Engineers must ensure every waterproof Tunnel telephone remains operational in harsh tunnel environments. Regular maintenance safeguards the IP Tunnel telephone, Public Tunnel telephone, and emergency Tunnel Telephone.

- Check for secure installation

- Test audio and emergency features

- Inspect for moisture or damage

Routine Inspection and Testing for Waterproof Tunnel Telephone

Inspection Frequency and Scheduling

Engineers must follow a strict inspection schedule to maintain reliable operation of every waterproof Tunnel telephone. Regular checks help identify issues before they become critical. Most teams inspect these devices at least once a month. Some high-traffic tunnels require weekly inspections.

A sample inspection schedule might look like this:

| Inspection Type | Frequency | Responsible Party |

|---|---|---|

| Visual Inspection | Weekly | Maintenance Team |

| Functional Testing | Monthly | Engineer |

| Full System Review | Quarterly | Supervisor |

Tip: Set reminders or use digital maintenance logs to track inspection dates and ensure no device is overlooked.

Visual Checks for Physical Damage

Physical damage can compromise the performance of a waterproof Tunnel telephone. Engineers should look for cracks, dents, or loose fittings on the housing. They must also check for missing screws or broken mounting brackets.

A quick visual checklist includes:

- Examine the exterior for cracks or chips.

- Check the handset and cord for wear.

- Inspect the mounting hardware for stability.

- Look for signs of tampering or vandalism.

If any damage appears, engineers should report it immediately and schedule repairs. Early detection prevents further deterioration and keeps the system safe.

Functional Testing of Call and Emergency Features

Testing the call and emergency features ensures that the waterproof Tunnel telephone works when needed. Engineers should pick up the handset and place a test call to the control room. They must verify that the call connects quickly and that both parties can hear each other clearly.

Emergency buttons or alarms require special attention. Press each emergency button and confirm that the alert reaches the correct response team. Test any built-in speaker or warning light to ensure proper function.

Note: Always document the results of each test. Consistent records help track performance trends and highlight recurring issues.

Routine inspection and testing form the foundation of effective maintenance. These steps keep every waterproof Tunnel telephone ready for use in any situation.

Cleaning and Environmental Protection of Waterproof Tunnel Telephone

Removing Dust, Dirt, and Debris

Engineers keep the waterproof Tunnel telephone clean to ensure reliable operation. Dust and dirt can block microphones, speakers, or keypads. They use a soft, dry cloth to wipe the exterior. For stubborn grime, they may use a damp cloth with mild detergent. They avoid harsh chemicals that could damage the housing or seals.

- Remove loose debris from vents and crevices.

- Check the handset and cord for buildup.

- Clean around buttons to prevent sticking.

Tip: Regular cleaning prevents dirt from entering the enclosure and extends the device’s lifespan.

Managing Moisture and Condensation

Moisture poses a serious risk to tunnel telephones. Engineers focus on sealing all gaps to stop air leaks, which can bring in water vapor. They use vapor-permeable materials and ensure proper ventilation behind the enclosure. This helps the device dry out quickly if moisture enters.

Building science research shows that limiting air leakage and using ventilation behind the enclosure surface reduces condensation. Engineers may add moisture-absorbing materials, such as desiccants, inside the enclosure. They also monitor temperature changes, since rapid shifts can cause condensation.

- Seal all joints and cable entries.

- Place desiccant packs inside the enclosure.

- Design airflow paths to promote drying.

Preventing Corrosion and Rust

Corrosion can damage metal parts and shorten the life of the telephone. Engineers select devices with an aluminum alloy die-cast body and a powder-coated, UV-stabilized polyester finish. These materials resist rust and environmental wear. Stainless steel keypads and IP66/IP67 ratings provide extra protection against water and dust.

- Choose telephones with anti-corrosive coatings.

- Inspect for signs of rust during each cleaning.

- Replace any corroded parts promptly.

Note: Devices designed for tunnels withstand heavy rain, hose jets, and even temporary immersion.

Checking Key Features of Waterproof Tunnel Telephone

Inspecting Waterproof Seals and Gaskets

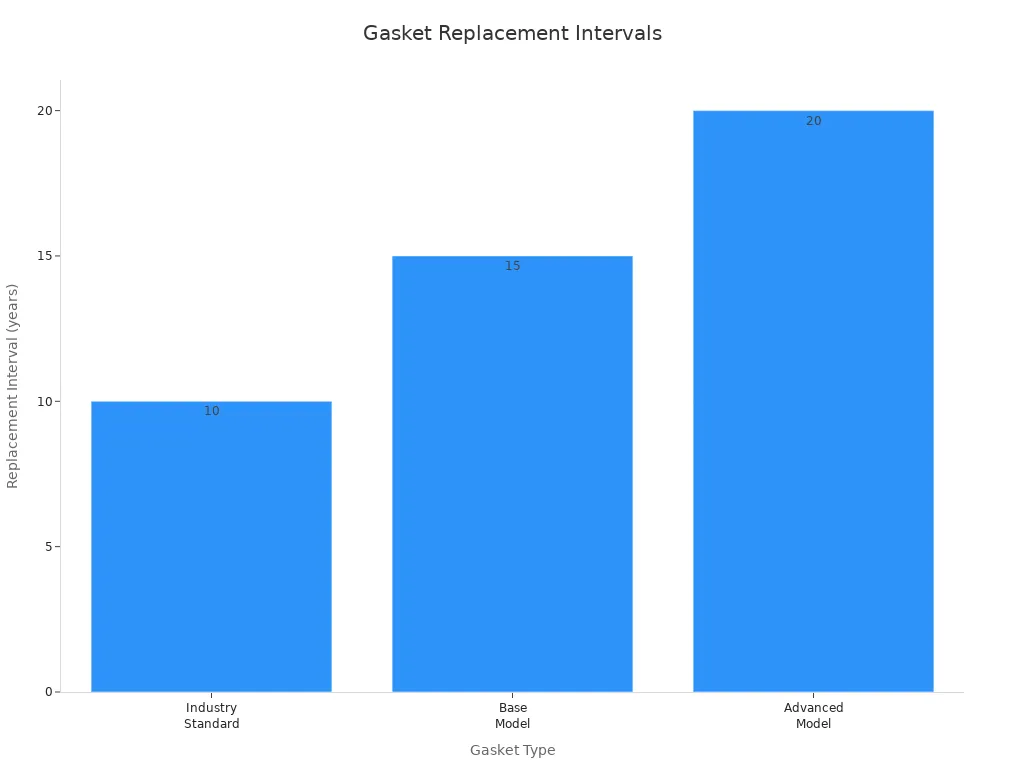

Seals and gaskets protect the internal components of a waterproof Tunnel telephone from water and dust. Engineers check these parts for cracks, brittleness, or signs of wear during every inspection. A damaged seal can allow moisture to enter, leading to equipment failure. Replacement intervals depend on the gasket type. The table below shows typical lifespans and recommended replacement schedules:

| Gasket Type | Typical Lifespan | Notes on Replacement Frequency |

|---|---|---|

| Industry Standard | 10 years | Replacement recommended every 10 years to ensure waterproof protection |

| Base Model | 15 years | Longer lifespan, replacement every 15 years |

| Advanced Model | 20+ years | Extended lifespan, replacement after 20+ years, though higher initial cost |

Engineers should always replace gaskets before the end of their lifespan to maintain full waterproof protection.

Verifying Warning Lights and Indicators

Warning lights and indicators help users locate the telephone and confirm its status. Engineers test each light during inspections. They look for dimming, flickering, or non-functioning bulbs. If a light fails, they replace it immediately. Properly working indicators ensure that users can find the telephone quickly in emergencies.

- Check all indicator lights for brightness and color.

- Test emergency warning lights for correct operation.

- Replace faulty bulbs or LEDs without delay.

Ensuring Audio Clarity and Volume

Clear audio is vital for communication in noisy tunnel environments. Engineers test the handset, speaker, and microphone for clarity and loudness. The recommended ringer volume at one meter ranges from 80 dB(A) for analog models to 90-95 dB(A) for SIP and 3G versions. External horn speakers should reach 110 dB(A) at one meter. The table below summarizes these values:

| Version Type | Ringer Volume at 1 meter | External Horn Speaker Volume at 1 meter |

|---|---|---|

| Analogue | 80 dB(A) | 110 dB(A) |

| SIP | 90-95 dB(A) | 110 dB(A) |

| 3G | 90-95 dB(A) | N/A |

The environmental noise level in tunnels often reaches 60 dB(A) or higher. The telephone’s volume must exceed this level to ensure users hear calls clearly. Engineers adjust the volume settings and replace faulty audio components as needed.

Troubleshooting Common Issues with Waterproof Tunnel Telephone

Addressing Power or Connectivity Failures

Engineers often encounter power or connectivity failures in tunnel telephones. They start by checking the power supply and ensuring all cables remain secure. If the device does not turn on, they test the voltage at the input terminals. They also inspect network cables for damage or loose connections. In some cases, water ingress can cause short circuits. Engineers look for moisture near cable entries and inside the enclosure. They dry any wet components and reseal the housing. If the problem persists, they replace damaged cables or faulty power supplies.

Tip: Always use a multimeter to confirm voltage and continuity before replacing parts.

Resolving Audio Distortion or Low Volume

Audio issues can make communication difficult in tunnels. Engineers first clean the microphone and speaker openings to remove dust or debris. They test the handset and speaker for clear sound. If distortion or low volume continues, they adjust the volume settings. They may also swap out the handset or speaker with a known working unit. Environmental noise in tunnels can mask audio signals, so engineers ensure the ringer and speaker output exceed background noise levels. Persistent problems may indicate a failing circuit board or damaged audio components.

- Clean all audio ports regularly.

- Replace worn or damaged handsets.

- Adjust volume controls as needed.

Fixing Faulty Buttons or Handsets

Buttons and handsets face heavy use and sometimes fail. Engineers inspect each button for sticking or unresponsiveness. They check the handset cord for cuts or fraying. When repairs are needed, they select replacement parts designed for harsh environments. The table below lists recommended options:

| Replacement Part | Description and Features |

|---|---|

| Stainless Steel Keypad | Weather-resistant, vandal-resistant keypad |

| Telephone Hook Switch | Rugged, mechanical switch for industrial use |

| Rugged Handset with Armored Cord | Durable handset with anti-destructive materials |

| Industrial 3G Telephone Circuit Board | Supports keypad and handset replacements |

| Analog Telephone Circuit Board with Keypad and Handset | For analog systems |

| Anti Vandal 16 Key Keypad with Zinc Alloy Buttons | Resists vandalism, ideal for public phones |

These parts help maintain reliable operation in wet and demanding tunnel conditions. Engineers always test the telephone after replacing any component to confirm proper function.

Documentation and Reporting for Waterproof Tunnel Telephone Maintenance

Keeping Accurate Maintenance Records

Engineers keep detailed records for every maintenance activity. These records include inspection dates, test results, and any repairs completed. Accurate logs help teams track the condition of each telephone over time. Many teams use digital maintenance systems to store this information. Digital records make it easy to search for past issues and plan future work. A simple table can help organize key data:

| Date | Task Performed | Engineer | Notes |

|---|---|---|---|

| 2024-04-10 | Visual Inspection | J. Smith | No issues found |

| 2024-05-05 | Audio Test | L. Brown | Replaced handset |

Keeping clear records supports compliance with safety standards and helps prevent missed maintenance.

Reporting Faults and Escalating Issues

When engineers find a problem, they report it right away. They use a standard form or digital app to describe the fault. The report includes the location, type of issue, and any immediate actions taken. If the problem affects safety or service, the engineer escalates the issue to a supervisor. Quick reporting ensures that repairs happen fast and reduces downtime.

- Describe the fault clearly.

- Include photos if possible.

- Notify the right team for urgent issues.

Scheduling Follow-Up Actions

After reporting a fault, engineers schedule follow-up actions. They set deadlines for repairs and assign tasks to the right team members. Regular follow-ups make sure no issue gets forgotten. Teams review outstanding tasks during weekly meetings. This process keeps every waterproof Tunnel telephone in top condition and ready for emergencies.

Engineers maintain safety by inspecting, cleaning, and testing each device. Timely repairs prevent failures. Proactive checks keep every waterproof Tunnel telephone reliable.

Quick-Reference Checklist:

- Inspect weekly

- Clean monthly

- Test emergency features

- Record all actions

- Report faults immediately

FAQ

How often should engineers replace waterproof gaskets?

Engineers should replace standard gaskets every 10 years. Advanced models may last 20 years. Early replacement prevents leaks and keeps the telephone protected.

What should engineers do if a tunnel telephone fails during inspection?

- Report the fault immediately.

- Tag the device as out of service.

- Schedule repairs as soon as possible.

Can engineers clean the telephone with any cleaning agent?

Engineers should use a mild detergent with a damp cloth. Harsh chemicals may damage seals or housing. Always avoid abrasive cleaners.