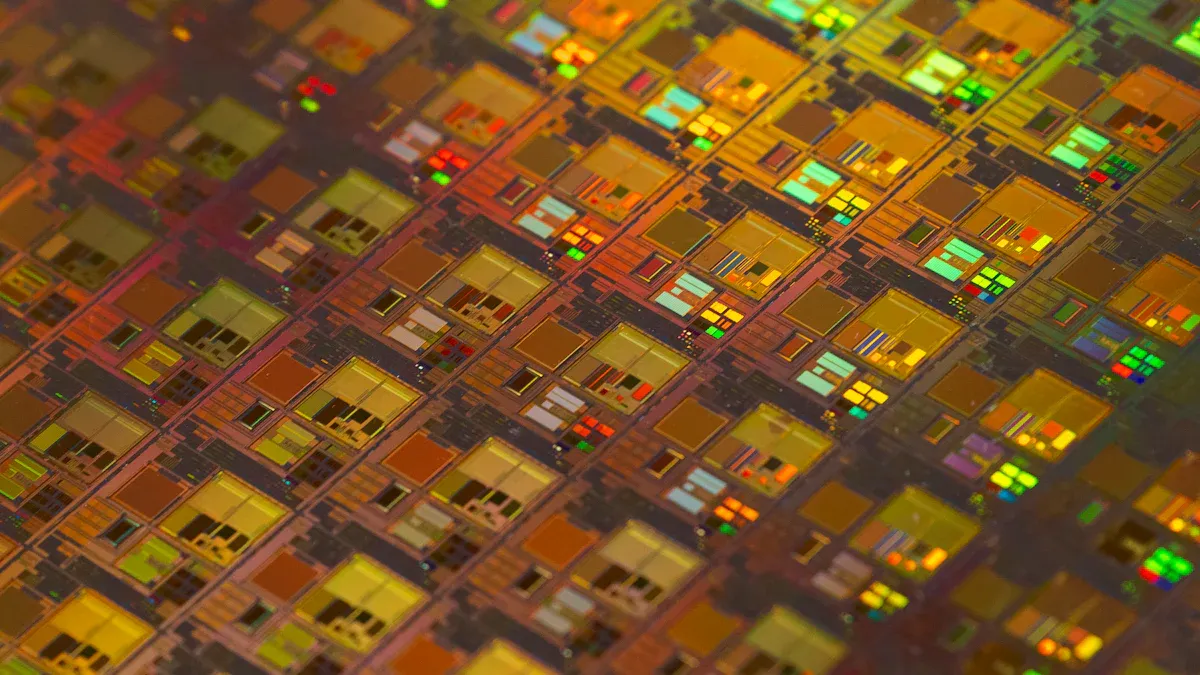

You depend on high-purity graphite for its exceptional performance in SiC Epitaxy. Its superior thermal stability allows for precise temperature regulation, and its uniformity ensures consistent wafer growth. This material is highly resistant to chemical corrosion, even in extreme conditions. Using lower-purity graphite can lead to issues such as contamination and decreased durability, which can negatively impact processes like SIC COATING, TAC COAT, and CVD SIC COATING.

Key Takeaways

- Pure graphite stays stable under heat, keeping temperatures steady for SiC growth. This helps make better wafers.

- Pure graphite lowers the chance of contamination, keeping wafers consistent and reducing defects in the end product.

- Using pure graphite lasts longer and needs less fixing, saving money for makers over time.

Unique Properties of High-Purity Graphite in SiC Epitaxy

Exceptional Thermal Stability and Conductivity

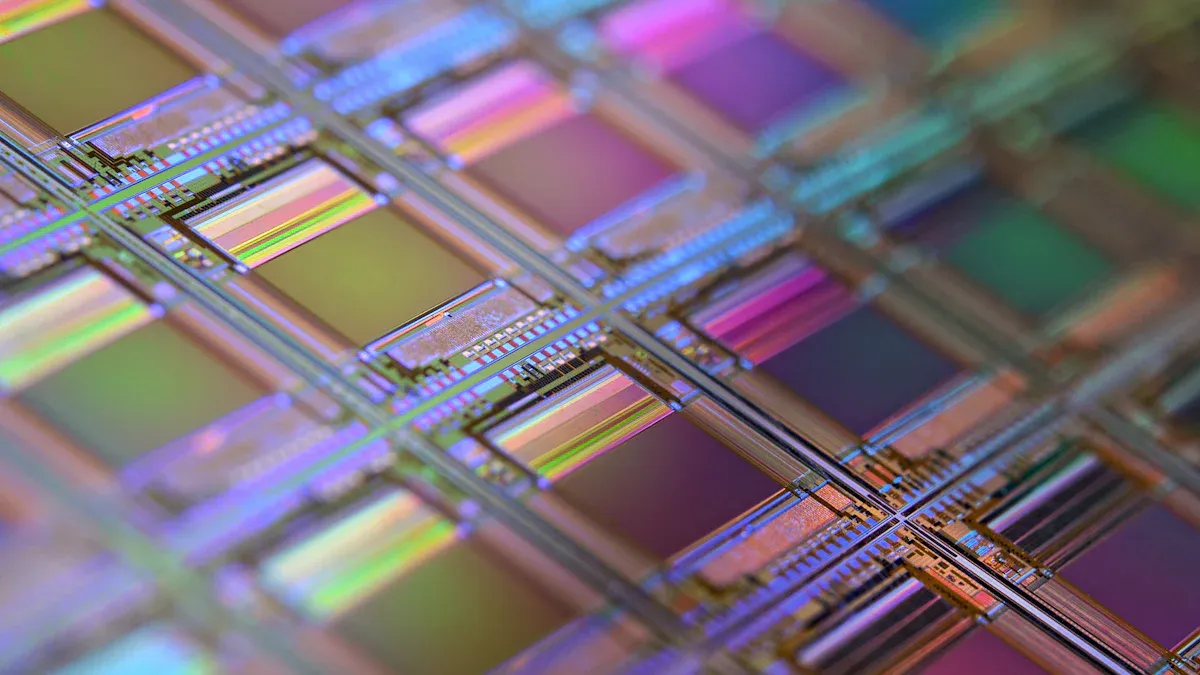

High-purity graphite excels in thermal stability, making it a cornerstone material in SiC Epitaxy. You need a material that can withstand extreme temperatures without breaking down or deforming. High-purity graphite maintains its structure even at temperatures exceeding 3,000°F. This stability ensures that the susceptor provides a consistent environment for wafer growth.

Its exceptional thermal conductivity also plays a vital role. Heat needs to distribute evenly across the susceptor to avoid temperature fluctuations. Uneven heat can lead to defects in the epitaxial layer. High-purity graphite ensures precise temperature control, which is critical for producing high-quality wafers.

Tipp: Always prioritize materials with high thermal stability and conductivity to achieve consistent results in SiC Epitaxy.

High Uniformity for Consistent Epitaxial Growth

Uniformity is another key property of high-purity graphite. When you use a susceptor with a uniform structure, you ensure that the epitaxial growth process remains consistent. Variations in the material can cause uneven deposition, leading to defects in the wafer.

High-purity graphite offers a smooth and homogeneous surface. This uniformity minimizes the risk of irregularities during the growth process. As a result, you achieve wafers with consistent thickness and quality. This is especially important in SiC Epitaxy, where precision directly impacts the performance of the final product.

Note: A uniform susceptor not only improves wafer quality but also reduces the likelihood of costly rework.

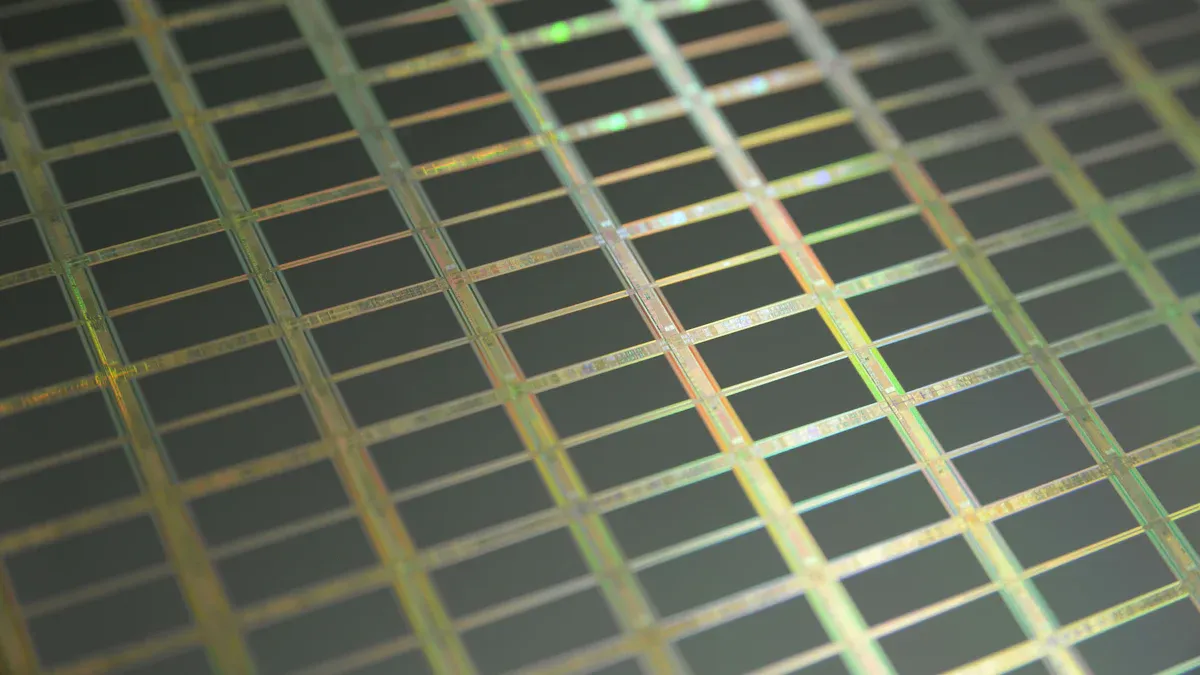

Resistance to Chemical Corrosion in Harsh Environments

The chemical environment in SiC Epitaxy can be highly corrosive. During the process, the susceptor is exposed to reactive gases and high temperatures. Lower-quality materials may degrade or react with these chemicals, leading to contamination.

High-purity graphite resists chemical corrosion, even in these harsh conditions. Its inert nature ensures that it does not release impurities into the system. This resistance protects the integrity of the epitaxial layer and extends the lifespan of the susceptor. By choosing high-purity graphite, you reduce the risk of contamination and maintain a stable process environment.

Reminder: Using materials with strong chemical resistance is essential for achieving reliable and repeatable results in SiC Epitaxy.

Challenges of Using Lower-Purity Graphite in SiC Epitaxy

Risk of Contamination During Epitaxial Growth

Lower-purity graphite often contains impurities that can release contaminants during the epitaxial growth process. These impurities may react with the gases or materials used in SiC Epitaxy, introducing unwanted elements into the system. Contamination can lead to defects in the epitaxial layer, reducing the quality of the wafer. You might notice irregularities in the surface or inconsistencies in the material’s properties. By using lower-purity graphite, you risk compromising the entire process and producing wafers that fail to meet industry standards.

Alert: Contaminated wafers can result in costly rework or even complete rejection of the batch.

Reduced Service Life and Increased Maintenance Costs

Graphite with lower purity tends to degrade faster when exposed to the high temperatures and reactive environments of SiC Epitaxy. This degradation shortens the lifespan of the susceptor, requiring more frequent replacements. You may also face increased maintenance costs due to the need for constant cleaning or repairs. Over time, these expenses can add up, making lower-purity graphite a less economical choice. High-purity graphite, on the other hand, offers better durability and reduces the need for frequent interventions.

Negative Impact on Wafer Quality and Yield

The use of lower-purity graphite can directly affect wafer quality and yield. Impurities in the susceptor material can cause uneven heating or chemical reactions that disrupt the epitaxial growth process. You might observe wafers with inconsistent thickness or structural defects. These issues not only lower the yield but also impact the performance of the final product. For applications requiring precision, such as power electronics, poor wafer quality can lead to significant performance issues.

Tipp: Investing in high-purity graphite ensures consistent wafer quality and maximizes production efficiency.

How High-Purity Graphite Addresses These Challenges

Enhanced Thermal Conductivity for Precise Temperature Control

High-purity graphite provides superior thermal conductivity, which is essential for maintaining precise temperature control during SiC Epitaxy. When you use a susceptor made from this material, heat spreads evenly across its surface. This uniform heat distribution prevents temperature fluctuations that could disrupt the epitaxial growth process.

Inconsistent temperatures often result in defects, such as uneven wafer thickness or structural irregularities. High-purity graphite eliminates these risks by ensuring a stable thermal environment. This stability allows you to achieve the exact conditions needed for high-quality wafer production.

Tipp: To improve temperature control, always choose materials with high thermal conductivity. This ensures consistent results and reduces the likelihood of defects.

Superior Durability for Long-Term Reliability

Durability is another critical advantage of high-purity graphite. This material withstands the extreme conditions of SiC Epitaxy, including high temperatures and exposure to reactive gases. Unlike lower-purity alternatives, high-purity graphite resists wear and tear, maintaining its structural integrity over time.

When you use a durable susceptor, you reduce the need for frequent replacements. This not only lowers maintenance costs but also minimizes downtime in your production process. High-purity graphite ensures long-term reliability, making it a cost-effective choice for manufacturers.

Reminder: Investing in durable materials like high-purity graphite saves you money in the long run by reducing maintenance and replacement expenses.

Improved Process Efficiency and Consistent Wafer Quality

High-purity graphite enhances process efficiency by providing a stable and reliable environment for epitaxial growth. Its uniform structure and resistance to contamination ensure that each wafer meets the highest quality standards. You can produce wafers with consistent thickness, smooth surfaces, and minimal defects.

This consistency directly impacts your production yield. When you achieve high-quality wafers, you reduce waste and improve overall efficiency. High-purity graphite helps you meet industry standards while maximizing your output.

Note: Consistent wafer quality is crucial for applications like power electronics, where precision and reliability are non-negotiable.

High-purity graphite ensures reliable performance in SiC epitaxy. Its thermal stability and chemical resistance protect wafer quality and reduce production risks. Lower-purity graphite introduces contamination and shortens susceptor lifespan. By choosing high-purity graphite, you improve wafer growth and streamline manufacturing processes. This choice supports consistent results and long-term efficiency.

Tipp: Investing in high-purity materials minimizes defects and maximizes production yield.

FAQ

What makes high-purity graphite better than lower-purity alternatives?

High-purity graphite offers superior thermal stability, chemical resistance, and uniformity. These properties ensure consistent wafer quality, longer susceptor lifespan, and reduced contamination risks during SiC epitaxy.

Tipp: Always choose high-purity graphite to avoid defects and maximize efficiency.

How does high-purity graphite improve wafer quality?

Its uniform structure and resistance to impurities create a stable environment for epitaxial growth. This results in wafers with consistent thickness, smooth surfaces, and minimal defects.

Is high-purity graphite cost-effective for manufacturers?

Yes, it reduces maintenance costs, minimizes replacements, and improves production yield. These benefits outweigh the initial investment, making it a cost-effective choice for long-term use.

Reminder: Investing in quality materials saves money and enhances reliability.