New IP Explosion Proof Telephone models in 2024 deliver rugged, ATEX Explosion Proof Telephone-certified designs and advanced VoIP features. Industries such as oil, mining, and chemical manufacturing now rely on these devices for reliable emergency Explosion Proof Telephone communication. Mining Explosion Proof Telephone adoption rises as regulations and industrial safety spending increase globally.

IP Explosion Proof Telephone Technology Explained

Defining IP Explosion Proof Telephone

An IP Explosion Proof Telephone serves as a specialized communication device designed for hazardous industrial environments. Manufacturers build these telephones with robust materials and advanced engineering to ensure safety and reliability. Key characteristics include:

- Corrosion-resistant aluminum alloy housing

- Complete protection against dust and moisture (IP65 or higher)

- Heavy-duty handset with a noise-canceling microphone

- Wide operating temperature range, from -40°C to +70°C

- Compliance with international safety standards such as ATEX, IECEx, CE, and FCC

- Wall, column, or structural mounting options

- Programmable weatherproof keypad and hermetically sealed switches

| Feature Category | Details |

|---|---|

| Housing Material | Corrosion resistant aluminum alloy die casting housing |

| Environmental Rating | IP65, IP66, IP67 (Ingress Protection) |

| Hazardous Area Zones | Zone 1, 2 (explosive gas atmospheres); Zone 20, 21, 22 (dust) |

| Certifications | ATEX, IECEx, CE, FCC, RoHS, ISO9001 |

| Key Features | Noise-canceling microphone, programmable keypad, hermetically sealed switches |

| Power Supply Options | Power over Ethernet (PoE), 12V DC, phone line powered |

| Operating Temperature | -40°C to +70°C |

These features make the IP Explosion Proof Telephone suitable for tunnels, marine vessels, mines, power plants, and offshore platforms.

Essential Features for Hazardous Environments

To operate safely in hazardous areas, an IP Explosion Proof Telephone must meet strict requirements. Engineers design these devices to withstand explosive gases, dust, and harsh weather. Essential features include:

- ATEX certification for Zone 1 and Zone 2 hazardous areas

- Weatherproof rating of IP66 or higher

- Impact protection (IK09 or IK10)

- Housing made from glass fiber reinforced polyester or aluminum

- Stainless steel armored handset cord for durability

- Large, glove-friendly stainless steel keypad

- Hands-free operation and locking function with PIN

- Noise suppression and dynamic microphone for clear audio

- Compatibility with PBX systems and SIP 2.0 protocol

These features ensure reliable communication even in extreme conditions such as high humidity, saltwater exposure, and mechanical strain. Industries like oil and gas, mining, and marine operations depend on these telephones to maintain safety and compliance.

IP Explosion Proof Telephone Trends in 2024

Advanced Safety Standards and Certifications

In 2024, safety standards for industrial communication devices have reached new heights. Manufacturers now design IP Explosion Proof Telephone models to meet strict international certifications. These certifications ensure devices operate safely in hazardous environments, such as oil refineries, chemical plants, and mining sites. The latest models comply with ATEX, IECEx, EAC, and INMETRO standards. These certifications confirm that the telephones can withstand explosive gases, dust, and other dangerous conditions.

| Model Number | Certifications | Ingress Protection Rating |

|---|---|---|

| JREX106-SIP | ATEX, IECEx, EAC, INMETRO | IP66 |

| JREX106 | ATEX, IECEx, EAC, INMETRO | IP66 |

| JREX106-HB | ATEX, IECEx, EAC, INMETRO | IP66 |

| JREX106-A01-FK | ATEX, IECEx, EAC, INMETRO | IP66-67 |

| JREX106-A01-CB | ATEX, IECEx, EAC, INMETRO | IP66-67 |

| JREX106-A03 | ATEX, IECEx, EAC, INMETRO | IP66-67 |

| JREX106-A03-CB | ATEX, IECEx, EAC, INMETRO | IP66-67 |

Regulatory changes in 2024, including updates to NFPA 70E and ATEX directives, require explosion-proof communication devices in hazardous zones. These regulations drive adoption in sectors like oil and gas, mining, and manufacturing. Companies now seek devices that eliminate ignition sources, use robust materials, and carry high ingress protection ratings. By meeting these requirements, organizations protect workers and comply with global safety laws.

Note: High ingress protection ratings, such as IP66 and IP67, provide resistance to dust and water, which is essential for reliable operation in challenging environments.

Smart Connectivity and VoIP Integration

Modern IP Explosion Proof Telephone models now feature advanced connectivity options. Manufacturers have integrated VoIP systems, allowing for efficient and high-quality communication. These telephones support emergency call capabilities, group calling, and call routing. They also connect with industrial systems, improving coordination and safety.

Recent advancements include the use of durable cold-rolled steel in VoIP desktop telephones. Devices like the JWAT703 offer 4G connectivity and waterproof designs, ensuring reliable communication during emergencies. Smart diagnostics and automated alerts help reduce maintenance costs and improve uptime. Many models now support remote monitoring, enabling centralized control of communications in hazardous zones.

- Integration of VoIP systems enables high-quality communication.

- Enhanced durability against dust, moisture, and corrosive elements.

- Smart diagnostics and automated alerts reduce maintenance costs.

- Digital and IP-based systems replace analog communication for greater clarity.

- Remote monitoring allows centralized control in hazardous zones.

- Modular and customizable solutions cater to diverse industrial needs.

VoIP integration brings several benefits. It reduces communication expenses, especially for long-distance calls. Scalability allows companies to add new lines and features easily. Centralized management tools help administrators control users and call routing. These features make IP Explosion Proof Telephone systems more flexible and efficient for industrial use.

Durability and Environmental Resistance

Durability remains a top priority for IP Explosion Proof Telephone manufacturers. Devices must withstand extreme temperatures, high humidity, corrosive atmospheres, and mechanical wear. Many models use reinforced protective materials, such as stainless steel or aluminum alloy, to ensure long-term reliability.

| Feature/Aspect | Description/Performance |

|---|---|

| Certification Zones | Zone 1/Zone 2 hazardous areas (flammable gases, vapors, dust) |

| Ruggedness Ratings | IP68/IP69K – resistant to water, dust, physical shock, heat, sandstorms |

| Safety Certifications | UL, ATEX, IECEx intrinsic safety certifications |

| Battery | Large capacity polymer 9000mAh battery ensuring long operation |

| Additional Functionalities | Thermal imaging, DMR digital/analog intercom, barcode scanning, strong flashlight |

| Industrial Field Feedback | Positive feedback from projects in US, Australia, EU, South Africa, Middle East |

| Material and Build | Reinforced protective materials, explosion-proof design |

| Operating Systems | Android 8.1 / Android 11 |

| Use Cases | Oil fields, gas fields, chemical industries, fire safety |

Field tests show that these telephones perform reliably in harsh conditions. They resist water, dust, physical shock, and extreme temperatures. Many models have been exported to over 50 countries, proving their effectiveness in real-world industrial projects. Companies value the rugged and waterproof design, which ensures communication remains possible even during emergencies.

User-Centric Design and Accessibility

User-centric design has become a major trend in 2024. Manufacturers focus on making IP Explosion Proof Telephone devices easy to use for all workers, including those with limited technical skills. Caller display functions allow users to see who is calling before answering. This feature helps users decide whether to take a call, which is useful in busy industrial settings.

Corded telephones remain popular because they do not emit radiation and provide reliable communication. These devices are ideal for seniors or workers who may struggle with smartphones. They do not rely on Wi-Fi or cellular reception, ensuring clear and uninterrupted communication.

| Model | Accessibility & Safety Features | Durability & Certification | Usability Enhancements | Location & Emergency Support |

|---|---|---|---|---|

| Mitel 5613 | Programmable softkeys, hands-free duplex support for standard headsets | N/A | Large backlit color display (1.8") | N/A |

| Mitel 5614 | Programmable softkeys, full duplex hands-free support for Bluetooth and standard headsets | N/A | High-resolution backlit color display (2.0") | N/A |

| Mitel 5617 | Advanced messaging, support for high precision location tracking | IP65 (shock, vibration, temperature, chemicals) | Large 2.4" TFT display, replaceable battery | 24/7 operation support |

| Mitel 5619 | Alarm support (push button, man-down, no-movement, pull-cord), programmable softkeys | IP65, ATEX/IECEx explosion safety certification | Large 2.4" TFT display, advanced messaging | High precision location tracking, emergency alarms |

Many models now include features such as man-down alerts, lone worker protection, GPS tracking, and push-to-talk. These enhancements support worker safety and make the devices suitable for emergency situations. Large, backlit displays and programmable keys improve usability, even when workers wear gloves or operate in low-light conditions.

Tip: Accessibility features like hands-free operation, emergency alarms, and location tracking help protect workers and ensure fast response during incidents.

IP Explosion Proof Telephone Model Reviews

JREX106-SIP: Features, Pros, Cons, Best Use Cases

The JREX106-SIP stands out as a reliable choice for hazardous environments. Its construction and technology meet the needs of industries like oil, gas, and chemical processing. The model offers strong protection, advanced communication features, and flexible installation options.

| Feature/Specification | Details |

|---|---|

| Housing Material | High impact glass fibre reinforced polyester (GRP) |

| Handset Material | High impact Thermoset Resin Compound |

| Mounting | Desk or wall mount |

| Ringer Volume | 90-95 dB(A) at 1 meter; up to 110 dB(A) with external horn |

| Microphone | Noise cancelling Electret microphone |

| Receiver | Hearing Aid Compatible (HAC) |

| Display | 128 x 64 pixels, heated back-lit LCD |

| Power Supply | 12V DC or PoE (IEEE802.3af/at) |

| Power Consumption | Idle: 1.5W; Active: 1.8W |

| SIP Support | SIP 2.0 (RFC3261), DTMF, SIP info, DTMF Relay |

| Supported Codecs | G.711 A/u, G.7231 high/low, G.729, G.722 |

| Echo Cancellation | G.168 standard, supports 96ms |

| Weather Resistance | IP66 to IP67 |

| Operating Temperature | -45°C to +70°C |

| Certifications | ATEX, IECEx, EAC, INMETRO |

| Additional Features | Remote programming, corrosion-resistant hardware, programmable auto hang-up timer |

Pros:

- Explosion-proof design for hazardous areas

- Durable housing resists acids, alkali, and lubricants

- Compatible with most SIP-based IP-PBX servers

- Power-over-Ethernet support

- Remote programming and web management

- Noise-canceling microphone and hearing aid compatibility

- Heated display for cold environments

- Flexible mounting options

Cons:

- Heavier than some alternatives (up to 8 kg)

- No explicit disadvantages reported in user reviews

Best Use Cases:

- Oil refineries and chemical plants

- Power generation facilities

- Mining operations

- Food processing plants

The JREX106-SIP delivers robust performance and safety for critical communication in hazardous zones.

Eaton FHF Series: Features, Pros, Cons, Best Use Cases

The Eaton FHF Series offers a strong solution for industries facing extreme environmental challenges. Its design focuses on durability and ease of use in tough conditions.

| Feature | Eaton FHF Series IP Explosion Proof Telephone Details |

|---|---|

| Environmental Suitability | Handles large temperature swings, high humidity, sea water, and dust |

| Explosion Proof Rating | Certified for hazardous industrial areas |

| Housing Material | Glass fiber reinforced polymer, resistant to acids, sea water, alkali, moisture, grease |

| Keypad | Stainless steel, UL Type 4X salt spray tested |

| Communication Protocols | Supports SIP and H323 |

| Configuration | Configurable via web browser or on-board display |

| Power Options | Power over Ethernet (PoE) or external supply |

| Additional Features | No extra enclosure needed due to IP66 / Type 4X rating |

Pros:

- Withstands harsh environments and chemical exposure

- Certified explosion-proof for industrial safety

- Stainless steel keypad for durability

- Flexible configuration options

- No need for additional protective enclosure

Cons:

- Bulkier than some modern models

- Limited smart features compared to smartphone-based solutions

Best Use Cases:

- Marine and offshore platforms

- Chemical and petrochemical plants

- Mining and heavy industry sites

The Eaton FHF Series provides reliable communication where environmental resistance is critical.

Bartec Pixavi Phone: Features, Pros, Cons, Best Use Cases

The Bartec Pixavi Phone brings smartphone technology into hazardous areas. It combines intrinsic safety with modern mobile features, making it unique among explosion-proof devices.

- Intrinsic safety certifications: ATEX Zone 1/21, IECEx Zone 1, NEC Class I Div 1/Zone 0

- Rugged design with IP68 dust and waterproof rating

- Operates in temperatures from -20°C to +60°C

- Lightweight and slim (293 grams)

- Android OS with Qualcomm Snapdragon 660, 4 GB RAM, 64 GB storage

- 5.5" Full-HD AMOLED display, glove and stylus compatible

- Programmable function button for quick access

- VoLTE, VoWiFi, dual microphones, HD voice, Bluetooth 5.0

- Dual SIM or SIM + SD card options

- Accessories: screen protector, battery tool, SIM/SD tray ejector

Pros:

- Certified for the highest levels of intrinsic safety

- Lightweight and easy to carry

- Modern Android interface and app support

- High-quality display and communication features

- Suitable for both voice and data applications

Cons:

- Higher price point than basic telephones

- May require additional training for non-smartphone users

Best Use Cases:

- Oil and gas exploration

- Chemical processing plants

- Industrial fieldwork needing mobile data and voice

The Bartec Pixavi Phone enables safe, mobile, and connected work in hazardous environments.

Comparison Table of Leading Models

| Model Name | Key Features | Certifications | IP Rating | Power Options | Weight | Best Use Case | Price (USD) |

|---|---|---|---|---|---|---|---|

| JREX106-SIP | SIP/VoIP, PoE, noise-canceling mic, heated LCD | ATEX, IECEx, EAC, INMETRO | IP66-67 | PoE, 12V DC | Up to 8 kg | Oil, gas, chemical, mining | ~$549 |

| Eaton FHF Series | SIP/H323, stainless steel keypad, web config | Explosion-proof, UL Type 4X | IP66 | PoE, external | Heavier | Marine, offshore, heavy industry | Varies |

| Bartec Pixavi Phone | Android, VoLTE, HD voice, dual SIM, IP68 | ATEX, IECEx, NEC Class I Div 1 | IP68 | Rechargeable batt. | 293 g | Mobile data/voice in hazardous zones | Premium |

🛡️ Each model addresses different needs, from rugged desk phones to advanced mobile solutions. Companies should match features to their specific environment and workflow.

How to Choose the Right IP Explosion Proof Telephone

Key Selection Criteria

Selecting the right IP Explosion Proof Telephone requires careful attention to several factors. Certification stands as the first priority. Devices must meet standards such as ATEX, IECEx, or UL to ensure safe operation in explosive environments. High ingress protection ratings, like IP65 or IP66, protect against dust and water. Construction materials should include impact-proof thermoplastic or polycarbonate with stainless steel screws for durability.

A reliable telephone must operate in extreme temperatures, from -20°C to +60°C. Noise-canceling features help maintain clear communication in loud industrial settings. Power over Ethernet simplifies installation and reduces wiring needs. Security features, such as password-protected administration and encrypted protocols, safeguard sensitive information. An illuminated keypad and display improve usability in low-light conditions.

Tip: Always check for compatibility with standard VoIP protocols, including SIP and H.323, to ensure seamless integration with existing systems.

Aligning Features with Industry Needs

Each industry faces unique challenges. Oil and gas sites need telephones that withstand corrosive atmospheres and temperature swings. Mining operations require high ringing volumes, around 95 dB at one meter, to cut through background noise. Chemical plants benefit from devices with magnetic hooks for easy handset placement and wall-mounting options for flexible installation.

A table can help match features to industry requirements:

| Industry | Essential Features |

|---|---|

| Oil & Gas | ATEX certification, corrosion resistance, PoE |

| Mining | High ringing volume, noise-canceling, rugged build |

| Chemical Plants | Wall mounting, magnetic hook, illuminated display |

Selecting the right IP Explosion Proof Telephone ensures reliable communication and safety in hazardous environments.

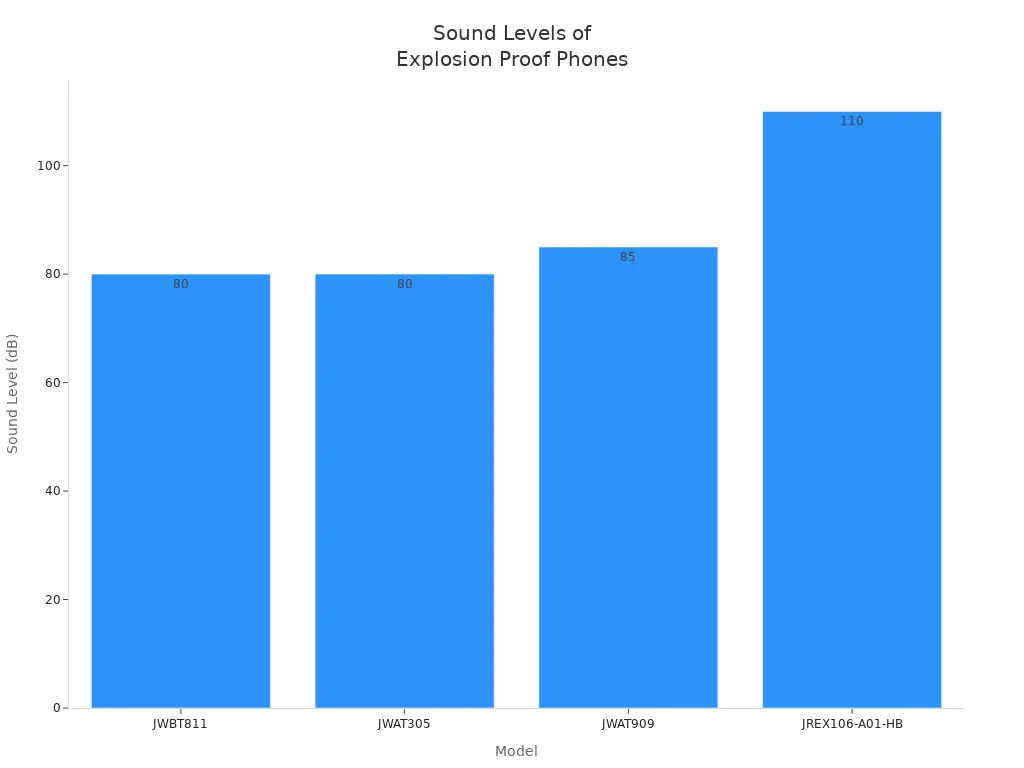

In 2024, advanced safety standards, smart connectivity, and rugged durability define industrial telephone trends. The table below highlights top models for various applications.

| Model | IP Rating | Sound Level (dB) | Features | Suitable Applications |

|---|---|---|---|---|

| JWBT811 | IP66/IP67 | 80 | Loudspeaker, beacon, PoE | Harsh, explosion-proof environments |

| JWAT305 | IP66/IP67 | 80+ | Analog, CE/FCC certified | Outdoor industrial use |

| JWAT909 | IP66 | 85 | Ethernet LAN/WAN, loudspeaker | Public, weatherproof locations |

| JREX106-HB | IP66 | N/A | Explosion-proof, beacon, PoE | High-risk industrial sites |

| JREX106-A01-HB | IP65 | 110 | Explosion-proof, beacon | Hazardous zones |

| KNSP-15MT K2 | IP66 | 100-120 | Rugged, VoIP/analog support | Ships, docks, drilling platforms |

Users should select models based on environment, sound level, and special features. Prioritizing safety, clear communication, and ease of use ensures reliable performance in every industrial setting.

FAQ

What does "IP rating" mean for explosion proof telephones?

The IP rating shows how well a telephone resists dust and water. Higher numbers mean better protection in tough environments.

Can workers use explosion proof telephones with gloves?

Yes. Most models have large, glove-friendly keypads. Workers can press buttons easily, even with thick safety gloves.

How often should companies inspect explosion proof telephones?

Companies should inspect these telephones every month. Regular checks help ensure reliable operation and safety compliance.

Tip: Schedule inspections during routine safety checks to avoid missed maintenance.