Extreme environments demand solutions that can withstand corrosion, abrasion, and high temperatures. TAC Coating offers a transformative way to protect assets in the oil and gas industry. You can rely on its advanced properties to extend equipment life, reduce maintenance, and ensure reliability under the harshest conditions.

Key Takeaways

- TAC Coating keeps equipment safe from rust, wear, and heat. It helps equipment last longer and need fewer repairs.

- Putting TAC Coating on tools in oil and gas work saves money. It lowers repair costs and cuts down on work delays.

- TAC Coating is good for the environment. It reduces trash and stops the need to replace equipment often.

The Technology Behind TAC Coating

Key Features and Properties

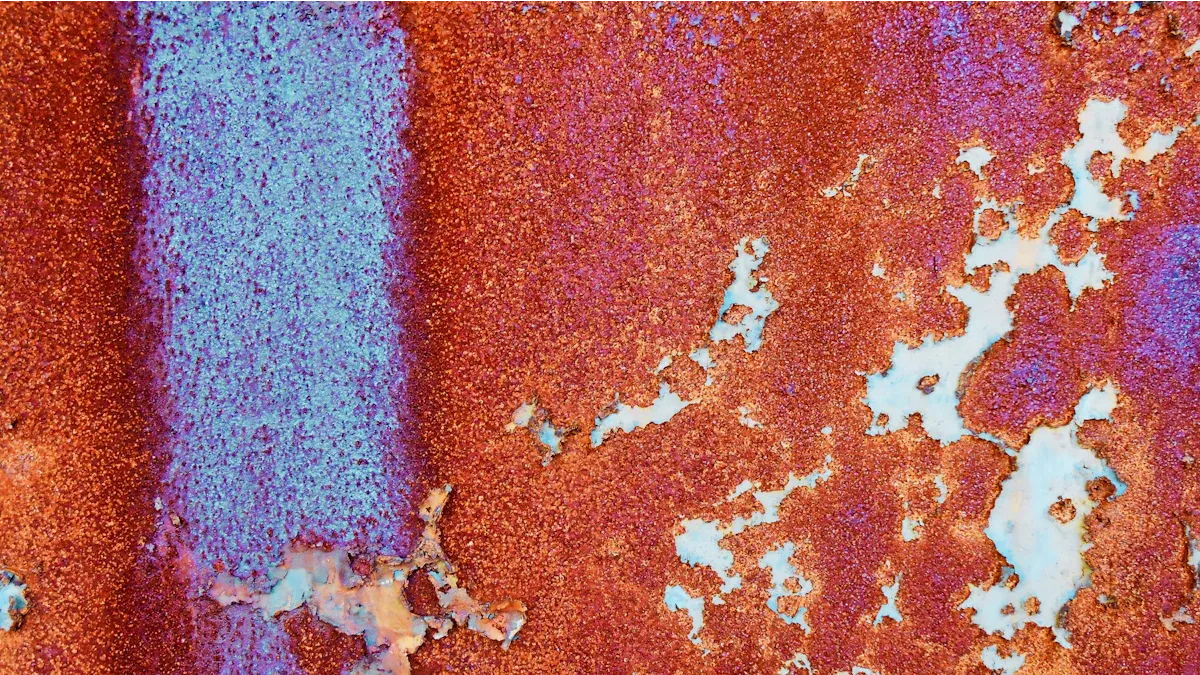

TAC Coating stands out due to its advanced composition and unique properties. You’ll find that it offers exceptional resistance to corrosion, abrasion, and extreme temperatures. Its molecular structure creates a durable barrier that shields equipment from environmental stressors.

Key features include:

- High durability: It withstands mechanical wear and tear.

- Thermal stability: It performs reliably in high-temperature conditions.

- Chemical resistance: It protects against harsh chemicals and corrosive substances.

These properties make TAC Coating a versatile solution for safeguarding critical assets in demanding environments.

Advantages in Extreme Environments

Extreme environments pose challenges like saltwater exposure, high-pressure conditions, and fluctuating temperatures. TAC Coating addresses these issues effectively. You can rely on its ability to prevent corrosion, reduce abrasion, and maintain structural integrity under stress.

TAC Coating ensures equipment longevity by minimizing damage caused by environmental factors.

Its performance in extreme conditions reduces the need for frequent maintenance, saving time and resources. This makes it an ideal choice for industries operating in harsh settings.

Applications in the Oil & Gas Industry

In the oil and gas sector, TAC Coating plays a wichtige rolle in protecting equipment and infrastructure. You’ll see its application in:

- Offshore platforms: It shields structures from saltwater corrosion.

- Pipeline systems: It prevents abrasion caused by transported materials.

- Refinery equipment: It provides thermal protection during high-temperature operations.

These applications demonstrate how TAC Coating enhances reliability and efficiency in critical operations.

Real-World Applications of TAC Coating

Corrosion Resistance in Offshore Platforms

Offshore platforms face constant exposure to saltwater, humidity, and harsh weather. These conditions make corrosion a significant challenge. You can rely on TAC Coating to create a protective barrier that prevents saltwater from damaging metal surfaces. This coating resists the corrosive effects of seawater, ensuring the structural integrity of platforms over time.

Without proper protection, corrosion can weaken critical components and lead to costly repairs or replacements.

TAC Coating not only extends the lifespan of offshore structures but also reduces the frequency of maintenance. This allows you to focus on operations without worrying about unexpected downtime caused by corrosion-related failures.

Abrasion Prevention in Pipeline Systems

Pipelines transport materials like crude oil, natural gas, and other abrasive substances. These materials can wear down the inner surfaces of pipelines over time. TAC Coating provides a durable layer that minimizes abrasion, ensuring smooth material flow and reducing wear.

You’ll notice that pipelines treated with this coating maintain their efficiency for longer periods. This reduces the risk of leaks or ruptures caused by material degradation. Additionally, the coating helps lower operational costs by decreasing the need for frequent inspections and repairs.

By preventing abrasion, TAC Coating enhances the safety and reliability of pipeline systems.

High-Temperature Protection in Refinery Equipment

Refinery equipment operates under extreme heat during processes like distillation and cracking. High temperatures can weaken materials and cause equipment failure. TAC Coating offers exceptional thermal stability, protecting equipment from heat-related damage.

This coating ensures that refinery components maintain their strength and functionality even in high-temperature environments. You can depend on it to improve the efficiency of operations while reducing the risk of unexpected breakdowns.

TAC Coating’s ability to withstand extreme heat makes it an essential solution for refinery applications.

By applying this coating, you can extend the lifespan of refinery equipment and reduce the need for costly replacements.

Broader Benefits of TAC Coating

Economic Impact: Cost Savings and Asset Longevity

You’ll notice that TAC Coating delivers significant economic benefits by reducing maintenance costs and extending the lifespan of equipment. When equipment lasts longer, you spend less on replacements and repairs. This coating minimizes wear and tear, allowing you to allocate resources to other critical areas of your operations.

Tipp: Investing in TAC Coating upfront can save you money in the long run by reducing unexpected downtime and repair expenses.

A study of oil and gas facilities showed that assets treated with TAC Coating required 30% fewer repairs over a five-year period. This reduction in maintenance translates to substantial cost savings. Additionally, the extended lifespan of equipment means fewer disruptions to your operations, improving overall efficiency.

Environmental Sustainability: Reducing Waste and Maintenance

TAC Coating contributes to environmental sustainability by reducing waste and the need for frequent maintenance. When equipment lasts longer, fewer materials end up in landfills. You also reduce the environmental impact of manufacturing new components.

This coating’s durability ensures that you use fewer resources over time. For example, pipelines treated with TAC Coating require fewer replacements, which lowers the demand for raw materials. By choosing this solution, you actively support sustainable practices in your industry.

Note: Sustainability isn’t just about reducing waste; it’s also about minimizing the environmental footprint of your operations.

A comparison of coated versus uncoated equipment revealed that TAC Coating reduces maintenance-related waste by up to 40%. This makes it an eco-friendly choice for companies aiming to meet environmental standards.

Safety Enhancements: Improving Equipment Reliability

Safety is a top priority in the oil and gas industry. TAC Coating improves equipment reliability, reducing the risk of accidents caused by material failure. When equipment performs consistently, you create a safer working environment for your team.

For example, pipelines treated with TAC Coating are less likely to rupture, preventing hazardous leaks. Offshore platforms benefit from enhanced corrosion resistance, which reduces the likelihood of structural failures. These improvements directly contribute to the safety of your operations.

Reliable equipment isn’t just about efficiency; it’s about protecting lives and minimizing risks.

By using TAC Coating, you ensure that your assets remain dependable under extreme conditions. This reliability enhances operational safety and gives you peace of mind knowing your equipment is built to withstand challenges.

TAC Coating plays a vital role in solving challenges in extreme environments. Its durability, cost-effectiveness, and environmental benefits make it an essential solution for the oil and gas industry. By adopting this technology, you can protect your assets, reduce costs, and improve sustainability. Explore its potential to meet your operational needs today.

FAQ

What makes TAC Coating different from traditional coatings?

TAC Coating offers superior resistance to corrosion, abrasion, and extreme temperatures. Its advanced molecular structure ensures durability and reliability in harsh environments, unlike traditional coatings.

Kann TAC Beschichtung auf bestehende Geräte angewendet werden?

Yes, you can apply TAC Coating to both new and existing equipment. It adheres well to various surfaces, enhancing protection without requiring significant modifications.

How long does TAC Coating last in extreme conditions?

TAC Coating provides langzeitschutz, often exceeding five years in extreme environments. Its durability reduces maintenance needs and extends the lifespan of your equipment.

Tipp: Regular inspections can help you maximize the coating’s performance and longevity.