Clean rooms demand strict control over contamination. Emergency handsfree telephone dust proof Industrial Intercom systems deliver instant, sterile communication. Staff use these devices to call for help or coordinate safely. A rugged emergency telephone, une auto dial emergency telephone, or a Téléphone d'urgence du trafic ensures reliable performance in hazardous conditions.

Clean Room Challenges and the Role of Emergency Handsfree Telephone Dust Proof Industrial Intercom

Unique Risks and Communication Needs in Clean Rooms

Clean rooms face unique risks that threaten both safety and product quality. Contamination can come from many sources:

- Personnel introduce skin flakes, hair, and fibers, especially if gowning protocols are not followed.

- Water purity issues can bring in unwanted particles.

- Equipment and tools may contaminate the environment if not cleaned properly.

- Chemicals and their containers can introduce impurities.

- Airflow disruptions from poorly maintained HVAC systems allow contaminants to circulate.

- Raw materials and packaging may carry dust or bacteria.

- Cleaning procedures must be thorough and regularly audited.

Personnel contribute up to 80% of particles found in clean rooms, making strict protocols and reliable communication essential for safety.

Limitations des dispositifs de communication standard

Standard communication devices do not meet clean room requirements. Cellphones, for example, are banned in many clean rooms because they introduce germs and particles. These devices often:

- Generate particles that contaminate the environment.

- Cannot withstand sterilization or disinfection.

- Lack electrostatic discharge protection, risking equipment damage.

- Are difficult to use with gloves and protective suits.

- Suffer from noise interference.

- Do not support hands-free operation.

- Lack emergency features needed in critical situations.

Importance of Immediate, Handsfree, and Dust Proof Solutions

An Interphone industrielle à preuves de téléphone éprouvantes de téléphone d'urgence addresses these challenges. Workers can communicate without removing gloves or breaking sterile protocols. Devices with smooth, sealed surfaces allow easy cleaning and resist chemicals and moisture. Hands-free operation reduces physical contact, lowering contamination risk. These features help maintain clean room sterility and support rapid emergency response.

Safety-Enhancing Features of Emergency Handsfree Telephone Dust Proof Industrial Intercom

Handsfree Operation for Sterile Environments

Opération sans mains stands as a critical feature in clean room safety. Workers can communicate without touching the device, which helps prevent the spread of contaminants. The Emergency handsfree telephone dust proof Industrial Intercom uses advanced technology to support loud-speaking communication. This design allows staff to keep gloves on and maintain sterile protocols.

| Feature | Description |

|---|---|

| Material | SUS304 stainless steel, easy to sanitize with detergents and bactericidal agents |

| Design | No gaps or holes, flush mounting, seamless surface |

| Operation | Handsfree loud-speaking communication |

| Protection | Vandal and weather resistant, IP54-IP65 waterproof protection |

| Mounting | Flush mounting with tamper-proof screws |

| Keypad | Vandal resistant, customizable |

| Certification | CE, FCC, RoHS, ISO9001 compliant |

| Application | Clean rooms, laboratories, hospital isolation, sterile areas |

Handsfree intercoms reduce cross-contamination by allowing communication without physical contact. Touchless activation, seamless surfaces, and easy-to-clean materials further support sterile environments.

Dust Proof and Hygienic Construction

Clean rooms require equipment that resists dust and supports hygiene. The Emergency handsfree telephone dust proof Industrial Intercom features a seamless, non-porous body made from corrosion-resistant stainless steel. This construction prevents dust and microbes from accumulating in crevices.

- Non-fibrous, non-static generating, and non-corrosive materials ensure easy cleaning.

- Flat, embedded surfaces avoid dust traps and allow thorough disinfection.

- Waterproof and dustproof ratings (IP54 to IP65) protect against environmental hazards.

- Compliance with ISO 14644-1 and other international standards guarantees hygienic performance.

Laboratory tests now require intercoms to pass both impact and dust ingress tests on the same unit. This method ensures that dust proof intercoms maintain their protective qualities even after physical impacts. Devices tested under these standards show greater reliability and durability than non-dust proof alternatives.

Emergency Call and Rapid Response Capabilities

Quick response during emergencies saves lives and protects products. The Emergency handsfree telephone dust proof Industrial Intercom supports rapid call initiation and clear communication.

- Single-button design enables immediate emergency calls.

- Two-way communication allows real-time updates between staff and responders.

- Audible and visual alerts notify everyone in the area.

- Integration with centralized security platforms ensures that alerts reach the right people fast.

- Automated notifications, such as texts or emails, can be sent instantly.

- Tamper alarms alert security if the unit is removed or damaged.

- ADA-compliant buttons and indicators make the system accessible to all users.

Placement stratégique and compatibility with existing systems help maximize coverage and ensure no emergency goes unnoticed.

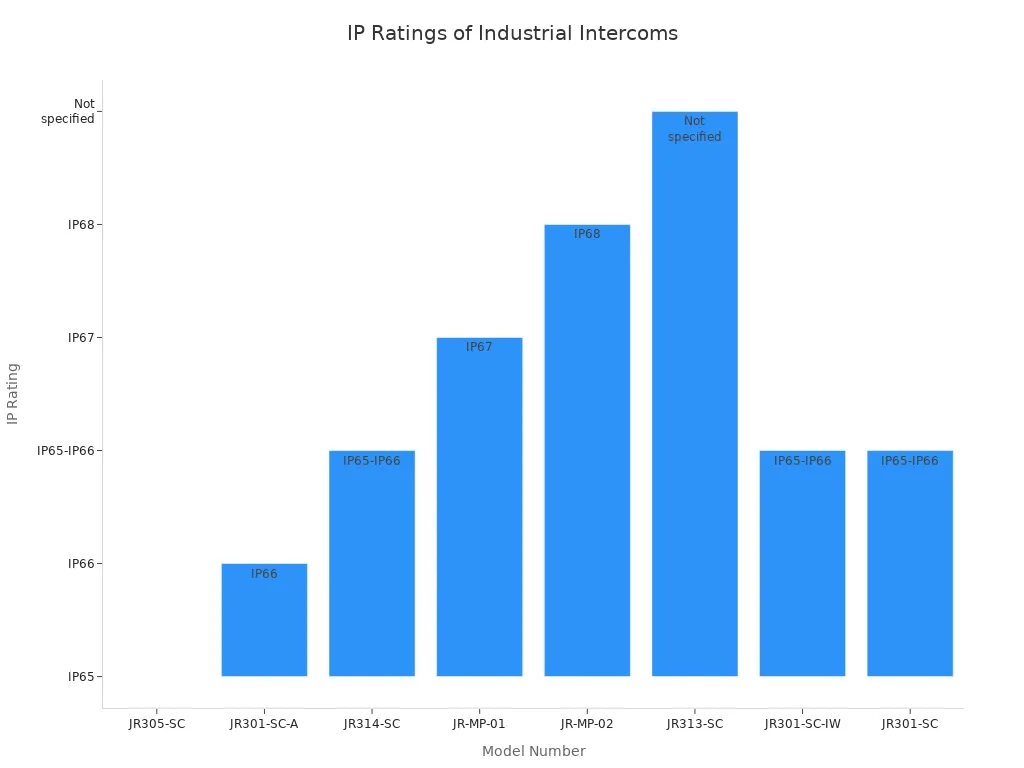

Industrial Durability and Compliance

Industrial environments demand robust equipment. The Emergency handsfree telephone dust proof Industrial Intercom meets strict durability and compliance standards.

| Model Number | Material | IP Rating | Certifications |

|---|---|---|---|

| JWAT401 | SUS304 Stainless Steel | IP54-IP65 | CE, FCC, RoHS, ISO9001 |

| JR301-SC | SUS304 Stainless Steel | IP65-IP66 | CE, FCC, RoHS, ISO9001 |

| JR305-SC | Acier à froid | IP65 | CE, FCC, RoHS, ISO9001 |

- Antimicrobial surfaces inhibit bacterial growth and resist harsh cleaning agents.

- Flat, liquid-tight designs prevent microbial buildup.

- Full-duplex communication and noise cancellation ensure clear messages, even in noisy environments.

- Minimal maintenance requirements support long-term reliability.

These features make the Emergency handsfree telephone dust proof Industrial Intercom a trusted solution for clean rooms, laboratories, and other sensitive environments.

Real-World Applications and Benefits in Clean Room Environments

Emergency Response Scenarios

Clean rooms often face emergencies such as chemical spills, equipment failures, or sudden medical incidents. Staff need to communicate quickly without leaving their workstations. The Emergency handsfree telephone dust proof Industrial Intercom provides instant, handsfree access to help. In pharmaceutical and hospital clean rooms, these intercoms support emergency evacuation and rapid coordination. The JWAT401, with its stainless steel body and noise reduction microphone, ensures clear communication even in noisy or high-risk areas. This reliability helps staff respond faster and reduces the risk of escalation.

Contamination Control and Incident Management

Contamination control remains a top priority in clean rooms. Intercoms with seamless, antibacterial surfaces allow staff to report incidents without touching shared devices. Sonicu’s clean room intercoms, for example, help maintain contamination control by enabling clear communication without physical contact. Many facilities install intercoms at pass-throughs or near windows. These systems let staff coordinate the transfer of materials or manage incidents without opening doors or entering the clean room, which helps prevent the spread of contaminants.

Tip: Place intercoms at key locations to support incident management and reduce unnecessary movement.

Opérations de routine et coordination de l'équipe

Daily operations in clean rooms require constant teamwork. Intercom systems enable staff to share updates, request supplies, or coordinate tasks without leaving their stations. In pharmacy clean rooms, seamless communication reduces errors and improves workflow. Research shows that integrating IoT and advanced connectivity into intercoms can boost operational performance by up to 30%. Staff work more efficiently and productivity increases when communication is clear and immediate.

Meeting Regulatory and Safety Standards

Clean rooms must meet strict safety and hygiene standards. Intercoms like the JWAT401 comply with international certifications such as CE, FCC, RoHS, and ISO9001. These devices support protocols that prevent both doors of a pass-through from opening at the same time, which helps control contamination. Sealed, flush-mounted designs resist bacteria and withstand harsh cleaning agents. By using compliant intercoms, facilities demonstrate their commitment to safety and regulatory requirements.

Emergency handsfree telephone dust proof Industrial Intercom systems play a vital role in clean room safety. Their sealed, antimicrobial surfaces and handsfree operation help reduce contamination and support regulatory compliance. Industry experts recommend these robust devices for reliable, hygienic communication in sensitive environments.

- Handsfree, no-touch operation maintains hygiene.

- Certified materials and protection ratings ensure durability.

FAQ

How does the JWAT401 intercom support clean room hygiene?

The JWAT401 uses a seamless stainless steel body. Staff can clean it easily with disinfectants. Its handsfree design helps reduce contamination risks.

Tip: Regular cleaning with approved agents keeps the intercom hygienic and reliable.

Can the JWAT401 intercom work in extreme environments?

Yes. The JWAT401 operates in temperatures from -40°C to +70°C. It resists humidity up to 95%. Its IP54-IP65 rating protects against dust and water.

Does the JWAT401 meet international safety standards?

The JWAT401 meets CE, FCC, RoHS, and ISO9001 certifications. Facilities can trust its compliance with global safety and quality requirements.