An analog Industrial Telephone serves as a lifeline in hazardous locations, including manufacturing plants and offshore platforms. Many industrial sites, about 30%, rely on these devices for dependable communication, especially where digital systems cannot operate. A rugged Industrial Telephone, a Marine Industrial Telephone, or an ATEX Industrial Telephone ensures workers stay connected and safe in demanding conditions.

Analog Industrial Telephone: Definition and Core Role

Technical Definition

An analog Industrial Telephone stands out as a specialized device built for voice communication in tough industrial settings. Engineers design these telephones to operate in hazardous areas, such as chemical plants or offshore rigs. Key features include:

- Explosion-proof and weatherproof construction, often rated IP66 or IP67

- Aluminum alloy die-cast body for high durability

- Vandal-resistant handset and reinforced cord

- Certified for use in explosive atmospheres (ATEX, IECEx)

- Suitable for Zone 1 and Zone 2 hazardous locations

- Telephone line powered, eliminating the need for external AC power

- Inductive coupler for hearing-impaired users

- Compliance with global standards like CE, FCC, and RoHS

Note: These telephones can function in extreme temperatures, from -45°C to +70°C, and withstand up to 95% humidity.

| Attribut | Description |

|---|---|

| Device Type | Line-powered analog industrial telephone |

| Environment Suitability | Hazardous and industrial environments |

| Housing Material | High impact glass fibre-reinforced polyester (GRP), impact and shock resistant |

| Protection Rating | IP66 (weatherproof), explosion protection certifications |

| Operating Temperature | -45°C to +70°C |

| Humidity | Up to 95% non-condensing |

| Alimentation électrique | Drawn from telephone line, no external AC supply required |

| Features | Noise-canceling microphone, magnetic reed hook switch, corrosion-resistant hardware |

| Compliance Standards | FCC, RoHS, CE, ISO9001, ATEX, IECEx |

| Usage | Reliable communication tool in hazardous zones, suitable for extreme conditions |

Functional Role in Industry

The analog Industrial Telephone plays a vital role in maintaining safety and efficiency in industrial operations. Unlike standard telephones, these devices provide direct, always-available communication. Workers can use them during emergencies, even if the main power supply fails. The circuit design allows immediate voice transmission without dialing, which proves essential in critical situations.

| Core Function | Analog Industrial Telephones (Sound Powered) | Standard Industrial Telephones |

|---|---|---|

| Power Requirement | Operate without any external power source; rely on sound energy conversion | Require external power or battery backup |

| Microphone Technology | Use dynamic microphones converting sound pressure directly into electrical current | Use microphones designed to modulate supplied current |

| Circuit Design | Always-active circuits allowing immediate communication without dialing | Require dialing or call setup |

| Reliability & Usage | Rugged, fail-safe, suitable for emergency or power-loss scenarios | May not function during power loss |

| Communication Mode | Direct voice communication, often point-to-point or multi-station | Typically connected to centralized telephone systems |

These features ensure that the analog Industrial Telephone remains a trusted tool for communication in environments where reliability and speed are critical.

Key Features of Analog Industrial Telephone for Harsh Environments

Rugged Construction

Engineers design every analog Industrial Telephone to survive the toughest industrial conditions. The housing often uses stainless steel or cold-rolled steel with a powder-coated finish. This construction resists impacts, corrosion, and vandalism. The handset cord is usually made from stainless steel or armored material, making it difficult to cut or damage. Metal buttons and reinforced keypads add another layer of protection against heavy use and abuse.

| Matériel/Caractéristiques | Description |

|---|---|

| Housing Material | Stainless steel housing with cold rolled steel back-cover, powder coated |

| Boutons | Vandal resistant metal buttons |

| Handset Cord | Stainless steel cord |

| Additional Quality | Alloy material with salt mist test compliance |

| Durability Focus | Vandal-proof and weatherproof construction suitable for industrial use |

These materials and features ensure the telephone can withstand daily wear and tear in factories, refineries, and outdoor locations.

Weather and Environmental Resistance

An analog Industrial Telephone must operate in environments filled with dust, water, and chemicals. Manufacturers give these devices high ingress protection (IP) ratings, such as IP66 ou IP67. These ratings mean the telephone is dust-tight and can resist strong water jets or even temporary immersion. The enclosure uses corrosion-resistant die-cast aluminum or glass fiber-reinforced polyester. Hermetically sealed components keep out moisture and dirt, while powder coatings protect against salt and chemicals.

Note: IP66 means the device resists high-pressure water jets, while IP67 means it can survive temporary immersion in water.

Industrial telephones also meet standards like EN60950 for electrical safety and IK09 for impact protection. These certifications confirm the device’s ability to function in extreme temperatures, from -40°C to +70°C, and in explosive or corrosive atmospheres.

Noise-Canceling Audio

Factories, mines, and oil rigs can be very loud. To ensure clear communication, analog Industrial Telephone models use noise-canceling microphones and advanced audio circuits. These features reduce background noise by up to 34 decibels and improve the signal-to-noise ratio by as much as 18 decibels. Workers can hear and be heard, even when heavy machinery operates nearby.

| Noise-Canceling Feature | Decibel Reduction / Improvement |

|---|---|

| Uplink far-field noise suppression (LMV1099 at 1 kHz) | 34 dB |

| Near-field signal-to-noise ratio (SNR) enhancement | 6 dB to 18 dB |

| Downlink SNR improvement | 16 dB |

This technology helps prevent misunderstandings and supports safety in noisy environments.

Reliable Power Supply

Analog Industrial Telephone devices often draw power directly from the telephone line. This design removes the need for external batteries or AC power. Even during a power outage, the telephone remains operational. Modern analog chips use energy-efficient designs, reducing standby current to microampere levels. Some models include backup batteries or power-saving modes, which extend operational time during emergencies.

Tip: Line-powered telephones offer a major advantage in remote or hazardous areas where power supply interruptions are common.

Simple and Intuitive Operation

Workers in industrial settings need to use communication devices quickly, sometimes while wearing gloves. The analog Industrial Telephone features large, weatherproof keypads and clear labeling. Many models include programmable speed-dial buttons for fast access to emergency contacts. The handset fits comfortably in the hand, and the hook switch is often magnetic or hermetically sealed for reliability.

- Large, tactile buttons for easy use

- Weatherproof keypads operable with gloves

- Clear instructions and labeling

- Simple call setup, often with one-touch dialing

This straightforward design reduces training time and ensures anyone can use the telephone in an emergency.

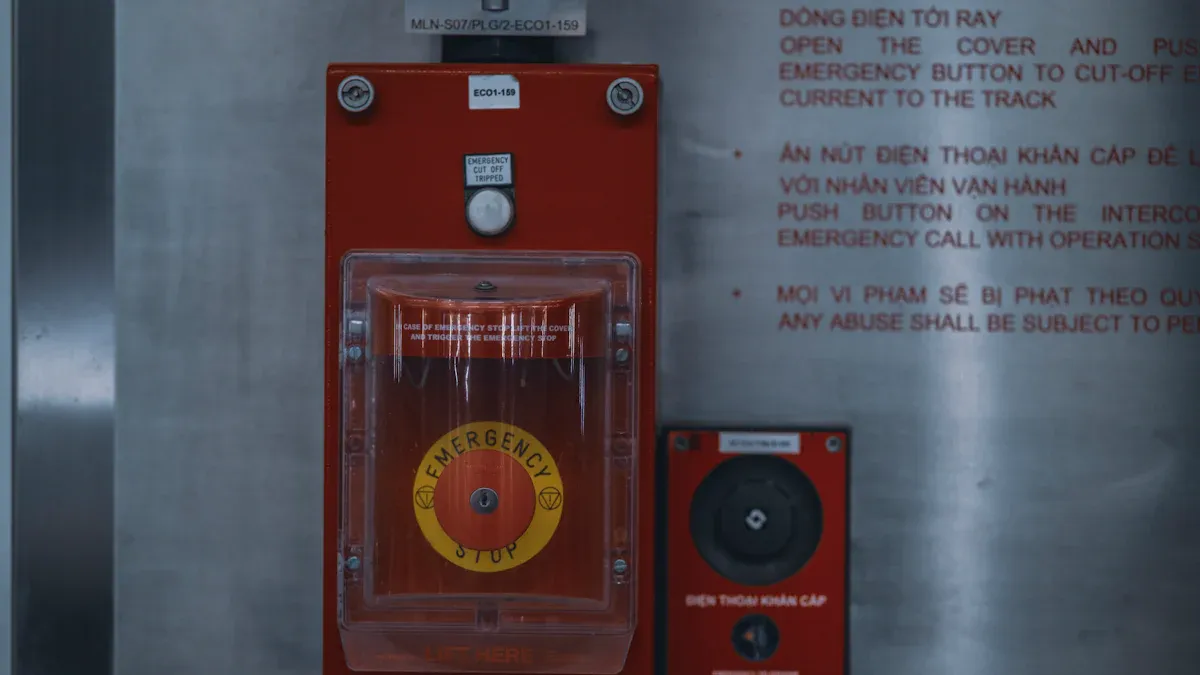

Emergency and Safety Functions

Safety is a top priority in hazardous environments. The analog Industrial Telephone includes several caractéristiques d'urgence. Explosion-proof and waterproof designs allow safe use in oil platforms, mines, and chemical plants. Many models have full keypads with programmable emergency call buttons. External loudspeakers and flashing beacons alert workers during emergencies. The enclosure is certified for use in explosive gas and dust zones, and the device can operate in extreme temperatures.

| Catégorie de fonctionnalités | Specific Emergency Features and Characteristics |

|---|---|

| Construction | Explosion-proof, weatherproof cast aluminum enclosure; corrosion-resistant aluminum alloy die-casting housing |

| Environmental Protection | High ingress protection ratings (IP66 to IP67); certified for Dust & Gas Zones (Zone 1, Zone 2 for gases; Zones 20, 21, 22 for dust) |

| Durability | Impact protection IK10; temperature range -40°C to +70°C; salt & corrosion resistant casing |

| Communication Quality | Noise-canceling microphone; hermetically sealed non-contact hook switch; STI approved sound quality (STI 0.9) |

| Emergency Signaling | Loud ringing volume approx. 90 dB(A) at 1m; external horn speaker up to 110 dB(A) |

| Keypad and Controls | Full programmable keypad with 15 buttons including emergency SOS functions; weatherproof keypad usable with gloves |

| Power and Connectivity | Power supply from analog telephone network or 24V DC; Power over Ethernet (PoE); RJ45 Ethernet socket with IP67 plug connector |

| Remote Management | Web interface and server-based configuration; remote management software for installation and maintenance |

| Installation Options | Wall, column, or structural mounting |

These features ensure workers can call for help quickly and receive alerts, even in the most dangerous situations.

How Analog Industrial Telephone Features Enable Reliable Operation

Withstanding Extreme Temperatures

Industrial sites often face temperature extremes. Manufacturers design telephones to operate in both freezing and scorching conditions. For example, the JREX106 model works reliably from -45°C to +70°C. The Emergency System Industrial Telephone JREX106-A01-CB-Analogue operates between -40°C and +70°C, with storage tolerance up to 80°C. The Explosion-proof Ex II2GD TLA 2229 A1 model functions from -40°C to +60°C.

| Model | Plage de température de fonctionnement | Storage Temperature Range |

|---|---|---|

| JREX106-A01-CB-Analogue | -40°C à +70°C | -45°C to +80°C |

| Explosion-proof Ex II2GD TLA 2229 A1 | -40°C to +60°C | – |

These wide ranges ensure reliable communication, even in the most challenging climates.

Protection Against Dust and Moisture

Factories, tunnels, and outdoor sites expose equipment to dust and water. Telephones use corrosion-resistant cast aluminum or die-cast alloy cases. They feature weatherproof keypads and armored cords. Many models achieve IP66, IP67, or even IP68 ratings, which means they resist dust and can withstand powerful water jets or immersion.

| Feature | Description |

|---|---|

| Case Material | Corrosion resistant cast aluminum alloy, weatherproof |

| Protection | Protection complète contre l'infiltration de poussières et d'humidité |

| IP Rating | Up to IP68 waterproof protection |

| Keypad | Weatherproof, zinc alloy or rubber |

| Handset | Vandal resistant, armored cord, noise-canceling microphone |

| Application | Mining, tunnels, marine, steel, chemical plants, outdoor sites |

These features keep internal components safe and maintain performance in wet or dusty environments.

Performance in High-Noise Areas

Industrial environments can reach noise levels up to 80 dB, similar to a busy factory floor. Telephones maintain clear speech at these levels. They use several technologies to enhance audio clarity:

- Annulation active du bruit (ANC) removes background noise in real time.

- Digital Signal Processing (DSP) boosts voice signals and reduces interference.

- Automatic Gain Control (AGC) adjusts volume based on ambient noise.

- Directional microphones focus on the speaker’s voice.

- High Sound Pressure Level (SPL ≥ 100dB) ensures messages remain audible.

Noise-canceling headsets and hearing aid compatible microphones further improve communication, even in the loudest settings.

Durability Under Vibration and Impact

Heavy machinery and moving equipment create constant vibration and risk of impact. Telephones use thick die-cast aluminum cases and reinforced mounting. Vandal-resistant handsets and armored cords prevent damage. Weatherproof keypads and sealed enclosures protect against shocks. These design choices help the telephone survive drops, bumps, and daily wear in tough industrial locations.

Note: Rigorous testing and international certifications confirm the durability of these devices in real-world conditions.

Typical Use Cases for Analog Industrial Telephone

Manufacturing Plants

Manufacturing plants often operate around the clock. Workers face loud machinery, dust, and frequent vibrations. In these settings, reliable communication tools help teams coordinate production and respond to emergencies. Rugged telephones with weatherproof housings and noise-canceling microphones allow clear conversations, even on busy factory floors. Large, easy-to-use buttons support quick calls, which is important when workers wear gloves or need to act fast.

Oil and Gas Facilities

Oil and gas facilities present some of the harshest environments. Offshore platforms and refineries require equipment that can withstand explosive atmospheres, salt spray, and extreme weather. Telephones in these locations must be explosion-proof, vandal-proof, and waterproof. These features prevent communication failures that could lead to accidents or costly downtime. Reliable voice systems support emergency response, coordination, and continuous monitoring. Compliance with safety standards like ATEX and IECEx protects workers and meets strict regulations. Operators also benefit from secure, 24/7 communication recording, which helps with incident reviews and improves safety protocols.

Note: Rugged telephones in oil and gas sites reduce downtime and maintenance costs, helping teams stay efficient and safe.

Centres de transport

Airports, rail stations, and ports rely on dependable communication to keep people and goods moving. Telephones in these hubs must resist vandalism, moisture, and temperature swings. Staff use them to report hazards, coordinate logistics, and call for help during emergencies. Clear audio and loud ringers ensure messages get through, even in crowded or noisy terminals.

Mining Sites

Mining sites challenge equipment with dust, moisture, and heavy impacts. Telephones here use aluminum alloy shells and waterproof keypads. Features like emergency SOS buttons, loud ringers, and hands-free calling support rapid response in dangerous situations. Workers can quickly reach help using speed dial keys, even underground or in remote tunnels. These systems operate reliably in temperatures from -40°C to +60°C and humidity up to 95%.

| Feature | Benefit |

|---|---|

| Waterproof Keypad | Works in wet, dusty conditions |

| Emergency Button | Fast SOS alerts |

| Loud Ringer | Audible in noisy environments |

| Hands-Free Calling | Easy use during emergencies |

Analog industrial telephones deliver dependable operation through rugged design, weather resistance, and clear audio.

- Explosion-proof models support safety in oil refineries, chemical plants, and mining.

- Manufacturers focus on durability, voice clarity, and compliance with strict regulations.

- Global demand continues to grow as industries prioritize worker safety and reliable communication.

FAQ

What makes analog industrial telephones different from regular phones?

Analog industrial telephones use rugged materials and weatherproof designs. They work in extreme environments where standard phones would fail.

Can analog industrial telephones operate during power outages?

Yes. These telephones draw power from the telephone line. They keep working even if the main power supply goes down.

How do workers use these phones in noisy areas?

Noise-canceling microphones and loud ringers help workers hear and speak clearly. The design supports communication even near heavy machinery.