Industrial plants increasingly invest in safety solutions like the emergency Explosion Proof Telephone. The Eaton ETW Series, an ATEX Explosion Proof Telephone, meets strict standards. Global demand rises, especially in hazardous sectors. Plants choose rugged options, such as mining Explosion Proof Telephone or IP Explosion Proof Telephone, to ensure compliance and reliability.

Key Criteria for Choosing an Emergency Explosion Proof Telephone

Certificaciones de seguridad y cumplimiento

Selecting an de emergencia Proyección de teléfono starts with safety certifications. Devices must meet ATEX and IECEx standards, confirming their use in hazardous zones like Zone 1 and Zone 2. These certifications ensure the telephone’s intrinsic safety design, IP66 waterproof rating, and protection against gas groups IIA/IIB and temperature class T4. Non-compliance can lead to safety hazards and legal risks.

Tip: Always verify certification labels before installation.

Durability and Environmental Resistance

Durability matters in harsh industrial settings. Manufacturers use corrosion-resistant zinc alloy bodies and stainless steel keypads for longevity. IP66 or IP67 ratings protect against water and dust. IK10 impact ratings and wide temperature ranges (from -40°C to +70°C) ensure reliable operation in extreme conditions.

| Feature | Specification |

|---|---|

| IP Rating | IP66/IP67 |

| IK Rating | IK10 |

| Temperatura | -40°C to +70°C |

| Vivienda | Aluminum/Zinc Alloy |

Connectivity and System Integration

Modern plants require telephones that integrate with VoIP/SIP networks, PA systems, and emergency alarms. Features like Power over Ethernet (PoE), party line connectivity, and modular control panels support flexible communication. Integration with plant-wide emergency response systems ensures coordinated alerts and reliable voice communication.

Installation and User-Friendliness

User-friendly features include glove-compatible touchscreens, push-to-talk buttons, and loud audio for noisy environments. Simple installation with adjustable brackets and clear instructions helps reduce setup time. Operators value intuitive interfaces and emergency alert buttons for quick response.

Maintenance and After-Sales Support

Routine inspections, proper installation, and staff training keep devices reliable. Manufacturers offer warranties (typically 1-2 years), repair services, and global customer support. Only authorized repairs maintain explosion-proof safety standards.

Cost-Effectiveness and Value

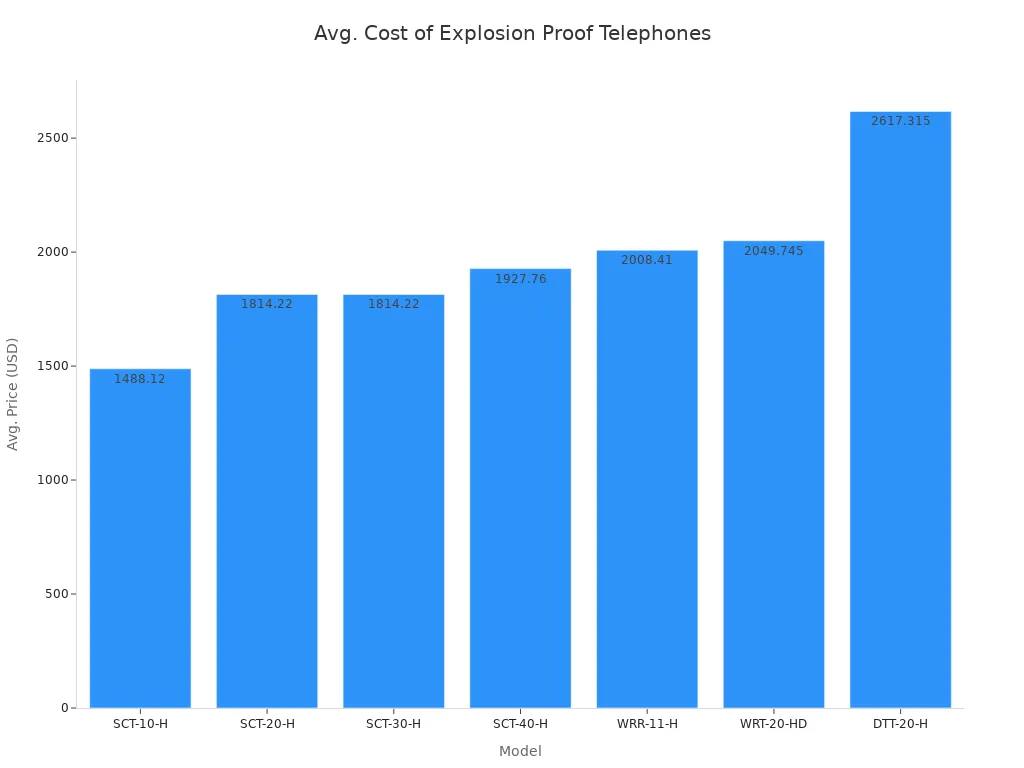

Prices for explosion proof telephones range from $1,488 to over $20,000, depending on features and certifications. Most industrial models fall between $1,500 and $3,000.

Emergency Explosion Proof Telephone Models Compared

Eaton ETW Series vs. Joiwo JWAT Series vs. ae&t ExResistTel

Selecting the right de emergencia Proyección de teléfono model depends on the unique needs of each industrial plant. Each series offers distinct advantages in safety, durability, and integration.

- The Eaton ETW Series stands out for its robust construction and advanced emergency features. Many plants choose this model for its proven reliability and seamless integration with modern plant systems. Its certifications ensure compliance in hazardous environments.

- The Joiwo JWAT Series provides a comprehensive set of certifications, including ATEX, IECEx, UL, and FM. These telephones use rugged, corrosion-resistant materials and sealed enclosures. They withstand harsh chemical plant conditions, extreme temperatures, and high humidity. High IP66/IP67 and IK10 ratings protect against dust, water, and impact. Features such as noise-canceling microphones and programmable keypads support clear communication in noisy environments. Smart connectivity options include LTE support, Android OS compatibility, and integration with plant communication systems. The telephones also support auto-dial functionality and compatibility with both analog and VoIP systems. Flexible installation options and vandal-resistant designs meet the needs of diverse industrial settings.

- The ae&t ExResistTel model focuses on reliability and ease of use. It offers essential safety certifications and a user-friendly interface. Many operators value its straightforward installation and maintenance features.

Note: Plants should match each model’s strengths to their specific operational and safety requirements.

Comparison Table: Features, Certifications, and Specifications

The following table highlights key differences and similarities among the three leading models:

| Feature / Model | Eaton ETW Series | Joiwo JWAT Series | ae&t ExResistTel |

|---|---|---|---|

| Certifications | Atex, iecex | ATEX, IECEx, UL, FM | Atex, iecex |

| Housing Material | Aluminum/Zinc Alloy | Corrosion-resistant Alloy | Polycarbonate/Metal |

| IP Rating | IP66 | IP66/IP67 | IP66 |

| IK Rating | IK10 | IK10 | IK09 |

| Temperature Range | -40°C to +70°C | -40°C to +70°C | -25°C to +60°C |

| Connectivity | Analog, VoIP/SIP | Analog, VoIP, LTE, Android | Análogo, VoIP |

| Special Features | Emergency alert, PA integration | Noise-canceling mic, programmable keypad, remote diagnostics | Loud ringer, easy install |

| Opciones de instalación | Montado en la pared | Wall/freestanding | Montado en la pared |

| Maintenance | Low, with strong support | Low, remote diagnostics | Low, easy access |

| Best For | Oil & Gas, Mining, Utilities | Chemical, Hazardous, Multi-system plants | General Industry, Utilities |

🛡️ Tip: Always review the latest technical datasheets before making a final selection.

Model-by-Model Analysis of Emergency Explosion Proof Telephones

Eaton ETW Series: Strengths, Weaknesses, Best Applications

The Eaton ETW Series offers strong performance in demanding industrial settings. Its main strengths include:

- Robust construction with high resistance to impact and harsh weather.

- Comprehensive safety certifications, including ATEX and IECEx.

- Seamless integration with plant systems for emergency alerts and communication.

Some users note that the ETW Series may have a higher upfront cost compared to other models. However, its reliability and support often justify the investment.

The Eaton ETW Series is commonly deployed in the following applications:

- Indoor lighting control for large municipal and industrial facilities.

- Motor and pump control in water treatment plants and exhaust fan management.

- Scheduled circuit management in shared workspaces and lobbies.

These features make the ETW Series a versatile choice for energy-efficient lighting and essential equipment scheduling in hazardous environments.

Joiwo JWAT Series: Strengths, Weaknesses, Best Applications

Industry experts highlight several advantages of the Joiwo JWAT Series:

- Offers both analog and VOIP telephone options.

- Built with 304 stainless steel for high mechanical strength.

- Vandal-resistant handset with internal steel lanyard.

- Zinc alloy keypad with volume control.

- Magnetic hook switch and optional noise-canceling microphone.

- Flexible installation for wall mounting or embedding.

- Weatherproof protection rated at IP65.

- Self-manufactured spare parts for easy maintenance.

- Meets CE, FCC, RoHS, and ISO9001 standards.

No major weaknesses have been identified for this series.

The Joiwo JWAT Series suits harsh industrial environments with explosion risks, such as chemical plants, mining sites, and gasoline stations. It also works well in noisy production areas, control rooms, and offices, where soundproof communication improves productivity.

ae&t ExResistTel: Strengths, Weaknesses, Best Applications

The ae&t ExResistTel model focuses on reliability and ease of use. Its strengths include a user-friendly interface and essential safety certifications. Operators appreciate its straightforward installation and low maintenance needs. However, it may not offer as many advanced features or connectivity options as other models.

This model fits general industry and utility environments where basic emergency Explosion Proof Telephone functions are required, and where ease of use and quick installation are priorities.

Decision Guide for Selecting an Emergency Explosion Proof Telephone

Step-by-Step Checklist for Plant Managers

Plant managers can follow a clear process to select the right emergency Explosion Proof Telephone for their facility. This checklist helps ensure safety, compliance, and operational efficiency:

- Identify the hazardous area classification for each plant zone.

- Review local and international safety regulations, such as ATEX or IECEx.

- List all integration needs, including compatibility with existing communication and control systems.

- Evaluate environmental conditions, such as temperature extremes, dust, and moisture.

- Compare telephone models for certifications, durability, and connectivity.

- Check installation requirements and user interface features.

- Assess manufacturer support, warranty, and maintenance services.

- Calculate total cost of ownership, including installation and long-term support.

📝 Tip: Involve safety officers and IT specialists in the selection process to cover all technical and compliance aspects.

Matching Plant Requirements to Telephone Features

Plant requirements often depend on hazardous area classification and integration needs. Managers should select equipment certified for the specific hazardous area to ensure safety compliance. Devices must be intrinsically safe or explosion-proof to prevent ignition in dangerous atmospheres. Compatibility with existing communication and control systems allows seamless integration and reliable operation.

- Choose telephones with low energy signaling and fault tolerance to reduce ignition risks.

- Use barrier devices or intrinsically safe cases for portable units.

- Prioritize durability, reliability, and strong manufacturer support.

- Simplify circuitry to lower ignition risk and make maintenance easier.

- Always verify certifications like ATEX or HAZLOC for hazardous environments.

Hazardous area classifications, such as Clase I, División 1, define the risks present and guide equipment selection. Emergency Explosion Proof Telephone models must meet these standards, using enclosures that contain internal ignition sources and prevent sparks from escaping. This approach ensures both safety and operational integration in hazardous plants.

Eaton ETW Series leads in reliability and compliance for industrial plants in 2025. Plant managers improve safety and performance by matching telephone selection to hazards, integration needs, and budgets:

- Hazard assessment reduces safety gaps and prevents accidents.

- Compliance with ATEX regulations protects personnel and avoids fines.

- Environmental considerations lower maintenance costs.

- Budget planning balances cost and safety.

- Maintenance and training preserve equipment integrity.

Managers can use the decision guide to select the best emergency Explosion Proof Telephone for their facility.

FAQ

What is an explosion proof telephone?

An explosion proof telephone resists ignition in hazardous areas. It uses special enclosures and components to prevent sparks from causing fires or explosions.

How often should plant staff inspect explosion proof telephones?

Plant staff should inspect explosion proof telephones every three to six months. Regular checks help maintain safety and ensure reliable operation in hazardous environments.

¿Pueden los teléfonos a prueba de explosión conectarse a los sistemas VOIP modernos?

Yes, many explosion proof telephones support VoIP or SIP protocols. They integrate with digital plant communication systems for clear, reliable emergency calls.

Tip: Always confirm compatibility with your plant’s existing network before purchasing.