Silicon Carbide Coatings play a crucial role in industrial and high-performance environments. These coatings enhance durability, resist extreme temperatures, and improve wear resistance. When choosing a coating method, you need to understand how each process aligns with your specific needs. This comparison will help you make informed decisions for optimal performance.

Key Takeaways

- Silicon Carbide Coatings make things last longer and handle heat well. They are great for tough jobs.

- Pick a coating method that fits your needs: CVD for exact details, PVD for thin layers, and thermal spraying for cheaper thick coatings.

- Think about what you need, your budget, and how it should work to choose the right coating method.

Overview of Silicon Carbide Coatings

General properties and benefits

Silicon Carbide Coatings stand out for their exceptional properties. These coatings are highly durable, offering excellent resistance to wear and abrasion. They can withstand extreme temperatures, making them ideal for high-heat environments. Their chemical stability ensures they resist corrosion, even when exposed to harsh chemicals or oxidizing conditions.

You’ll also find that these coatings have impressive thermal conductivity. This property allows them to dissipate heat efficiently, which is critical in applications like electronics and aerospace. Additionally, their hardness ranks close to that of diamonds, providing superior protection against mechanical damage. With these benefits, Silicon Carbide Coatings enhance the lifespan and performance of various components.

Common industrial applications

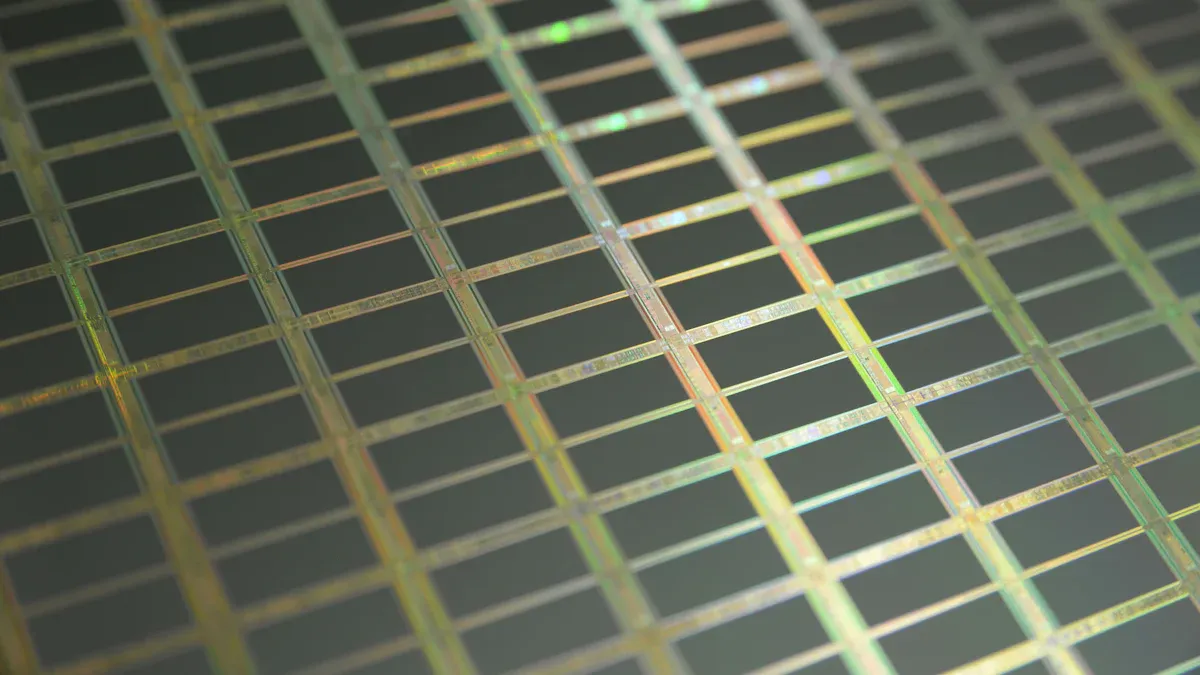

You’ll encounter Silicon Carbide Coatings in a wide range of industries. In aerospace, they protect engine components from high temperatures and wear. In the semiconductor industry, they serve as protective layers for wafers and other delicate parts. Energy sectors use these coatings in turbines and heat exchangers to improve efficiency and durability.

Manufacturers also rely on these coatings for tools and machinery that face constant friction. For example, cutting tools coated with silicon carbide last longer and perform better. Even in medical devices, these coatings provide biocompatibility and resistance to sterilization processes. Their versatility makes them a go-to solution for demanding industrial needs.

Chemical Vapor Deposition (CVD) Silicon Carbide Coatings

Process overview

Chemical Vapor Deposition (CVD) is a widely used method for applying Silicon Carbide Coatings. In this process, you introduce a mixture of gases, typically containing silicon and carbon, into a reaction chamber. These gases react at high temperatures, often exceeding 1,000°C, to form a thin, uniform layer of silicon carbide on the substrate. The process occurs in a controlled environment to ensure precision and consistency. You can adjust parameters like temperature, pressure, and gas composition to achieve specific coating properties.

Advantages and performance characteristics

CVD offers several advantages when it comes to Silicon Carbide Coatings. The method produces coatings with exceptional purity and uniformity, which is critical for applications requiring high precision. These coatings exhibit excellent adhesion to the substrate, ensuring long-lasting performance. You’ll also benefit from their resistencia superior al desgaste, corrosion, and high temperatures. CVD coatings are ideal for industries like aerospace and semiconductors, where durability and thermal stability are essential.

Limitations and challenges

Despite its benefits, CVD has some limitations. The process requires high temperatures, which may not be suitable for all materials. It also involves complex equipment and strict control of operating conditions, making it expensive and time-consuming. Additionally, the deposition rate is relatively slow, which can limit its use for large-scale applications. You should carefully evaluate these factors when considering CVD for your coating needs.

Physical Vapor Deposition (PVD) Silicon Carbide Coatings

Process overview

Physical Vapor Deposition (PVD) is another method for applying Silicon Carbide Coatings. This process involves converting solid materials into a vapor phase and then depositing them onto a substrate. It typically occurs in a vacuum chamber. The material, often silicon carbide, is heated until it evaporates. The vapor then condenses on the surface of the target object, forming a thin, uniform coating. You can control factors like temperature, pressure, and deposition rate to achieve specific results. PVD is a versatile technique used for creating high-quality coatings.

Advantages and performance characteristics

PVD offers several benefits. It produces coatings with excellent hardness and wear resistance. These properties make it ideal for tools and components exposed to friction. The process also creates thin, precise layers, which are essential for applications requiring accuracy. PVD coatings adhere well to substrates, ensuring durability. Additionally, this method operates at lower temperatures compared to CVD, making it suitable for materials sensitive to heat. You’ll find PVD coatings in industries like electronics, automotive, and aerospace.

Limitations and challenges

While PVD has advantages, it also has drawbacks. The process requires expensive equipment and skilled operators, which increases costs. It is less effective for coating large or irregularly shaped objects. The coatings may also be thinner than those produced by other methods, limiting their use in heavy-duty applications. You should evaluate these factors when considering PVD for your needs.

Thermal Spraying Silicon Carbide Coatings

Process overview

Thermal spraying is a versatile method for applying Silicon Carbide Coatings. In this process, you use a high-temperature heat source, such as a plasma or combustion flame, to melt silicon carbide particles. These molten particles are then propelled toward the surface of the substrate using a high-velocity gas stream. When the particles hit the surface, they rapidly cool and solidify, forming a dense and durable coating. This technique allows you to coat large or irregularly shaped objects with ease. It also offers flexibility in controlling the thickness and texture of the coating.

Advantages and performance characteristics

Thermal spraying provides several benefits. It enables you to apply thick coatings, which are ideal for heavy-duty applications. The process is highly efficient, allowing you to cover large areas quickly. Thermal-sprayed coatings exhibit excellent wear resistance, making them suitable for components exposed to friction or abrasion. They also perform well in high-temperature environments, maintaining their integrity under extreme conditions. This method works with a wide range of materials, giving you the flexibility to customize coatings for specific needs.

Limitations and challenges

Despite its advantages, thermal spraying has some limitations. The process requires specialized equipment and skilled operators, which can increase costs. Achieving uniform coatings on complex geometries may be challenging. The bond strength between the coating and substrate might not match that of other methods like CVD. Additionally, thermal spraying may produce coatings with higher porosity, which could reduce their resistance to corrosion. You should weigh these factors carefully when considering this method for your application.

Other Types of Silicon Carbide Coatings

Sponge-type coatings and their applications

Sponge-type coatings offer a unique structure that mimics the porous nature of a sponge. These coatings are created by depositing silicon carbide onto a substrate in a way that forms interconnected pores. This design allows for excellent thermal shock resistance and lightweight properties. You’ll find these coatings particularly useful in applications requiring high surface area, such as catalytic converters or filtration systems. Their ability to handle rapid temperature changes makes them ideal for environments where thermal cycling occurs frequently.

Sputtering target coatings for thin-film deposition

Sputtering target coatings are essential for creating thin films of silicon carbide. In this process, a sputtering target made of silicon carbide is bombarded with high-energy particles, causing atoms to eject and deposit onto a substrate. This method produces ultra-thin, uniform coatings with precise control over thickness. You’ll often see these coatings in electronics, where they enhance the performance of semiconductors and optical devices. Their ability to form highly accurate layers makes them indispensable in industries requiring precision.

Wool-type coatings for thermal insulation

Wool-type coatings consist of silicon carbide fibers arranged in a wool-like structure. These coatings excel at providing thermal insulation due to their low thermal conductivity and high-temperature resistance. You’ll find them in applications like furnace linings and heat shields, where maintaining thermal stability is critical. Their lightweight nature also reduces the overall weight of components, making them suitable for aerospace and energy industries.

Comparison of Silicon Carbide Coating Methods

Durabilidad y resistencia al desgaste

When it comes to durability, each coating method offers unique strengths. CVD coatings excel in creating dense, uniform layers that resist wear and abrasion. This makes them ideal for applications where components face constant friction or mechanical stress. PVD coatings, while thinner, still provide excellent hardness and wear resistance, especially for tools and precision parts. Thermal spraying, on the other hand, allows for thicker coatings, which are better suited for heavy-duty applications. However, thermal-sprayed coatings may have higher porosity, which can slightly reduce their wear resistance compared to CVD or PVD methods.

Tip: If your application involves high levels of friction or abrasive conditions, prioritize methods like CVD or PVD for their superior wear resistance.

Temperature resistance and thermal stability

Silicon Carbide Coatings are known for their ability to withstand extreme temperatures. Among the methods, CVD coatings offer the highest thermal stability due to their dense and pure structure. They perform exceptionally well in high-heat environments, such as aerospace engines or semiconductor manufacturing. PVD coatings also provide good temperature resistance but may not match the performance of CVD in ultra-high-temperature conditions. Thermal-sprayed coatings can handle high temperatures effectively, but their performance may vary depending on the coating’s porosity and thickness.

If your application involves rapid temperature changes, sponge-type coatings might be worth considering. Their porous structure enhances thermal shock resistance, making them suitable for environments with frequent thermal cycling.

Cost-effectiveness and manufacturing complexity

Cost and complexity often play a significant role in choosing a coating method. CVD is the most expensive option due to its high-temperature requirements and complex equipment. It also demands precise control over operating conditions, which increases manufacturing time and costs. PVD is slightly more cost-effective, as it operates at lower temperatures and is less complex. However, it still requires specialized equipment and skilled operators. Thermal spraying stands out as the most economical option for large-scale or heavy-duty applications. It allows you to coat large areas quickly, reducing production time and costs.

Note: While thermal spraying is cost-effective, it may not provide the same level of precision or uniformity as CVD or PVD. Consider your budget and performance needs carefully.

Application suitability across industries

Each coating method aligns with specific industrial needs. CVD coatings are perfect for industries like aerospace and semiconductors, where precision, durability, and thermal stability are critical. PVD coatings find their niche in electronics, automotive, and tooling applications, thanks to their hardness and wear resistance. Thermal spraying is widely used in energy, manufacturing, and heavy machinery sectors, where thick, durable coatings are essential.

For specialized applications, other types of Silicon Carbide Coatings may be more suitable. For instance, sputtering target coatings are ideal for thin-film deposition in electronics, while wool-type coatings excel in thermal insulation for furnaces and heat shields.

Pro Tip: Match the coating method to your industry’s specific requirements. For example, choose CVD for high-precision aerospace components or thermal spraying for large-scale industrial machinery.

Practical Recommendations for Selecting Silicon Carbide Coatings

Key factors to consider (e.g., application, budget, performance needs)

When selecting a coating method, you need to evaluate several key factors to ensure the best fit for your application. Start by identifying the specific requirements of your project. Consider the operating environment, such as temperature, exposure to chemicals, or mechanical stress. For example, if your application involves high heat, prioritize methods like CVD that offer superior thermal stability.

Budget is another critical factor. Some methods, like CVD, involve higher costs due to complex equipment and processes. If cost-efficiency is a priority, thermal spraying might be a better choice, especially for large-scale applications. However, you should balance cost with performance needs to avoid compromising on quality.

Performance expectations also play a significant role. Think about the durability, wear resistance, and coating thickness required for your application. For precision tools or components, PVD might be the ideal choice due to its ability to create thin, accurate layers. On the other hand, heavy-duty machinery may benefit from the thicker coatings provided by thermal spraying.

Tip: Always match the coating method to the specific demands of your project. This approach ensures optimal performance and cost-effectiveness.

Silicon Carbide Coatings offer unmatched durability, temperature resistance, and versatility. Each method—CVD, PVD, and thermal spraying—suits specific needs.

Takeaway: Choose CVD for precision, PVD for thin layers, or thermal spraying for cost-effective thick coatings. Match the method to your industry’s demands to maximize performance and efficiency.

These coatings empower industries like aerospace, energy, and electronics to achieve superior results.

FAQ

What is the best method for coating large surfaces?

Thermal spraying works best for large surfaces. It allows you to apply thick coatings quickly and efficiently, making it ideal for heavy-duty industrial applications.

Tip: Use thermal spraying for cost-effective, large-scale projects.

Can Silicon Carbide Coatings handle rapid temperature changes?

Yes, sponge-type coatings excel in handling rapid temperature changes. Their porous structure provides excellent thermal shock resistance, making them suitable for environments with frequent thermal cycling.

Which coating method is most cost-effective?

Thermal spraying offers the most cost-effective solution. It reduces production time and works well for large-scale applications, though it may lack the precision of CVD or PVD.

Note: Balance cost with performance needs to choose the right method.