Choosing the right IP Explosion Proof Telephone protects workers in hazardous locations. Safety demands devices certified for ATEX and IECEx standards. Reliable emergency Explosion Proof Telephone units resist impact, dust, and chemicals. Each ATEX Explosion Proof Telephone or mining Explosion Proof Telephone must match site-specific risks, ensuring compliance and uninterrupted operation.

IP Explosion Proof Telephone: What You Need to Know

Definition and Purpose

An IP Explosion Proof Telephone serves as a specialized communication device for hazardous industrial environments. These telephones feature enclosures that contain any internal explosion or spark, preventing ignition of flammable gases or dust in the surrounding area. Unlike standard telephones, explosion-proof models use strong, sealed enclosures made from materials such as stainless steel or aluminum alloy. This design ensures that any internal explosion remains contained, and the outside surface does not reach temperatures that could ignite hazardous materials.

- Explosion-proof telephones do not prevent sparks but contain them within the enclosure.

- The enclosures do not protect against external explosions but stop internal incidents from spreading.

- Compared to standard telephones, these devices are heavier, bulkier, and certified for use in explosive atmospheres.

- High IP ratings indicate strong protection against dust and water, which is essential for durability in harsh environments.

These telephones support reliable, hands-free communication and often include emergency features like SOS buttons and programmable keys. Their robust construction ensures they withstand vandalism, weather, and chemical exposure.

Importance in Hazardous Environments

Industrial sites such as oil refineries, chemical plants, and offshore rigs require strict safety measures. An IP Explosion Proof Telephone plays a critical role in these settings. The device prevents sparks, heat, or explosions from escaping and igniting flammable substances. Its strong, sealed enclosure contains any internal explosion, reducing the risk of a larger incident. High IP ratings, such as IP66 or IP67, ensure the phone remains dust-tight and water-resistant, protecting internal components from harsh chemicals and environmental hazards.

Tip: Regular maintenance and inspection help preserve the explosion-proof integrity of these telephones, ensuring ongoing safety and compliance.

Certification by standards like ATEX and IECEx confirms the device meets rigorous safety requirements. Reliable communication in hazardous zones helps prevent accidents and protects workers, making these telephones essential for mission-critical operations.

IP Explosion Proof Telephone Certifications and Standards

ATEX and IECEx Certifications

ATEX and IECEx certifications set the global benchmark for explosion-proof equipment. These certifications confirm that a device can safely operate in hazardous areas where explosive gases or dust may exist. Manufacturers must meet strict requirements to achieve these certifications.

Key requirements for ATEX and IECEx certified telephones include:

- Compliance with hazardous area classifications for Zone 1 and Zone 2

- Use of corrosion-resistant die-cast aluminum housing

- Ingress protection ratings of IP66 or IP67

- Certification for gas groups IIB and IIA

- Explosion protection markings such as II 2G Ex e ib [ib] mb IIC T4 Gb and II 2D Ex ib [ib] tb IIIC T135 °Db

- Ability to withstand harsh conditions like temperature extremes, humidity, dust, corrosive atmospheres, and mechanical wear

- Additional certifications and standards such as FCC, RoHS, CE, and ISO9001

- Functional features like SOS, full duplex communication, and configurable settings

Many models on the market meet these standards. The following table shows several certified options:

| Model Number | Certifications | IP Rating | Notes |

|---|---|---|---|

| JREX106-HB | ATEX, IECEx, EAC, INMETRO | IP66 | Explosion Proof Telephone |

| JREX106-A03-CB | ATEX, IECEx, EAC, INMETRO | IP66-67 | Explosion Proof IP Intercom |

| JREX106 | ATEX, IECEx, EAC, INMETRO | IP66 | Explosion Proof Telephone |

Other well-known models include:

- FHF ExResistTel IP Explosion Proof Telephone

- FHF FernTel IP Explosion Proof Telephone

- FHF Ex Howl-Call Explosion Proof Telephone

- FHF ExResistTel MB Explosion Proof Telephone

- FHF ExResistTel IP2 Explosion Proof Telephone

- FHF FernTel 3 Explosion Proof Telephone

These options provide a wide selection for industries needing certified, reliable communication in hazardous environments.

UL and Regional Standards

UL standards apply mainly in North America, while regional standards like ATEX govern Europe and other regions. Each standard uses different classification systems and certification processes. The table below compares the main differences:

| Aspect | UL Standards (North America) | Regional Standards (e.g., ATEX – Europe) |

|---|---|---|

| Geographic Applicability | Primarily North America | European Union (EU) |

| Certification Process | Third-party testing by UL, regular factory inspections | Conformity assessment, technical dossier submission, CE marking, self-certification allowed under some conditions |

| Classification System | Classes (I, II, III), Divisions (1, 2), Groups (A, B, C, D) | Zones (0, 1, 2 for gases; 20, 21, 22 for dust), Groups (I for mining, II for other industries), Categories (1, 2, 3) |

| Marking Requirements | UL logo, Class, Division, Group codes, Temperature class | Ex symbol, equipment group, category, temperature class |

| Explosion Protection Types | Includes intrinsic safety, explosion-proof, non-incendive means | Focus on equipment and protective systems meeting EU directives (ATEX 114 and 153) |

| Risk Assessment & Documentation | Required but less extensive than ATEX | Extensive risk assessments and detailed technical documentation mandatory |

| Manufacturing Implications | Emphasis on product safety and reliability, rigorous testing | More complex documentation and regulatory compliance, allows self-certification, impacts design and production processes |

| Market Requirements | Often required by regulatory authorities and insurance in US and Canada | Mandatory for equipment used in explosive atmospheres within the EU |

| Certification Renewal | Periodic audits, may require annual renewal | Valid as long as product remains unchanged and complies with latest standards |

UL certification is essential for the United States and Canada. Regulatory authorities and insurance companies in these countries often require it. ATEX certification cannot replace UL certification in North America. Manufacturers must ensure their IP explosion proof telephone meets the correct regional standard for the intended market.

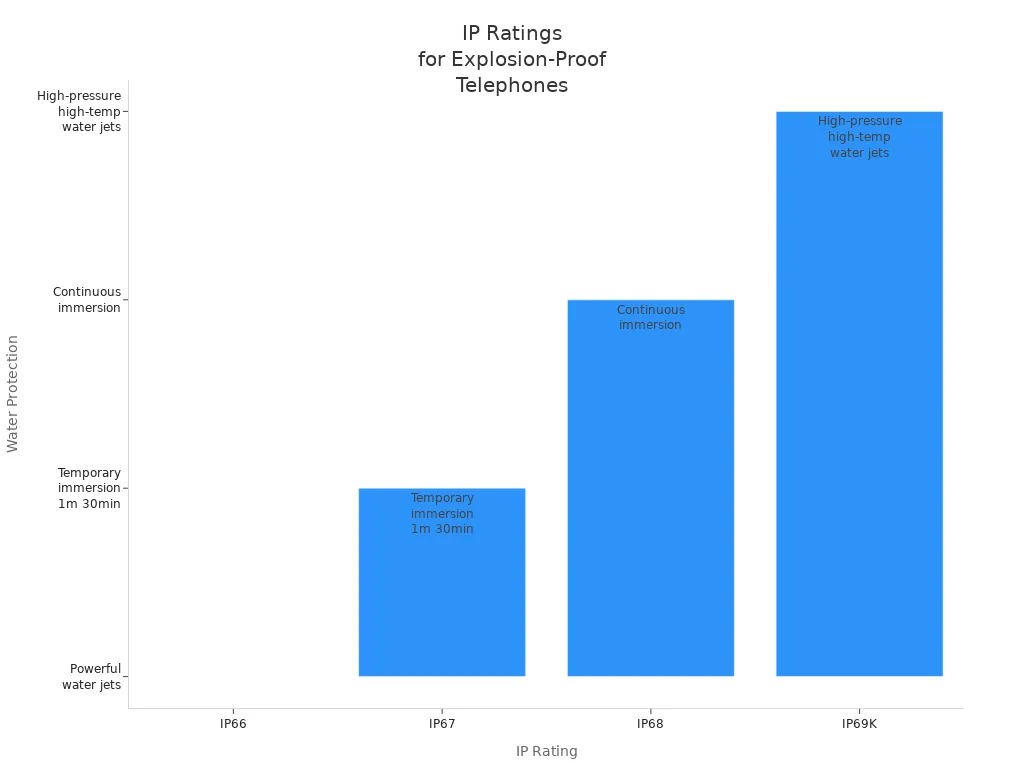

Understanding IP Ratings

IP ratings measure how well a device resists dust and water. These ratings are critical for explosion-proof telephones in hazardous environments. The first digit shows dust protection, and the second digit shows water protection. Higher numbers mean better protection. The table below explains common IP ratings:

| IP Rating | Dust Protection | Water Protection | Typical Applications |

|---|---|---|---|

| IP66 | Dust-tight | Resistant to powerful water jets | Areas exposed to dust and water spray |

| IP67 | Dust-tight | Temporary immersion up to 1m for 30 minutes | Splash-prone or wet areas |

| IP68 | Dust-tight | Continuous immersion (depth varies) | Submerged or waterline environments |

| IP69K | Dust-tight | High-pressure, high-temperature water jets | Areas requiring frequent washdowns |

Selecting a telephone with the right IP rating ensures it can handle the environmental challenges of the site. For example, IP66 and IP67 ratings protect against dust and water, which helps prevent ignition risks and keeps the device working in tough conditions. Along with certifications and construction materials, IP ratings play a key role in choosing the right telephone for hazardous areas.

Essential Features of an IP Explosion Proof Telephone

Durability and Construction Materials

Durability stands as a top priority for any device used in hazardous environments. Manufacturers select materials that can withstand physical abuse, extreme temperatures, and exposure to chemicals. Common construction materials include:

- PVC for the handset body, which offers flexibility and a comfortable grip. This material resists impact and provides a good tactile feel, making it suitable for frequent use.

- Stainless steel for enclosures, delivering superior strength and heat resistance. Stainless steel can handle harsh industrial conditions and resists corrosion.

- Polycarbonate and fiberglass for enclosures, which are lightweight and strong. These materials resist chemical corrosion but have lower tensile strength than metals.

- Sheet Molding Compound (SMC) and glassfiber reinforced polyester, which add to the device’s robustness and safety.

The rugged design of these telephones ensures they can survive accidental drops, vibration, and rough handling. Devices with an IP67 rating remain dust-tight and water-resistant, which further enhances their durability. Flameproof enclosures made from these materials can contain internal explosions, preventing the release of flames and ensuring safety in hazardous zones.

Tip: Always check the enclosure material and IP rating to ensure the telephone matches the demands of your environment.

Connectivity Options

Modern explosion proof telephones offer a range of connectivity options to suit different industrial needs. These options impact installation complexity and system integration. Key connectivity features include:

- SIP/VoIP protocol support (RFC3261), allowing seamless integration with digital communication systems.

- RJ45 Ethernet socket with an IP67 plug connector, providing secure and reliable network connections.

- Power over Ethernet (PoE) compatibility, which combines power and data in a single cable. This feature simplifies installation and reduces wiring requirements.

- External 24-48V DC power supply as an alternative to PoE, offering flexibility for sites with different power setups.

- Explosion-proof conduit entries (such as 3/4″ NPT hubs) and connectors rated for hazardous environments, which increase safety and compliance.

- Static IP or DHCP provisioning and remote management via a web interface, making network integration and maintenance easier.

The market shows a clear shift from analog to VoIP technology. While analog telephones remain valued for their simplicity, VoIP models are gaining popularity. They offer improved sound quality, cost efficiency, and better integration with digital systems. This trend reflects the growing need for advanced communication in hazardous environments.

Compatibility with Existing Systems

Compatibility with existing industrial communication systems ensures smooth operation and easy upgrades. IP explosion proof telephones support SIP/VoIP protocols, which allows them to connect directly to mainstream IP-PBX systems such as Asterisk, Cisco, Grandstream, and Yeastar. These telephones can use Power over Ethernet or standard telephone lines, making them adaptable to different network infrastructures.

Features like web GUI programming, remote software upgrades, and centralized monitoring help with management and maintenance. Integration with modern IP PBX systems enables flexible scalability and centralized control. This compatibility improves communication efficiency and safety in industries such as Oil & Gas, Chemical, Mining, and Pharmaceuticals.

Note: Always verify that the telephone supports the protocols and power options used in your facility.

Additional Safety Features

Safety features set explosion proof telephones apart from standard models. Manufacturers design these devices to meet strict safety standards and provide reliable emergency communication. Common safety features include:

- Intrinsic safety certification (IECEx, ATEX), ensuring compliance with explosion-proof requirements.

- Waterproof ratings up to IP66, protecting against dust and powerful water jets.

- High temperature approval, allowing operation in extreme thermal environments.

- Designs that limit electrical energy, preventing ignition by keeping energy levels below hazardous thresholds.

- Busy tone detection for automatic line release, improving operational safety.

- Magnetic reed hook-switches, which provide reliable and explosion-proof switching.

- Dry contact interfaces for external control automation, enabling integration with safety and control systems.

- Programmable phone book memory and selectable ringing tones, enhancing usability.

Emergency alert functions play a vital role in hazardous environments. These features include:

- Automated detection of fires, smoke, and hazardous leaks through remote sensors, which trigger immediate alarms.

- Integration with cameras and control centers for rapid assessment and coordination.

- Mass notification systems and sirens that deliver clear evacuation instructions.

- Automated personnel location and headcount systems for real-time data during emergencies.

- Fast connection speeds and automatic answering in group intercom calls, ensuring immediate communication.

- Emergency broadcast functions that play preset voice files during alarms, providing lifesaving guidance.

These features work together to ensure fast, reliable, and coordinated emergency communication, which is essential for protecting workers and assets in hazardous industrial settings.

Matching Your IP Explosion Proof Telephone to the Environment

Industry-Specific Requirements

Different industries set unique standards for safety and communication. Oil and gas, mining, and chemical processing facilities require telephones that comply with international certifications like ATEX and IECEx. These certifications confirm that devices prevent ignition sources in explosive atmospheres. Companies in these sectors also demand robust materials, such as stainless steel, to resist corrosion and damage. High ingress protection ratings, like IP66 or IP67, ensure the telephone works reliably in dusty or wet conditions. Emergency buttons and noise-cancelling features help workers communicate clearly, even in loud environments. Flexible power options, including Power over Ethernet, battery, or wired connections, support continuous operation. Regular inspections keep devices safe and reliable.

Tip: Always check for industry-required certifications before installing any communication device in hazardous areas.

Environmental Factors

Environmental conditions play a major role in device performance. IP Explosion Proof Telephones operate safely within strict temperature classifications, such as T1 to T4, to keep surface temperatures below ignition points. These telephones withstand high humidity—up to 95%—and resist dust and water with strong IP ratings. Durable housings, often made from aluminum alloy, protect against corrosion and mechanical impacts. Weatherproof keypads and sealed enclosures help maintain reliable operation in harsh settings. By meeting temperature group classifications and ingress protection standards, these telephones prevent ignition and ensure safety.

Real-World Use Cases

Many industries rely on explosion-proof telephones for daily operations. In oil refineries, workers use these devices to report emergencies and coordinate maintenance. Mining sites install them in tunnels and control rooms to ensure communication during blasting or equipment failures. Chemical plants place telephones near storage tanks and processing units, where flammable gases may escape. These real-world examples show how matching the right telephone to the environment protects workers and supports safe, efficient operations.

Step-by-Step Guide to Selecting an IP Explosion Proof Telephone

Assess Site Hazards and Needs

Every facility faces unique risks. Teams should start by conducting a risk assessment to identify hazards such as explosive gases, dust, or chemicals. They must consider the environment’s temperature, humidity, and noise levels. This process helps determine the right safety features and durability requirements for the telephone.

Verify Certifications and Compliance

Safety depends on proper certification. Buyers should check for ATEX, IECEx, or UL certifications from recognized bodies. Devices must also have suitable IP ratings for dust and moisture protection. A simple checklist can help:

- Confirm certifications match the industry and region.

- Check IP ratings for dust and water resistance.

- Review regulatory requirements and safety standards.

- Plan training for staff on device use and maintenance.

- Schedule regular inspections to maintain compliance.

Compare Features and Specifications

Not all telephones offer the same features. Teams should compare models using key criteria:

| Criteria | Details / Examples |

|---|---|

| Protection Ratings | IP66, IP68, Exna IC IIC T6 GC |

| Build Quality | Aluminum alloy, vandal-resistant hardware |

| Audio Features | Volume ≥110dB, noise-cancelling microphone |

| Network Support | SIP 2.0, PoE, LAN/WAN |

| Power Options | 220V AC, 12V DC, PoE |

| Installation | Wall-mounted, direct network connection |

| Extra Functions | Warning lights, programmable keys |

Evaluate Supplier Reputation and Support

A reliable supplier offers more than just products. Leading suppliers serve customers in over 80 countries and provide certified quality. They offer flexible order sizes, fast delivery, and clear warranty terms. Good after-sales support includes remote management tools and help with installation questions.

Make an Informed Purchase

Teams should review all findings before buying. They must match the IP Explosion Proof Telephone to site needs, confirm certifications, and choose a trusted supplier. Careful selection ensures safety, compliance, and long-term reliability.

Choosing certified and reliable explosion-proof telephones protects workers in hazardous industries.

- Always verify certifications like ATEX, IECEx, or UL.

- Assess features and match the device to the environment.

- Follow a structured buying process.

Safety and compliance must remain the top priority.

FAQ

What does “explosion proof” mean for an IP telephone?

An explosion proof telephone contains sparks or heat inside its enclosure. This design prevents ignition of flammable gases or dust in hazardous areas.

How often should workers inspect explosion proof telephones?

Workers should inspect these telephones regularly. Most sites recommend monthly checks to ensure the device remains safe and fully operational.

Can an IP explosion proof telephone connect to modern VoIP systems?

Yes. Most models support SIP or VoIP protocols. They integrate with digital PBX systems, allowing seamless communication across industrial networks.

Tip: Always check compatibility with your facility’s existing communication system before purchase.