Selecting the right EPI Susceptor material is crucial for high-purity applications. Each material impacts performance, durability, and contamination levels. Boron Nitride and Graphite stand out as top contenders due to their unique properties. Understanding their strengths and limitations helps you make an informed decision for achieving optimal results in demanding environments.

Key Takeaways

- Boron Nitride works well for clean uses because it doesn’t react with chemicals, reducing contamination.

- Graphite costs less but might need protection to stay pure in delicate settings.

- At very high heat over 2,000°C, Boron Nitride stays stable and works better.

Key Properties of Graphite

Thermal Conductivity

Graphite excels in thermal conductivity, making it a popular choice for heat-intensive applications. Its layered structure allows heat to flow efficiently, ensuring even temperature distribution. When you use graphite in an EPI Susceptor, it helps maintain consistent thermal performance, which is critical for processes like semiconductor manufacturing. This property reduces the risk of thermal stress and enhances the overall reliability of your system.

Mechanical Strength

Graphite offers impressive mechanical strength, especially under high-temperature conditions. Its ability to withstand thermal expansion and contraction without cracking makes it a durable option. You can rely on graphite to maintain its structural integrity even in demanding environments. However, it is worth noting that graphite is brittle and may require careful handling to avoid damage during installation or operation.

Chemical Reactivity

Graphite demonstrates moderate chemical reactivity. While it resists many chemicals, it can oxidize at high temperatures in the presence of oxygen. This limitation means you may need to use protective coatings or operate in controlled atmospheres to prevent degradation. For high-purity applications, such as those involving an EPI Susceptor, this reactivity could pose a challenge if not properly managed.

Cost Factors

Graphite is generally more affordable than many alternative materials, including boron nitride. Its widespread availability and ease of machining contribute to its cost-effectiveness. If you are working within a tight budget, graphite can be an attractive option. However, you should also consider the potential costs of maintenance and protective measures required to address its chemical reactivity and brittleness.

Key Properties of Boron Nitride

Thermal Stability

Boron Nitride stands out for its exceptional thermal stability. You can rely on it to perform consistently at temperatures exceeding 2,000°C. Unlike graphite, Boron Nitride resists thermal expansion and contraction, which minimizes the risk of cracking or warping. This stability makes it ideal for high-purity applications where precise temperature control is critical. For processes involving an EPI Susceptor, Boron Nitride ensures reliable performance even under extreme heat conditions.

Tipp: If your application involves prolonged exposure to high temperatures, Boron Nitride offers a dependable solution that reduces maintenance needs.

Chemical Inertness

Boron Nitride exhibits remarkable chemical inertness. It resists reactions with acids, alkalis, and most other chemicals, even at elevated temperatures. This property ensures that your system remains free from contamination, which is essential for high-purity applications. When you use Boron Nitride in an EPI Susceptor, you can maintain the integrity of your process without worrying about chemical degradation or unwanted reactions.

- Advantages of Chemical Inertness:

- Prevents contamination in sensitive environments.

- Reduces the need for protective coatings or controlled atmospheres.

- Enhances the longevity of the material.

Electrical Insulation

Boron Nitride is an excellent electrical insulator. Its high dielectric strength makes it suitable for applications where electrical conductivity must be minimized. You can use Boron Nitride to isolate electrical components while maintaining thermal efficiency. This property is particularly valuable in semiconductor manufacturing, where electrical insulation plays a crucial role in ensuring product quality.

Note: Boron Nitride’s combination of thermal stability and electrical insulation makes it a versatile choice for industries requiring precision and reliability.

Cost Considerations

Boron Nitride is more expensive than graphite. Its higher cost reflects its superior properties, including thermal stability, chemical inertness, and electrical insulation. While the upfront investment may seem significant, you should consider the long-term benefits. Boron Nitride reduces maintenance costs, minimizes contamination risks, and extends the lifespan of your equipment. For high-purity applications, the value it provides often outweighs the initial expense.

Callout: If your budget allows, investing in Boron Nitride can save you money in the long run by reducing downtime and improving process efficiency.

Comparison of EPI Susceptor Materials

Purity Levels

When purity is your top priority, Boron Nitride outshines Graphite. Its chemical inertness ensures minimal contamination, making it ideal for high-purity applications. Graphite, while effective in many scenarios, can introduce impurities due to its moderate chemical reactivity. This difference becomes critical in processes like semiconductor manufacturing, where even trace contaminants can compromise product quality.

Tipp: Choose Boron Nitride for applications requiring ultra-high purity to maintain the integrity of your process.

Resistance to Contamination

Boron Nitride offers superior resistance to contamination. Its non-reactive nature prevents chemical interactions that could degrade your system or introduce impurities. Graphite, on the other hand, requires protective coatings or controlled environments to mitigate its susceptibility to oxidation. If your application involves sensitive materials or environments, Boron Nitride provides a cleaner and more reliable solution.

- Key Takeaways:

- Boron Nitride minimizes contamination risks.

- Graphite may need additional measures to maintain purity.

Performance at High Temperatures

Both materials perform well at elevated temperatures, but Boron Nitride takes the lead in extreme conditions. It maintains stability beyond 2,000°C, ensuring consistent performance without cracking or warping. Graphite, while thermally conductive, faces challenges like oxidation at high temperatures. For applications involving prolonged heat exposure, Boron Nitride delivers unmatched reliability.

Note: If your EPI Susceptor operates in high-temperature environments, Boron Nitride reduces maintenance and enhances durability.

Recommendations for High-Purity Applications

Semiconductor Manufacturing

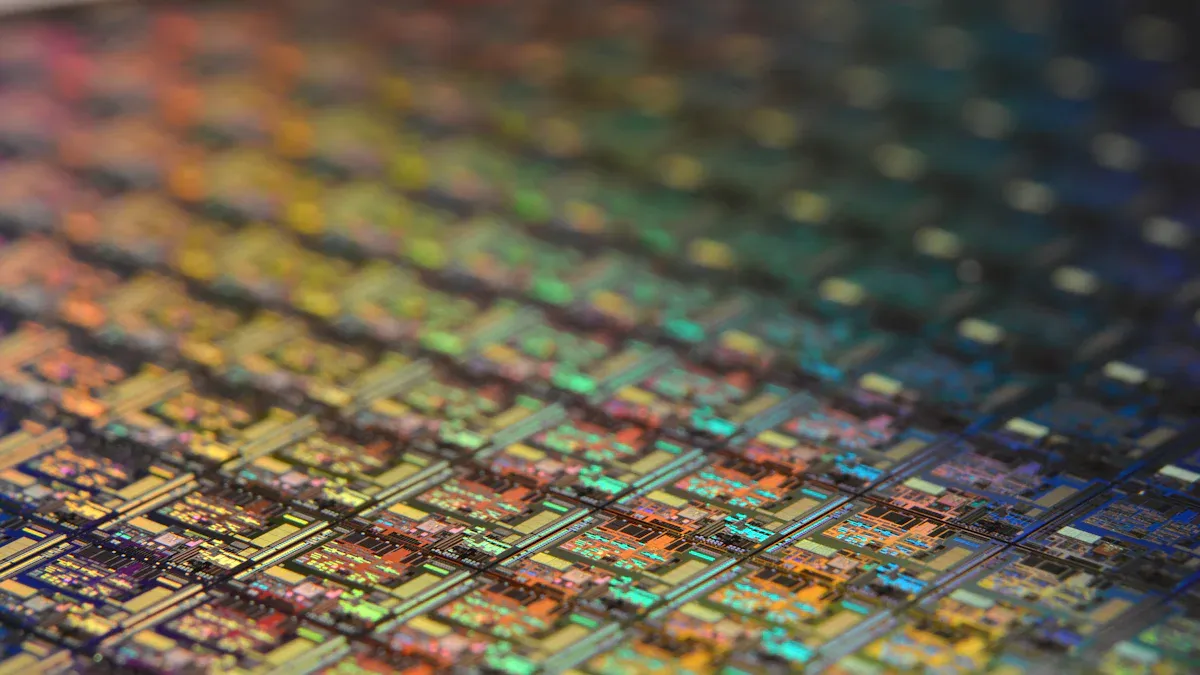

In semiconductor manufacturing, precision and purity are critical. You need materials that can handle extreme temperatures while maintaining a clean environment. Boron Nitride is an excellent choice for this industry. Its chemical inertness ensures that no contaminants interfere with the delicate processes involved in creating semiconductor wafers. Additionally, its thermal stability allows it to perform consistently during high-temperature operations.

Graphite, while cost-effective, may introduce impurities due to its moderate chemical reactivity. If you choose graphite, you must implement protective measures like coatings or controlled atmospheres to maintain purity. However, for ultra-high-purity applications, Boron Nitride provides a more reliable solution.

Tipp: For semiconductor manufacturing, prioritize materials that minimize contamination risks and ensure consistent performance under heat.

LED Production

The production of LEDs requires materials that can withstand high temperatures and maintain electrical insulation. Boron Nitride excels in this area. Its combination of thermal stability and electrical insulation makes it ideal for processes where precision is key. You can rely on Boron Nitride to support the growth of high-quality LED crystals without introducing impurities.

Graphite, with its excellent thermal conductivity, can also be used in LED production. However, its electrical conductivity may pose challenges in certain applications. If you decide to use graphite, ensure that it aligns with the specific requirements of your process.

- Key Considerations for LED Production:

- Use Boron Nitride for applications requiring electrical insulation.

- Consider graphite for cost-sensitive projects where thermal conductivity is a priority.

Other Specialized Processes

Many specialized processes, such as chemical vapor deposition (CVD) and epitaxial growth, demand materials with unique properties. The EPI Susceptor plays a crucial role in these processes by providing a stable platform for material deposition. Boron Nitride’s chemical inertness and thermal stability make it a top choice for these applications. It ensures that your system remains free from contamination, even under extreme conditions.

Graphite can also be used in specialized processes, especially when cost is a concern. However, you must account for its susceptibility to oxidation and potential for introducing impurities. For processes requiring ultra-high purity, Boron Nitride offers unmatched reliability and performance.

Note: Evaluate the specific needs of your process to determine whether Boron Nitride or Graphite is the better fit. Consider factors like purity, temperature, and cost.

Boron Nitride offers unmatched purity and stability, while Graphite excels in cost-effectiveness and thermal conductivity. You should choose Boron Nitride for ultra-high-purity applications like semiconductor manufacturing. Graphite works well for budget-sensitive projects.

Tipp: Align material properties with your process needs to ensure optimal performance and long-term reliability.

FAQ

What factors should you prioritize when selecting an EPI susceptor material?

Focus on thermal stability, chemical inertness, and purity. Match the material’s properties to your process requirements for optimal performance and minimal contamination risks.

Is Boron Nitride always better than Graphite for high-purity applications?

Not always. Boron Nitride excels in ultra-high-purity environments, but Graphite works well for cost-sensitive projects where moderate purity and high thermal conductivity suffice.

How can you reduce oxidation risks when using Graphite?

Operate in controlled atmospheres or apply protective coatings. These measures help prevent oxidation and maintain the material’s integrity during high-temperature processes.

Tipp: Always evaluate your process needs before choosing between Boron Nitride and Graphite.