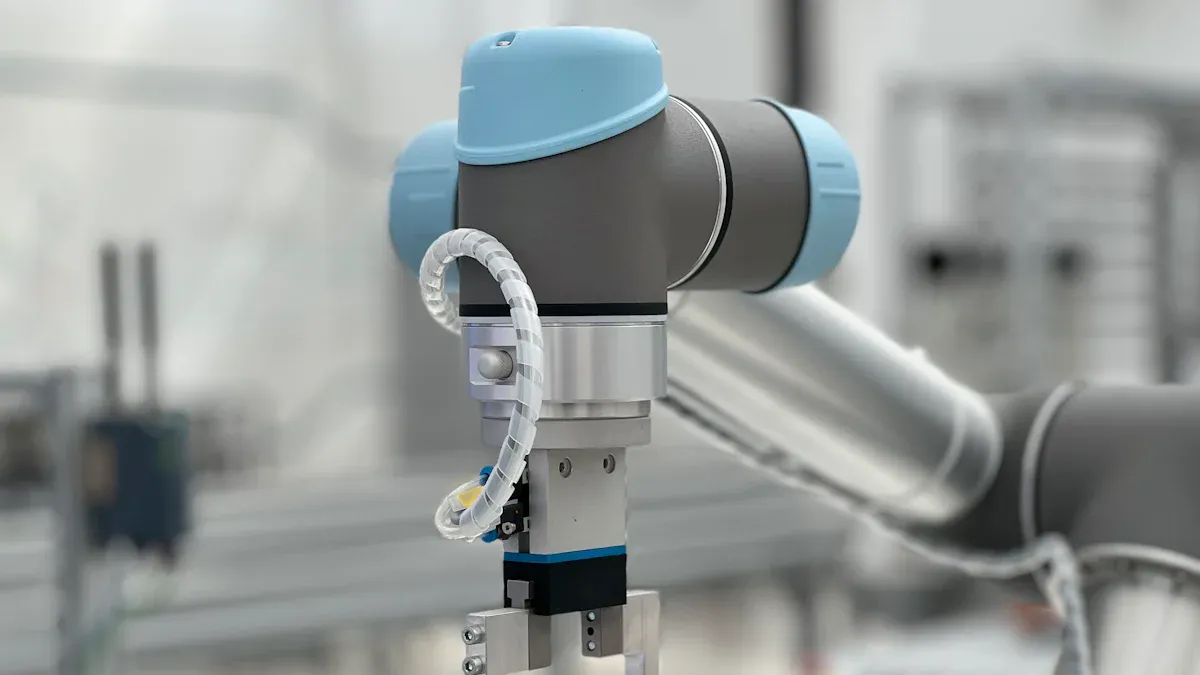

Precision plays a critical role in EV battery production. You need robotic arms that can handle intricate tasks like electrode placement and cell stacking with pinpoint accuracy. SiC robotic arms excel in this area. Their advanced design ensures smoother and more controlled movements, reducing errors during assembly.

SiC’s unique properties enhance the performance of robotic arms. Its rigidity minimizes vibrations, allowing you to achieve consistent alignment of battery components. This precision directly impacts the efficiency and reliability of EV batteries, ensuring they meet stringent quality standards.

Note: Even minor misalignments in battery assembly can lead to performance issues or safety risks. SiC robotic arms help you avoid these pitfalls by delivering unmatched accuracy.

When paired with SiC coating, these robotic arms gain additional benefits. The coating improves wear resistance, ensuring the arms maintain their precision over extended periods of operation. This durability reduces the need for frequent recalibration, saving you time and resources.

Testing Consistency

Testing is another critical phase in EV battery production. You must ensure that every battery meets performance and safety benchmarks. SiC robotic arms streamline this process by offering consistent and reliable testing capabilities.

Their heat resistance allows them to operate effectively during thermal testing, where batteries are exposed to high temperatures to evaluate their durability. SiC coating further enhances this capability, protecting the robotic arms from wear and tear caused by repeated exposure to heat.

Tip: SiC robotic arms can handle repetitive testing tasks without losing accuracy, making them ideal for high-volume production lines.

These robotic arms also excel in electrical testing. Their precision ensures accurate measurements of voltage, current, and other parameters, helping you identify any defects early in the production process. By automating these tests, you can achieve faster turnaround times while maintaining high-quality standards.

Incorporating SiC technology into your testing processes not only improves consistency but also boosts overall productivity. You can rely on these robotic arms to deliver dependable results, ensuring your EV batteries perform optimally in real-world conditions.

Heat Resistance and SiC Coating

High-Temperature Durability

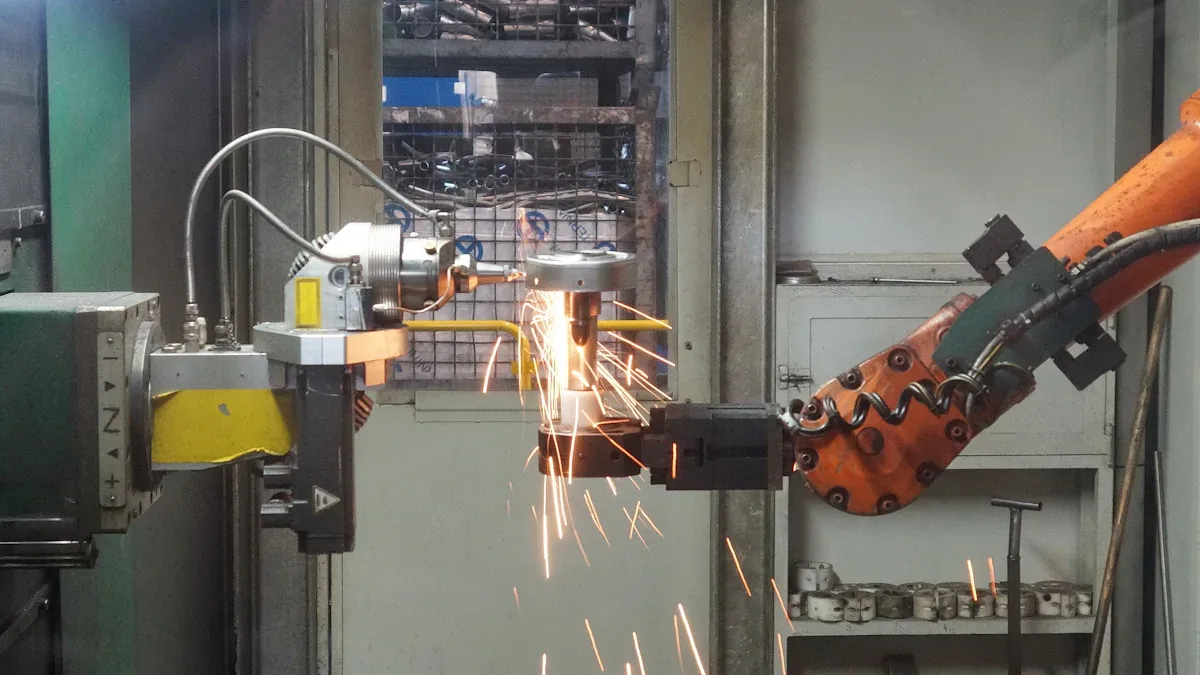

In EV battery production, high temperatures are unavoidable. Processes like electrode assembly and thermal testing generate intense heat that can damage equipment over time. You need tools that can endure these conditions without compromising performance. SiC robotic arms excel in this area due to their exceptional heat resistance.

Silicon carbide’s crystalline structure allows it to maintain its strength and stability even at extreme temperatures. Unlike traditional materials, SiC doesn’t warp or degrade when exposed to prolonged heat. This durability ensures that your robotic arms can operate reliably during demanding tasks.

Tip: Using SiC robotic arms reduces the risk of overheating, which can lead to costly downtime or equipment failure.

SiC’s thermal conductivity also plays a crucial role. It dissipates heat efficiently, preventing localized hotspots that could affect the precision of your operations. This feature makes SiC robotic arms ideal for high-temperature environments, ensuring consistent performance throughout the production cycle.

Role of SiC Coating in Performance

SiC coating enhances the capabilities of robotic arms by adding an extra layer of protection. This coating shields the arms from wear and tear caused by repeated exposure to heat and friction. You’ll notice that SiC-coated robotic arms maintain their precision and efficiency even after extended use.

The coating’s high-temperature tolerance ensures that the robotic arms can handle tasks like thermal testing without losing accuracy. It also improves the arms’ resistance to corrosion, which is essential in environments where chemicals or moisture are present.

Here’s how SiC coating boosts performance:

- Extended Lifespan: The coating minimizes wear, reducing the need for frequent replacements.

- Improved Precision: It prevents surface degradation, ensuring consistent accuracy during operations.

- Enhanced Reliability: SiC coating protects against environmental factors, keeping your equipment functional in challenging conditions.

Note: Investing in SiC-coated robotic arms not only improves performance but also lowers maintenance costs over time.

By incorporating SiC coating into your equipment, you can achieve higher productivity and reliability. This technology ensures that your robotic arms remain efficient and durable, even in the most demanding production environments.

Comparing SiC to Traditional Materials

Silicon-Based Alternatives

Silicon has long been the go-to material for industrial applications, including robotic arms. Its availability and cost-effectiveness make it a popular choice. However, silicon struggles in high-temperature environments. It tends to lose strength and stability when exposed to prolonged heat, which can lead to equipment failure.

In EV battery production, silicon-based robotic arms often require frequent maintenance. Their inability to handle extreme conditions limits their lifespan and reliability. While silicon performs well in low-stress tasks, it falls short when precision and durability are critical.

Did You Know? Silicon’s thermal conductivity is significantly lower than that of silicon carbide. This makes it less effective at dissipating heat, which is crucial in high-temperature processes.

Performance Advantages

SiC robotic arms outperform silicon-based alternatives in nearly every aspect. Their heat resistance ensures consistent performance during demanding tasks like electrode assembly and thermal testing. Unlike silicon, SiC maintains its structural integrity even under extreme conditions.

The addition of SIC COATING further enhances these advantages. This coating protects the robotic arms from wear and tear, extending their operational life. You’ll notice fewer breakdowns and reduced maintenance costs when using SiC-coated equipment.

Here’s a quick comparison of SiC and silicon:

| Feature | Silicon | Silicon Carbide (SiC) |

|---|---|---|

| Heat Resistance | Moderate | Exceptional |

| Durability | Limited | Long-lasting |

| Maintenance Frequency | High | Low |

By choosing SiC robotic arms, you gain a reliable solution that excels in precision, durability, and heat management. These advantages make SiC the superior choice for EV battery production.

Industrial Applications

Use Cases in EV Battery Lines

SiC robotic arms have become indispensable in EV battery production lines. Their precision and durability make them ideal for handling intricate tasks. You can use these robotic arms for electrode assembly, where accurate placement is critical. They also excel in cell stacking, ensuring uniform alignment to maintain battery performance.

Another key application is thermal testing. SiC robotic arms withstand high temperatures, allowing you to test battery durability without interruptions. Their heat resistance ensures consistent performance, even during prolonged testing cycles.

Tip: SiC robotic arms are perfect for repetitive tasks like welding and sealing. Their wear resistance reduces the need for frequent maintenance, saving you time and resources.

You’ll also find these robotic arms useful in quality control. They can perform precise measurements and inspections, helping you identify defects early. This ensures that only high-quality batteries reach the market.

Scalability for Mass Production

As EV demand grows, scaling up production becomes essential. SiC robotic arms offer the reliability and efficiency you need for mass production. Their durability allows them to operate continuously, minimizing downtime on your production line.

You can easily integrate these robotic arms into automated systems. Their compatibility with advanced software ensures seamless coordination across multiple production stages. This makes it easier for you to scale operations without compromising quality.

Did You Know? SiC robotic arms can handle high-speed tasks without losing accuracy. This makes them ideal for meeting the demands of large-scale manufacturing.

By adopting SiC technology, you can achieve higher output while maintaining precision. These robotic arms provide a scalable solution that supports the growing EV industry.

Future of SiC Technology

Innovations in SiC Materials

The future of silicon carbide (SiC) technology looks promising, with ongoing research driving exciting advancements. Scientists are developing new SiC composites that enhance strength and thermal conductivity. These materials aim to push the limits of what SiC can achieve in high-performance applications.

You’ll also see innovations in SiC manufacturing processes. Techniques like additive manufacturing (3D printing) are making it easier to create complex SiC components with precision. This reduces waste and lowers production costs, making SiC more accessible for industries like EV battery production.

Fun Fact: Researchers are exploring nano-engineered SiC materials. These could offer even greater durability and heat resistance, opening doors to applications in aerospace and beyond.

Another area of innovation involves improving SiC’s electrical properties. Enhanced designs are enabling better energy efficiency, which is crucial for EV systems. These breakthroughs ensure that SiC remains at the forefront of material science.

Impact on EV Industry Growth

SiC technology is set to revolutionize the EV industry. By improving the efficiency of robotic arms, it helps you produce batteries faster and with greater precision. This directly supports the growing demand for EVs worldwide.

You’ll also notice that SiC’s role extends beyond manufacturing. Its use in EV power electronics boosts charging speeds and energy conversion rates. This makes EVs more appealing to consumers, accelerating their adoption.

Tip: SiC’s durability reduces maintenance costs, making EV production more cost-effective.

As SiC technology evolves, it will drive innovation across the EV supply chain. You can expect faster production cycles, better-performing vehicles, and a more sustainable future for transportation. 🚗

SiC robotic arms offer unmatched precision and heat resistance. You can rely on them to improve assembly accuracy and testing consistency while reducing downtime. Their durability ensures long-term reliability in EV battery production.

Tip: SiC advancements promise even greater efficiency and sustainability, paving the way for innovative EV technologies.

Future developments in SiC materials will enhance manufacturing processes and accelerate EV industry growth. By adopting SiC technology, you contribute to a cleaner, more efficient transportation future.

FAQ

What makes SiC robotic arms better than traditional ones?

SiC robotic arms offer superior heat resistance, durability, and precision. These features make them ideal for high-temperature and high-accuracy tasks in EV battery production.

Can SiC robotic arms handle mass production demands?

Yes, they excel in scalability. Their durability and efficiency allow continuous operation, making them perfect for high-speed, large-scale EV battery manufacturing.

Tip: SiC robotic arms reduce downtime and maintenance, ensuring smooth production cycles.

Are SiC robotic arms cost-effective in the long run?

Absolutely! Their extended lifespan and reduced maintenance needs lower operational costs, making them a smart investment for EV battery production lines.

🚗 Fun Fact: SiC technology not only saves money but also boosts productivity!