Epi wafers play a critical role in modern electronics. These wafers are designed to deliver exceptional electrical properties that improve device performance. By using epi wafers, you gain access to superior crystal structures with fewer defects, resulting in better conductivity and reliability. An الرقاقة الفوقية ensures precise control over material properties, making it ideal for high-performance applications. For advanced technologies, an الويفر السيليكون الفوقي provides the foundation for energy-efficient and durable devices.

المداخل الرئيسية

- Epi wafers have better crystal quality, lowering defects and boosting reliability.

- They improve how electricity flows, making signals move faster in devices.

- Epi wafers help control material properties, making devices work their best.

- These wafers are good for making many devices cheaply and with high quality.

- Using epi wafers saves money over time by cutting failures and saving energy.

Using Epi Wafers: Definition and Basics

What Are Epi Wafers?

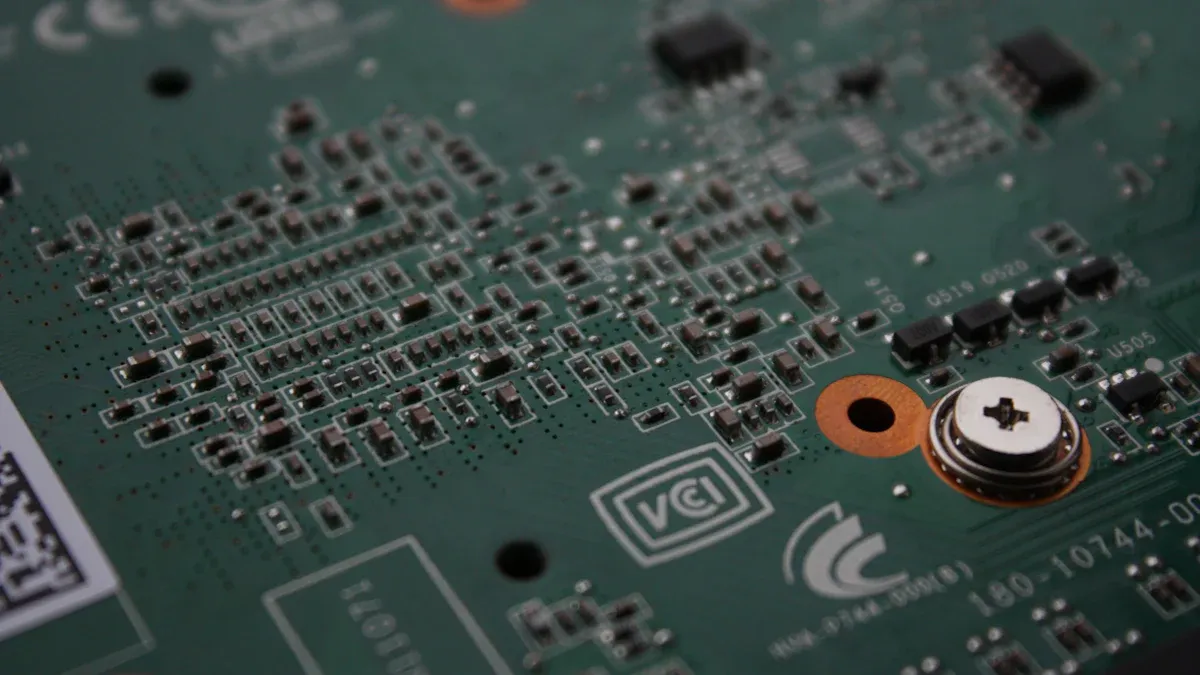

Epi wafers, short for epitaxial wafers, are specialized semiconductor materials. These wafers have a thin, high-quality crystalline layer grown on top of a substrate. This layer is engineered to have specific electrical properties, making it ideal for advanced electronic devices. You can think of an epi wafer as a foundation that ensures precision and performance in semiconductor applications. By using epi wafers, you gain better control over the material’s structure and properties, which is crucial for modern technology.

How Are Epi Wafers Manufactured?

The manufacturing process of epi wafers involves epitaxy, a technique where a crystalline layer is deposited onto a substrate. This process uses chemical vapor deposition (CVD) or molecular beam epitaxy (MBE). During epitaxy, you can control factors like temperature, gas flow, and doping levels to achieve the desired properties. The result is a wafer with a defect-free surface and enhanced electrical characteristics. Using epi wafers ensures that the devices built on them perform reliably and efficiently.

Why Are Epi Wafers Important in Semiconductor Devices?

Epi wafers play a vital role in semiconductor devices. They provide a platform with superior crystal quality, which reduces defects and improves conductivity. This makes them essential for high-performance applications like power electronics, LEDs, and high-frequency devices. When you use epi wafers, you ensure that your devices operate with greater efficiency and reliability. Their ability to support precise doping and customization further enhances their importance in the semiconductor industry.

Key Advantages of Using Epi Wafers

Superior Crystal Quality and Reduced Defects

When you use epi wafers, you gain access to materials with exceptional crystal quality. The epitaxial layer grown on the substrate minimizes imperfections, ensuring a smooth and defect-free surface. This reduction in defects directly improves the reliability of semiconductor devices. Defects in traditional substrates can lead to electrical inconsistencies, but epi wafers eliminate these issues.

Tip: Superior crystal quality is essential for applications requiring high precision, such as power electronics and optoelectronics.

Epi wafers also enhance the lifespan of devices. Fewer defects mean less risk of failure during operation. This makes them ideal for industries where durability and performance are critical.

Enhanced Electrical Conductivity and Carrier Mobility

Epi wafers offer improved electrical conductivity, which is vital for efficient device operation. The epitaxial layer allows electrons and holes to move freely, increasing carrier mobility. Higher mobility means faster signal transmission and better performance in high-frequency applications.

You can rely on epi wafers for devices that demand rapid response times, such as communication systems and advanced computing. Their ability to support high-speed operations makes them indispensable in modern technology.

| Feature | Benefit |

|---|---|

| High carrier mobility | Faster signal transmission |

| Improved conductivity | Enhanced energy efficiency |

Better Control Over Doping Concentrations

Using epi wafers gives you precise control over doping concentrations. Doping involves adding impurities to the semiconductor material to modify its electrical properties. The epitaxial process allows you to customize the doping levels in the crystalline layer, ensuring optimal performance for specific applications.

ملاحظة: Precise doping control is crucial for creating devices with consistent and predictable behavior.

This level of control is especially important in industries like optoelectronics and power electronics. You can tailor the material properties to meet the demands of LEDs, lasers, and high-power devices. Epi wafers ensure that your devices perform reliably under varying conditions.

Scalability and Cost Efficiency for High-Volume Production

Epi wafers are not only about performance; they also excel in scalability and cost efficiency. When you consider high-volume production, these wafers provide a clear advantage. Their manufacturing process allows for consistent quality across large batches, which is essential for industries that demand precision and reliability.

One of the key benefits of using epi wafers is their ability to support mass production without compromising on quality. The epitaxial growth process ensures uniformity in the crystalline layer, even when producing thousands of wafers. This consistency reduces the risk of defects, saving you time and resources during device fabrication.

Tip: Consistency in production helps you avoid costly rework and ensures faster time-to-market for your products.

Epi wafers also contribute to cost efficiency by optimizing material usage. The epitaxial layer can be tailored to specific thicknesses and doping levels, minimizing waste. This customization reduces the need for additional processing steps, which lowers overall production costs. For high-power and high-frequency applications, this efficiency becomes even more critical.

| Feature | Benefit |

|---|---|

| Uniform crystalline layer | Reduced defects in large-scale production |

| Tailored material properties | Lower material waste and processing costs |

Another factor that enhances scalability is the compatibility of epi wafers with existing semiconductor manufacturing technologies. You can integrate them seamlessly into your production lines, avoiding the need for expensive equipment upgrades. This compatibility ensures that you can scale up production without significant capital investment.

ملاحظة: By using epi wafers, you can achieve a balance between performance and cost, making them ideal for industries like consumer electronics and automotive.

In high-volume production, every detail matters. Epi wafers provide the reliability and efficiency you need to meet market demands while keeping costs under control. Their scalability ensures that your devices maintain high performance, even as production scales up.

Comparing Epi Wafers to Non-Epitaxial Substrates

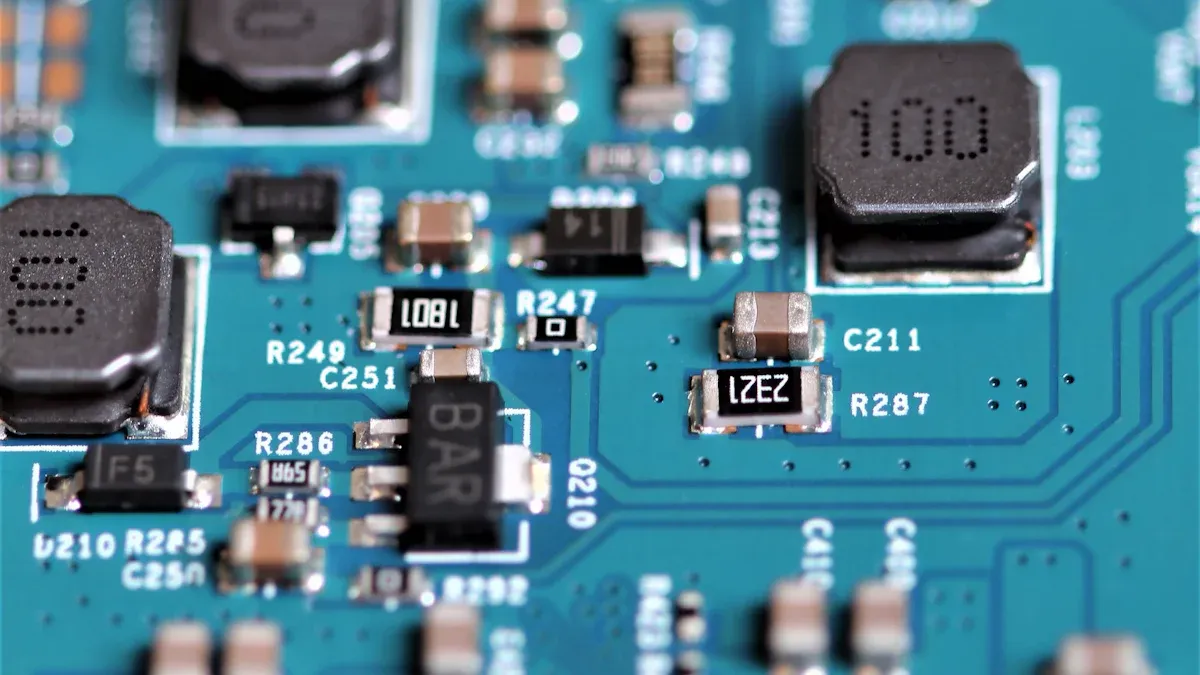

Differences in Electrical Properties and Defect Density

Epi wafers and non-epitaxial substrates differ significantly in their electrical properties and defect density. Epi wafers have a high-quality crystalline layer that minimizes defects. This layer ensures better conductivity and more reliable device performance. Non-epitaxial substrates, on the other hand, often have higher defect densities. These defects can disrupt electrical flow, leading to inconsistent performance.

When you use epi wafers, you gain precise control over the material’s structure. This control allows for better carrier mobility and reduced energy loss. Non-epitaxial substrates lack this level of precision, making them less suitable for high-performance applications.

Tip: If your application demands high efficiency and reliability, epi wafers are the superior choice.

Performance Benefits in High-Power Applications

Epi wafers excel in high-power applications due to their superior electrical properties. The reduced defect density ensures that devices can handle higher voltages and currents without failure. This makes them ideal for power electronics, such as inverters and converters.

Non-epitaxial substrates struggle in these scenarios. Their higher defect density increases the risk of breakdown under high-power conditions. Epi wafers, with their enhanced conductivity, allow for efficient energy transfer. This efficiency reduces heat generation, improving the device’s lifespan.

| Feature | Epi Wafers | Non-Epitaxial Substrates |

|---|---|---|

| Defect Density | Low | High |

| High-Power Performance | ممتاز | Limited |

Cost vs. Long-Term Value Analysis

While epi wafers may have a higher initial cost, their القيمة الطويلة الأجل outweighs the expense. Their superior quality reduces the likelihood of device failure, saving you money on repairs and replacements. Non-epitaxial substrates might seem cost-effective upfront, but their higher defect rates can lead to increased maintenance costs.

Epi wafers also improve energy efficiency, lowering operational costs over time. Their durability ensures that devices last longer, providing better returns on your investment.

ملاحظة: Investing in epi wafers ensures long-term reliability and cost savings, making them a smart choice for high-performance applications.

Applications of Using Epi Wafers in Devices

Power Electronics for Energy Efficiency

أجهزة إلكترونية للطاقة rely on efficient energy conversion and management. Using epi wafers allows you to achieve this efficiency by providing superior electrical properties. These wafers reduce energy loss during operation, making them ideal for devices like inverters, converters, and motor drives.

Epi wafers also enable devices to handle higher voltages and currents without overheating. This makes them essential for renewable energy systems, such as solar inverters and wind turbine controllers. By minimizing energy waste, they contribute to greener and more sustainable technologies.

Tip: If you’re designing power electronics, consider epi wafers to improve energy efficiency and device reliability.

Optoelectronics, Including LEDs and Lasers

Optoelectronic devices, such as LEDs and lasers, require precise material properties for optimal performance. Epi wafers provide the high-quality crystalline layers needed for efficient light emission. When you use epi wafers, you ensure that your LEDs produce brighter light with lower energy consumption.

Lasers also benefit from the superior crystal quality of epi wafers. These wafers allow for precise wavelength control, which is critical in applications like fiber-optic communication and medical devices. The ability to customize doping levels further enhances their performance in optoelectronics.

| الجهاز | Benefit of Epi Wafers |

|---|---|

| LEDs | Brighter light, energy efficiency |

| الليزر | Precise wavelength control |

High-Frequency and High-Power Semiconductor Devices

High-frequency and high-power devices demand materials with excellent electrical conductivity and low defect density. Epi wafers meet these requirements, making them indispensable in applications like RF amplifiers, radar systems, and 5G communication devices.

Using epi wafers ensures that your devices can operate at high frequencies without signal degradation. Their ability to handle high power levels also reduces the risk of failure, even under demanding conditions. This makes them a preferred choice for industries like telecommunications and aerospace.

ملاحظة: For high-frequency and high-power applications, epi wafers provide unmatched performance and reliability.

Epi wafers form the backbone of modern semiconductor devices. Their superior crystal quality and enhanced conductivity ensure reliable performance in high-demand applications. You benefit from their scalability, which supports efficient production for industries like power electronics and optoelectronics.

ملاحظة: As technology advances, epi wafers will drive innovation in energy-efficient and compact designs. Their unmatched electrical properties make them indispensable for creating devices that meet the challenges of tomorrow.

By choosing epi wafers, you invest in materials that deliver precision, durability, and long-term value.

FAQ

What makes epi wafers different from standard wafers?

Epi wafers have a high-quality crystalline layer grown on a substrate. This layer reduces defects and improves electrical properties. Standard wafers lack this precision, making epi wafers superior for high-performance applications.

Can epi wafers improve energy efficiency in devices?

Yes, epi wafers enhance كفاءة الطاقة by reducing energy loss during operation. Their superior conductivity and low defect density make them ideal for power electronics and renewable energy systems.

Are epi wafers suitable for high-frequency applications?

Absolutely! Epi wafers provide excellent carrier mobility and conductivity. These properties ensure reliable performance in high-frequency devices like 5G communication systems and radar technologies.

How do epi wafers contribute to cost efficiency?

Epi wafers support consistent quality in large-scale production. Their precise material control reduces waste and minimizes additional processing steps, lowering overall manufacturing costs.

Why are epi wafers essential for optoelectronic devices?

Epi wafers ensure precise material properties for efficient light emission. They improve brightness and energy efficiency in LEDs and enable wavelength control in lasers, making them indispensable for optoelectronics.

الاتصال بنا للحصول على معلومات أفضل

By:semicera

Address : No. 1958 Jiangnan Road, Ningbo High tech Zone, Zhejiang Province, 315201, China

E-mail : sales01@semi-cera.com

E-mail : sales05@semi-cera.com

Tel: 86-0574-8650 3783

Phone : 86-13373889683

Skype : xianeryeah@outlook.com

Whatapp : 86-13373889683

Xing:https://www.xing.com/discover/your-posts

Pinterest:https://www.pinterest.com/Semicera/

Facebook:https://www.facebook.com/profile.php?id=61575124466678

Youtube:https://www.youtube.com/@Semicera