A factory worker can install an analog Industrial Telephone with little hassle. Many choose a الهاتف الصناعي for tough environments. Some prefer a Marine Industrial Telephone or a waterproof Industrial Telephone when moisture is a concern. > Reliable communication starts with the right device and a straightforward setup.

Why Installing an Analog Industrial Telephone Is Simple

Basic Wiring Requirements

Installing an analog Industrial Telephone does not require advanced skills. The process uses simple copper wires that carry voice signals. Workers only need to connect the telephone to the existing wiring. Most analog phones use a pair of wires called Tip and Ring. These wires transmit sound without needing digital networks or internet connections.

Tip: Always check the wiring with a volt-ohm meter to avoid cross-wiring and ensure a clear signal.

Sometimes, factories face challenges like identifying the right wires or working around old equipment. Safety gear helps protect workers from sharp edges or heavy objects. With careful steps, most people can handle the wiring without trouble.

Compatibility with Factory Infrastructure

Analog Industrial Telephones work well in many factory settings. They fit into places like warehouses, construction sites, and noisy production floors. These phones do not need modern digital systems or internet access.

- They connect easily to older phone lines.

- They keep working during power outages.

- They support other devices like fax machines.

This makes them a smart choice for factories that want reliable communication without upgrading their whole system.

Minimal Tools and Equipment Needed

Workers do not need special tools to install an analog Industrial Telephone. Basic hand tools, such as screwdrivers and wire strippers, usually get the job done.

- No need for routers or modems.

- No complex software to install.

- Simple testing tools, like a lineman’s buttset, help check the line.

Because the setup is so simple, teams save time and money. They can focus on keeping the factory running smoothly.

How to Install and Maintain an Analog Industrial Telephone

Choosing the Right Location

Selecting the best spot for an analog Industrial Telephone makes a big difference in daily factory life. Workers should place the phone where everyone can reach it quickly, especially during emergencies. High-traffic areas, near entrances, or close to workstations often work well. The phone should stay away from heavy machinery that creates loud noise or vibration. Moisture and dust can damage the phone, so a dry, clean wall is best.

Tip: Mark the chosen location with a label or sign so everyone knows where to find the phone.

Mounting and Securing the Telephone

Mounting the analog Industrial Telephone keeps it safe and easy to use. Workers usually use a drill and screws to attach the phone to a wall or sturdy post. The phone should sit at a height that most people can reach without stretching or bending.

- Use wall anchors if the wall is not solid.

- Secure all cables with clips or ties to prevent tripping.

- Double-check that the phone does not wobble or move.

A well-mounted phone lasts longer and stays reliable, even in busy factory settings.

Connecting Power and Telephone Lines

Connecting the phone lines and power is a step-by-step process. Here is a simple guide:

- Plan the layout and decide how many phones and lines the factory needs.

- Set up the Main Distribution Frame (MDF) as the main hub for all telephone lines.

- Connect the incoming lines from the Network Interface Device (NID) to the MDF.

- Run cables from the MDF to other parts of the building if needed.

- Install junction boxes and telephone jacks (usually RJ11) at each phone location.

- Plug the analog Industrial Telephone into the jack.

- Test the phone for a dial tone and clear sound.

- Always turn off power when working near wires and use insulated tools.

Workers need a few basic tools for this job, such as wire cutters, screwdrivers, a drill, and a cable tester. The NID acts as the bridge between the phone company and the factory’s own wiring. Junction boxes help keep wires neat and safe, while telephone jacks make it easy to connect each phone.

Safety and Compliance Considerations

Safety comes first when installing any equipment in a factory. Workers should use only the cables and power adapters recommended by the manufacturer. Electrical grounding is important to prevent shocks or fires.

- All wiring must have strong insulation and be protected from damage.

- Wires should stay dry and supported, especially if mounted on walls.

- Only trained staff or those supervised by an experienced person should handle installation.

- Every installation needs proper paperwork, including a signed statement from the supervisor.

The analog Industrial Telephone must meet local building and electrical codes. In the United States, the National Electrical Code Article 800 covers telephone wiring. The phone should also meet FCC Part 68 standards for safety and hearing aid compatibility.

Note: Repairs should only be done by authorized technicians to keep the system safe and up to code.

Routine Maintenance and Troubleshooting

Regular checks help keep the analog Industrial Telephone working well. Workers should look for loose wires, dust, or signs of wear. Cleaning the phone and checking the line for a clear dial tone can prevent problems.

If issues do come up, here are some common ones and how to check them:

| مشكلة | Common Causes / Checks |

|---|---|

| Dead Line | Check all connections, make sure the phone is plugged in, and test the line for power. |

| Bad Audio | Inspect cables for damage and make sure the phone is not too close to noisy machines. |

| Registration Failures | Make sure the phone is set up with the correct information and try restarting it. |

| Calls Dropping | Look for updates to the phone’s software or try restarting the phone. |

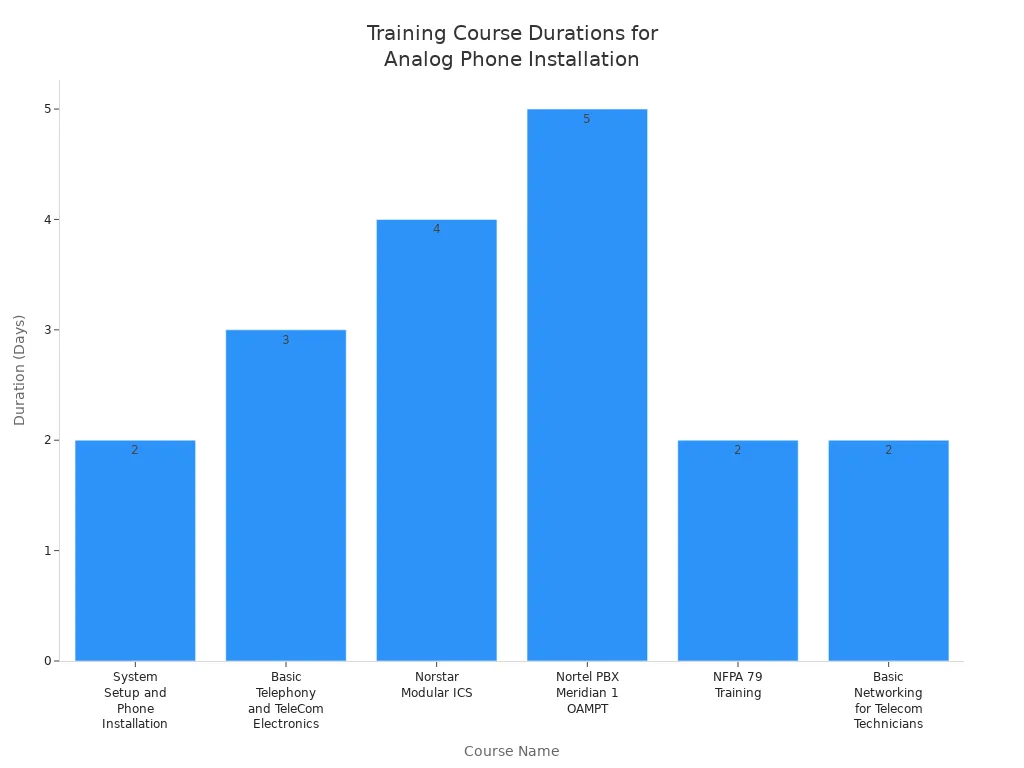

Training helps workers handle installation and maintenance with confidence. Many companies offer short courses that cover setup, wiring, safety, and troubleshooting. Some courses last just two days, while others go up to five days for more advanced topics.

Callout: A little training goes a long way. Even a basic course can help staff avoid mistakes and keep the phone system running smoothly.

Installing an analog Industrial Telephone in a factory feels simple when workers follow the right steps. They just need to pay attention to safety and check the phone often. Most teams handle small problems fast. > Reliable communication helps everyone stay connected and safe on the job.

FAQ

How long does it take to install an analog industrial telephone?

Most workers finish the job in less than one hour. The process goes faster with the right tools and a clear plan.

Can factory staff fix common telephone problems themselves?

Yes, they can handle most issues. Simple checks like tightening wires or cleaning the phone often solve the problem.

Does an analog industrial telephone need internet to work?

No, it does not need internet. The phone uses copper wires and works even if the internet goes down.

Tip: Always keep a basic tool kit nearby for quick fixes.