Facilities in hazardous environments depend on reliable emergency Explosion Proof Telephone systems for safety. Outdated equipment or non-compliant installations can lead to accidents, chemical exposure, and costly shutdowns. OSHA reported thousands of violations in hazard communication, showing how common these failures are. Certified solutions like a mining Explosion Proof Telephone or an ATEX Explosion Proof Telephone protect workers and maintain compliance.

Signs Your Facility Needs an Emergency Explosion Proof Telephone Upgrade

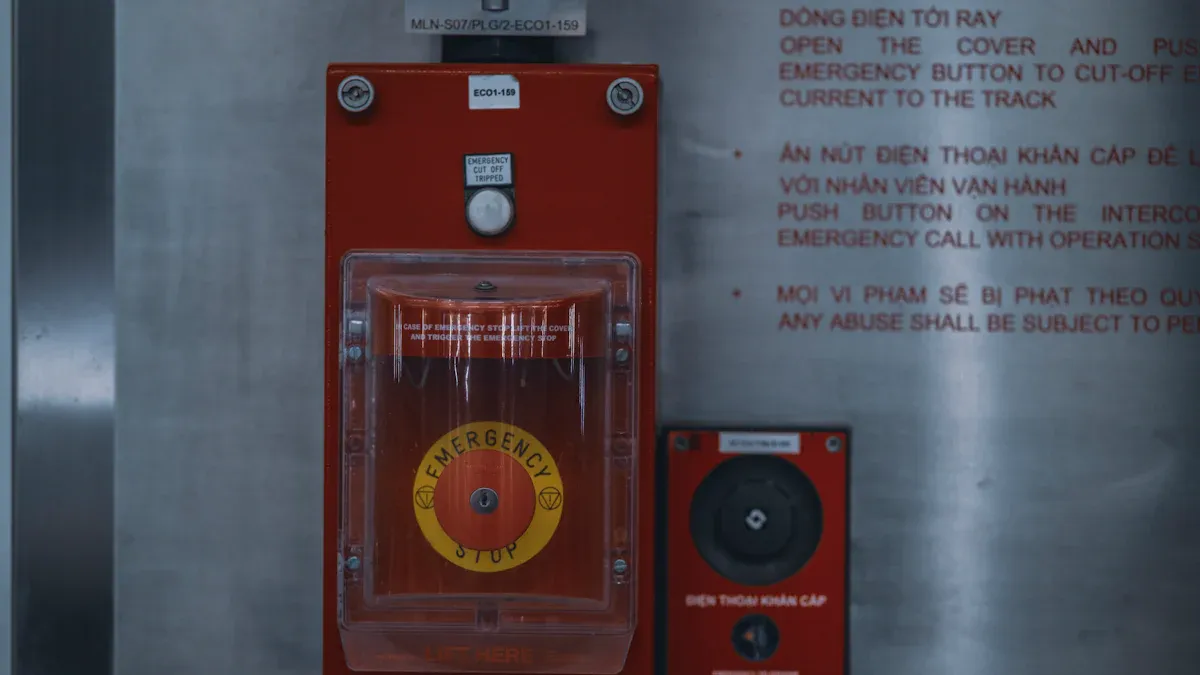

Outdated or Non-Compliant Emergency Telephone Systems

Many facilities still use old or non-compliant emergency telephone systems. These systems may not meet current safety standards. They can fail during emergencies, putting workers at risk. Some phones may not have the right certifications for hazardous areas. When a facility uses an outdated emergency Explosion Proof Telephone, it cannot guarantee reliable communication. Regular inspections help spot these problems early.

Operational Changes or Facility Expansion

Facilities often change their operations or expand their buildings. These changes can affect emergency communication needs. Operational changes, such as new processes or equipment, happen more often than major facility upgrades. They require updates to emergency procedures and training. Facility expansions or improvements to emergency preparedness equipment cost more and occur less often. However, both situations may require new or upgraded emergency Explosion Proof Telephone systems to keep everyone safe.

Findings from Safety Audits or Incident Reports

Safety audits and incident reports provide valuable information. They can reveal gaps in emergency communication systems. Audits may show that some phones do not work or lack proper certification. Incident reports might highlight times when workers could not reach help quickly. Facility managers should review these findings and act quickly. Upgrading to a certified emergency Explosion Proof Telephone can address these issues and improve overall safety.

Compliance and Risk Assessment for Emergency Explosion Proof Telephone Selection

Understanding Hazardous Area Classifications (Zones and Divisions)

Hazardous areas in industrial settings can contain gases, vapors, or dust that may ignite. Safety experts classify these areas to help facilities choose the right emergency Explosion Proof Telephone. In North America, the Division system uses Class 1 Division 1 for places where dangerous atmospheres are present often, and Division 2 for areas where hazards are rare during normal work. International standards use Zones. For gases, Zone 0 means an explosive atmosphere is present all the time, Zone 1 means it is likely during normal operations, and Zone 2 means it is unlikely and short-lived. For dust, Zone 20 is the most dangerous, with dust present often, while Zones 21 and 22 are less risky. These classifications guide which phones and equipment are safe to use.

Explosion-proof protection uses strong enclosures to contain any explosion inside the device. Intrinsically safe protection makes sure the phone cannot create sparks or heat that could start a fire. Facilities must match the phone’s protection type to the area’s classification. Proper marking on the phone shows it is safe for that specific hazardous location.

Tip: Always check the area’s classification before selecting or installing an emergency Explosion Proof Telephone.

Key Certification Standards: ATEX, UL, IECEx

Choosing the right emergency phone means understanding certification standards. Three main standards exist: ATEX, UL, and IECEx. Each one covers different regions and has unique rules for testing and marking devices.

| Aspect | ATEX Certification | UL Certification | IECEx Certification |

|---|---|---|---|

| Regional Scope | European Union (EU) | North America (US and Canada) | Global, international standard |

| Certification Process | Assessment with notified bodies; CE and Ex markings | Testing by NRTL; UL mark | Harmonized testing and certification; IECEx mark |

| Classification System | Groups and Categories (e.g., Group I for mining, Group II for other industries; Categories 1-3 by risk) | Classes (I, II, III), Divisions (1 or 2), Groups (A-D) | Similar to ATEX zones and categories |

| Marking Requirements | Ex symbol, group, category, temperature class | UL logo, class, division, group codes | IECEx mark for IEC standards |

| Conformity Assessment | Risk assessments, technical dossier, quality control | Product evaluation, factory inspections | Uniform safety standards, international acceptance |

| Usage | Mandatory in EU explosive atmospheres | Required in North American hazardous locations | Used globally for international compliance |

| Manufacturer Considerations | Needed for EU market; comprehensive process | Essential for North America; recognized by regulators | Enables global market access |

Facilities must select phones with the right certification for their region. For example, a plant in the US needs UL-certified phones, while a European site requires ATEX. IECEx certification helps companies that operate worldwide.

Evaluating Environmental and Operational Requirements

Selecting an emergency Explosion Proof Telephone involves more than just checking certifications. Facilities must consider many environmental and operational factors to ensure safety and reliability.

- Risk assessment helps limit explosion hazards.

- Area zoning classification ensures the phone matches the specific hazardous location.

- Temperature rating guarantees safe operation in extreme heat or cold.

- Protection against dust contamination prevents ignition from dust particles.

- Spark-proof technology avoids ignition from electrical sparks.

- Material selection matters, especially in corrosive or wet environments.

- Compliance with safety standards like IECEx, ATEX, NEC, and NFPA is essential.

- Compatibility with other devices prevents unsafe interactions.

- Maintenance and repair obligations keep the phone working safely.

- Operational factors such as weight, size, and power requirements affect installation and use.

Environmental conditions like temperature, humidity, and chemical exposure can impact phone performance. Explosion-proof phones often feature rugged designs, waterproof and dustproof ratings (such as IP66), and wide operating temperature ranges from -40°C to +70°C. These features help the phone work reliably in harsh settings.

Note: Regular inspections, proper installation, and staff training are key to keeping emergency phones safe and functional.

How to Choose the Right Emergency Explosion Proof Telephone

Matching Features to Facility Risk Level and Needs

Selecting the right emergency Explosion Proof Telephone starts with understanding the unique risks in each facility. Different industries face different hazards. For example, oil refineries and chemical plants often have explosive gases or dust. These environments require phones that prevent sparks and withstand harsh conditions. Facilities must match the phone’s features to their risk level.

The table below highlights the most critical features to consider:

| Feature | Description & Importance |

|---|---|

| Hazardous Location Classification | Match equipment to Class I, II, III and their divisions/zones for proper risk coverage. |

| Temperature Classification | Ensure the phone’s surface temperature stays below the ignition point of the surrounding atmosphere. |

| Robust Construction | Use heavy-duty enclosures like stainless steel or aluminum to contain explosions and resist damage. |

| Flame Paths | Design paths that cool escaping gases, stopping ignition outside the enclosure. |

| Conduit Sealing | Block gases or flames from traveling through wiring conduits to other areas. |

| Certification & Compliance | Follow standards such as NEC, IEC, UL, FM, and ATEX for verified safety. |

| Explosion Proof Enclosure Type | Choose from types like Flameproof (Ex d), Increased Safety (Ex e), Pressurized (Ex p), Non-Sparking (Ex n), or Powder Filled (Ex q) based on the environment. |

| Material Selection | Select corrosion-resistant materials like aluminum or stainless steel for durability. |

Facilities such as gasoline storage sites, refineries, and chemical plants need phones with non-sparking materials, airtight enclosures, and self-extinguishing parts. These features help prevent ignition and ensure safe communication. Some phones also offer SIP/VoIP compatibility, Power over Ethernet, weatherproof keypads, and noise-canceling microphones. These options improve usability and reliability in noisy, hazardous environments.

🛡️ Tip: Always match the phone’s features to the specific hazards and operational needs of your facility. Avoid choosing devices based only on price or appearance.

Ensuring Certification and Regulatory Compliance

Certification and compliance are not optional. They are legal requirements that protect lives and property. Each region has its own rules for explosion proof equipment. Facilities in the European Union must use ATEX-certified phones. North American sites need UL or CSA certifications. Global operations often require IECEx certification for broader acceptance.

- ATEX Certification: Mandatory in the EU. Ensures devices prevent ignition in explosive atmospheres.

- IECEx Certification: Recognized worldwide. Helps companies meet strict safety standards and access global markets.

- UL and CSA Certifications: Required in North America. Devices must pass tough tests for safety and reliability.

- Hazardous Area Classifications:

- Class I Division 1: Constant presence of ignitable gases or vapors.

- Zone 0: Continuous explosive atmosphere.

- Zone 1: Explosive atmosphere likely during normal operation.

- Zone 2: Explosive atmosphere possible but rare.

- Gas Group Classifications:

- Group I: Mining.

- Group II (IIA, IIB, IIC): Surface industries with different gas types.

- Dust Explosion Zones:

- Zone 20: Continuous dust.

- Zone 21: Dust likely during normal operation.

- Zone 22: Dust possible under abnormal conditions.

The 2023 National Electrical Code (NEC) update now requires better documentation for hazardous areas. Qualified engineers must oversee area classification and equipment selection. States will adopt these rules by 2025. Facilities must keep up with these changes to stay compliant.

Non-compliance can have severe consequences. The Deepwater Horizon oil spill in 2010 showed what can happen when safety standards are ignored. Failure to use certified equipment can lead to explosions, fires, loss of life, and huge financial losses. Certification provides assurance that the emergency Explosion Proof Telephone will work safely in dangerous conditions.

Integration with Existing Safety and Communication Systems

A new emergency Explosion Proof Telephone must fit into the facility’s current safety and communication setup. Proper integration ensures reliable performance during emergencies. Facilities should follow these best practices:

- Identify the hazardous area classification to select the right phone.

- Confirm compliance with all safety standards, including NEC, NFPA, OSHA, UL, and FM.

- Use qualified personnel for installation and grounding to maintain safety.

- Schedule regular inspections and maintenance to check for damage or wear.

- Train employees on how to use the phones and follow emergency procedures.

- Make the phone part of a larger safety plan that includes risk assessment and emergency drills.

- Address challenges like higher costs and installation complexity with expert advice and careful planning.

- Consider advanced features such as VoIP and wireless options for better integration and flexibility.

Facilities often face higher upfront costs when upgrading to certified phones. However, maintaining outdated systems can lead to hidden expenses, such as non-compliance penalties and increased safety risks. Investing in certified, integrated systems improves safety and supports long-term operational success.

🔔 Note: Avoid common mistakes like buying the cheapest device, skipping hazard assessments, or ignoring compatibility with existing systems. Proper planning and integration protect both people and assets.

Facility managers should assess current systems, confirm compliance, and select the right emergency Explosion Proof Telephone. They must schedule regular inspections, check seals and wiring, and keep detailed records. Ongoing maintenance and proper risk assessment help ensure safety, reliability, and regulatory compliance.

FAQ

What makes a telephone explosion proof?

Explosion proof telephones use strong enclosures and special seals. These features stop sparks or heat from escaping and causing explosions in hazardous areas.

How often should facilities inspect explosion proof telephones?

Facilities should inspect explosion proof telephones at least once every year. Regular checks help spot damage, worn seals, or wiring issues before they become safety risks.

Can explosion proof telephones connect to modern VoIP systems?

Many explosion proof telephones support VoIP. Facilities can integrate these phones with digital networks for better communication and faster emergency response.