Tunnel projects in 2025 demand communication equipment that delivers safety, reliability, and compliance with strict standards. The global market for tunnel communication solutions, including the Industrial IP Weatherproof Telephone for Tunnel Project, continues to grow as infrastructure expands and safety requirements rise.

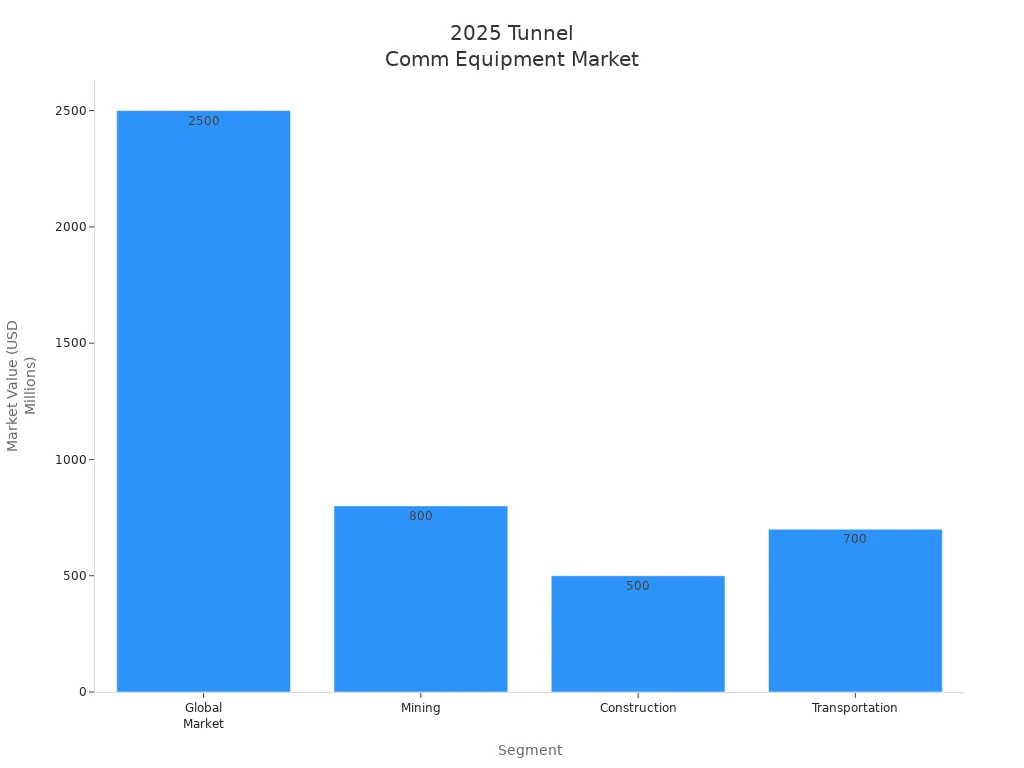

| Segment | Market Value (2025) | Key Drivers and Trends |

|---|---|---|

| Global Market | $2.5 billion | Projected CAGR of 7% through 2033, reaching $4.2 billion; driven by infrastructure investments worldwide |

| Mining | $800 million | High safety requirements, hazardous environments, critical underground operations |

| Construction | $500 million | Need for reliable communication to coordinate workers and equipment, safety compliance |

| Transporte | $700 million | Communication for rail and road tunnels, supporting CCTV, traffic control, and passenger information |

Modern tunnel communication technology advances rapidly. Companies now integrate wireless solutions, fiber optics, and IoT, while products like the ATEX Explosion Proof Telephone, de emergencia Proyección de teléfono, y mining Explosion Proof Telephone support operational safety and future-proof connectivity.

Defining Reliability and Selection Criteria

Key Reliability Metrics for Tunnel Communication

Reliability stands as the foundation of any tunnel communication system. In 2025, project managers and engineers evaluate equipment using several key metrics. These metrics help ensure that communication remains stable and effective, even in the most demanding underground environments.

- Throughput measures how much data the system can transfer over time. High throughput supports clear voice calls and fast data transmission.

- CPU Usage shows how much processing power the equipment uses during operation. Lower CPU usage often means better efficiency and less risk of overheating.

- Latency reflects the time it takes for a message to travel from one point to another. Low latency is critical for real-time communication, especially during emergencies.

- Packet Loss Resilience indicates how well the system handles lost data packets. Strong resilience ensures messages get through, even if some data is lost along the way.

- Availability Vectors and Reliability Matrices help teams track system uptime and performance relationships.

- Capability Vectors show what the communication interfaces can handle.

- Reliability Coefficients provide a quantitative way to compare different systems.

📊 Tip: High system availability, often measured in "nines" (like 99.9% or 99.999%), means less downtime each year. Redundant components, such as backup power supplies or parallel communication paths, can boost uptime and reliability. While Mean Time Between Failures (MTBF) remains a common metric, many experts now look at operational availability and Maintenance Free Operating Period (MFOP) for a more practical view of system performance.

Tunnel safety authorities also recommend a systematic approach to equipment selection. They advise that teams:

- Test communication systems from the tunnel entry to all underground locations after installation.

- Ensure each system has an independent power supply for operation during outages.

- Design networks so that a failure at one point does not disrupt the entire system.

- Use power-assisted voice communication where natural voice is not effective.

- Provide at least two communication methods, including one voice system, in all personnel shafts.

- Test systems at the start of each shift and as needed.

- Equip workers in hazardous, isolated areas with effective emergency communication devices.

Environmental Durability and Compliance with 2025 Standards

Tunnel environments challenge equipment with humidity, dust, vibration, and extreme temperatures. Communication devices must withstand these conditions to ensure long-term performance and safety.

- High IP ratings, such as IP67, protect against dust and water ingress.

- Weatherproof and corrosion-resistant enclosures shield equipment from rain, UV, and harsh chemicals.

- Compliance with NEMA-rated standards ensures protection against environmental hazards.

- Devices must operate reliably across wide temperature ranges and resist vibration from traffic or rail systems.

- Security features, like tamper-proof hardware and secure locks, prevent unauthorized access.

- Flexible mounting options, including wall, pole, or freestanding installations, support various tunnel layouts.

- Pre-wired or field-configurable cable entries simplify installation and maintenance.

🌡️ Note: Humidity and dust can degrade performance, while vibration from drilling or passing vehicles may cause instability. Materials like glass fiber cloth and epoxy resin help protect sensitive electronics, keeping systems stable even in harsh conditions.

To meet evolving standards in 2025, organizations should:

- Analyze all relevant regulations before selecting equipment.

- Compare current practices to standards and address any gaps.

- Keep thorough documentation and use management systems for records.

- Train staff on compliance requirements.

- Monitor and audit systems regularly.

- Use compliance management software to streamline processes.

- Collaborate with industry peers and regulatory bodies.

- Update compliance strategies as standards evolve.

Interference Resistance and Maintenance Considerations

Interference poses a major risk to tunnel communication systems. Sources include inter-cell interference, signal attenuation, and environmental noise from dust, gases, and machinery. These factors can lower the signal-to-interference-plus-noise ratio (SINR) and disrupt communication.

Modern systems use several strategies to combat interference:

- Angle Diversity Receivers (ADRs): These use multiple photodetectors in geometric patterns to reduce channel correlation and improve SINR.

- Signal Combining Schemes: Techniques like select best combining (SBC), equal gain combining (EGC), and maximum ratio combining (MRC) help maintain signal quality.

- Shielded Twisted Pair Cables: These reduce electromagnetic interference, especially when not grounded between transmitter and base station.

- Mesh Networking: Technologies like Kinetic Mesh® create self-optimizing networks that reroute traffic to avoid interference and maintain connectivity.

- Leaky Feeder Systems: VHF and UHF systems designed for tunnels provide robust, reliable coverage and integrate with distributed antenna systems.

🛠️ Maintenance Tip: Regular testing at the start of each shift ensures operational readiness. Redundant systems and easy-to-access enclosures simplify repairs and minimize downtime. Using high-quality, interference-resistant components reduces the need for frequent maintenance and supports long-term reliability.

By focusing on these reliability metrics, environmental standards, and interference mitigation strategies, tunnel project teams can select communication equipment that meets the demands of 2025 and beyond.

Evaluating Technology Options: Industrial IP Weatherproof Telephone for Tunnel Project

Wired vs. Wireless Solutions in Tunnel Environments

Selecting the right communication system for tunnels requires a careful comparison between wired and wireless technologies. Wired networks have long served as the backbone of tunnel communication. They offer high speed, low latency, and stable connections. However, installing cables in tunnels can be complex, time-consuming, and costly. Maintenance often requires shutting down sections of the tunnel, which disrupts operations.

Recent advances in wireless technology have changed the landscape. Modern wireless systems, such as those using the 60 GHz band, now deliver multi-gigabit speeds and low interference. These systems can even connect through thick concrete walls, making them suitable for challenging tunnel environments. Wireless solutions allow for faster deployment and easier expansion. They also reduce installation and maintenance costs because there is no need to lay cables in hazardous or confined spaces.

| Feature | Wired Network | Wireless Network |

|---|---|---|

| Speed | Higher speed, lower latency | Improving speeds, now comparable with new technologies |

| Reliability | Stable, less interference | Enhanced reliability, but still sensitive to some interference |

| Installation | Complex, requires physical cabling | Easier, faster, flexible, and scalable |

| Interference | Minimal due to physical medium | More susceptible, but advanced systems reduce this |

| Coverage | Limited by cable length | Flexible, but signal range and obstacles can affect coverage |

| Bandwidth | Dedicated per device | Shared among devices, but mesh networks improve performance |

| Latency | Lower latency | Slightly higher, but acceptable for most applications |

| Security | More secure, physical connection | Needs strong encryption and network controls |

Wireless communication in tunnels offers several advantages:

- Quick and flexible deployment, especially in dynamic or expanding tunnel projects.

- Real-time communication and instant alerts for improved safety.

- Scalability to support more devices as the tunnel network grows.

- Lower installation and maintenance costs.

The Industrial IP Weatherproof Telephone for Tunnel Project stands out in both wired and wireless setups. Its robust design, high IP67 rating, and compatibility with modern IP protocols make it suitable for integration into either type of network. Project managers can choose the best approach based on the tunnel’s specific needs, knowing that this telephone will deliver reliable performance in any scenario.

Integration with Existing Systems and Future-Proofing

Integrating new communication equipment into existing tunnel systems presents unique challenges. Tunnels have narrow, enclosed structures that complicate signal transmission and equipment placement. Many tunnels also use legacy systems with limited documentation, making upgrades difficult. Teams must coordinate closely to maintain operations during installation and ensure safety at all times.

The Industrial IP Weatherproof Telephone for Tunnel Project addresses these challenges with its flexible, modular design. It supports SIP 2.0 and multiple audio codecs, allowing seamless integration with modern IP-based communication systems. Its wall-mounted installation and programmable function buttons make it adaptable to various tunnel layouts and operational requirements.

Future-proofing is essential for tunnel communication equipment in 2025 and beyond. Key features include:

- Centralized and scalable network management for complex environments.

- Support for VLAN segmentation and device management to enhance security.

- Real-time monitoring and local data control for privacy and reliability.

- Compliance with strict safety standards, including explosion-proof certifications.

- Modular expansion capabilities to accommodate future network growth.

- Compatibility with advanced wireless technologies and helical antennas for improved coverage and resilience.

The Industrial IP Weatherproof Telephone for Tunnel Project meets these requirements. Its rugged construction, advanced telephony features, and compliance with international standards ensure long-term operational performance. Project teams can confidently integrate this telephone into existing systems, knowing it will support future upgrades and evolving safety regulations.

💡 Tip: Modular software solutions and ready-to-use visualization tools help engineers monitor and control tunnel systems efficiently. Choosing equipment that supports these features simplifies integration and reduces downtime.

Vendor Assessment and Support for Tunnel Applications

Selecting the right vendor is as important as choosing the right equipment. Reliable vendors provide not only high-quality products but also strong technical support and after-sales service. For tunnel projects, vendors must demonstrate expertise in harsh and complex environments.

Key factors to consider when assessing vendors include:

- Certifications such as CE, FCC, RoHS, ISO9001, and relevant fiber optics and cabling credentials.

- Proven track record in supplying equipment for tunnels, mining, and other industrial settings.

- In-house manufacturing of spare parts for quality control and quick support.

- Availability of technical documentation, training, and on-site guidance.

- Responsive customer service and maintenance support.

The Industrial IP Weatherproof Telephone for Tunnel Project, produced by JOIWO, exemplifies these qualities. JOIWO manufactures most spare parts in-house, ensuring consistent quality and reliable after-sale support. The telephone meets international certifications and is designed specifically for demanding tunnel environments. Project managers benefit from a partner who understands the unique challenges of tunnel communication and provides solutions tailored to their needs.

🛠️ Note: Always verify vendor certifications and request references from similar tunnel projects. Strong vendor support reduces risk and ensures smooth operation throughout the equipment’s lifecycle.

Project teams should follow clear steps when selecting tunnel communication equipment. They can use systematic methods like multi-criteria decision-making and system theory to improve reliability. Regular reviews help adapt to new risks. The Industrial IP Weatherproof Telephone for Tunnel Project supports long-term safety and performance in these demanding environments.

FAQ

What makes a telephone suitable for tunnel environments?

A telephone for tunnels needs a strong, waterproof case, high IP rating, and resistance to dust, moisture, and vibration. It must work in extreme temperatures and noisy conditions.

How does JOIWO ensure long-term reliability of its tunnel telephones?

JOIWO uses corrosion-resistant materials, in-house manufacturing, and strict quality control. The company meets international standards and provides strong after-sale support for every product.

Can the Industrial IP Weatherproof Telephone integrate with modern tunnel systems?

Yes. The telephone supports SIP 2.0 and multiple audio codecs. It connects easily with IP-based systems and adapts to both wired and wireless network setups.