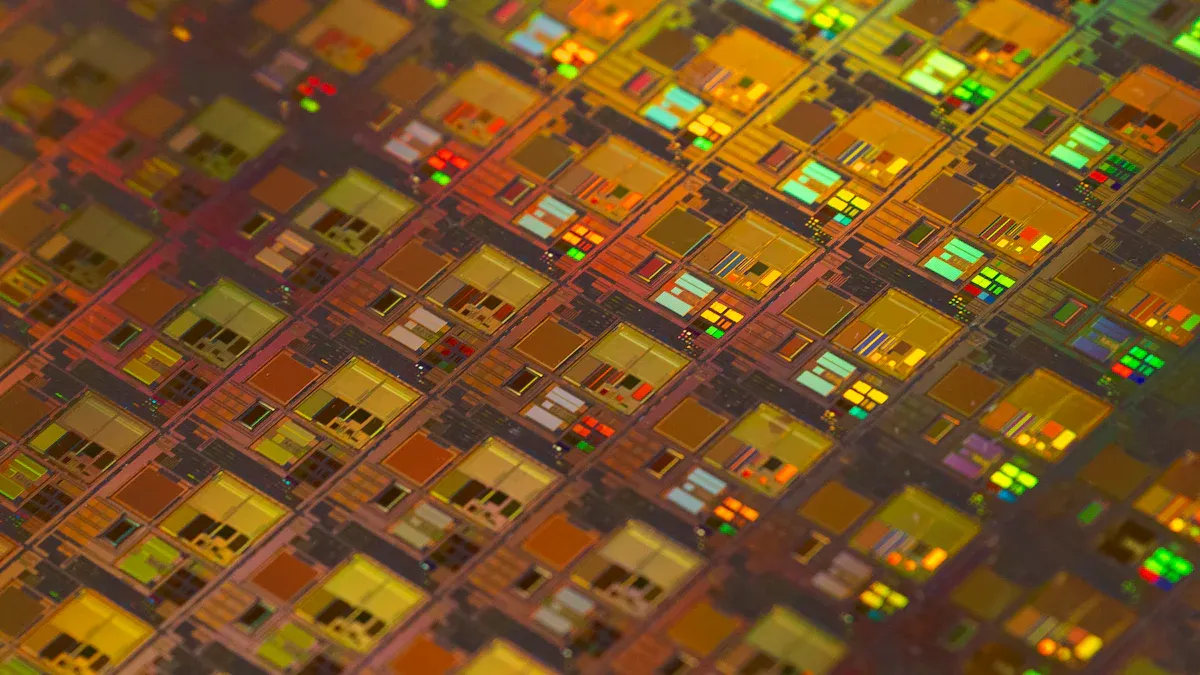

Epi wafers are thin layers of crystalline material grown on a base called a substrate. You’ll find them at the heart of modern electronics because they improve how devices perform. Their precise structure makes them essential for creating reliable semiconductors, power electronics, and sensors. By using an epitaxial wafer, engineers can design devices with better speed, efficiency, and accuracy. For advanced applications like quantum computing and optoelectronics, an epitaxial silicon wafer provides the high purity needed to push innovation forward.

Key Takeaways

- Epi wafers make electronics work better by adding a smooth, high-quality layer with fewer flaws. This improves efficiency and reliability.

- Making epi wafers uses special methods like Chemical Vapor Deposition (CVD) and Molecular Beam Epitaxy (MBE). These methods ensure even thickness and great purity.

- Epi wafers are important for advanced tech like quantum computers and optoelectronics. Their special features help create better and more innovative devices.

- Using epi wafers improves how electricity and heat move in devices. This makes gadgets faster, cooler, and last longer.

- Epi wafers can be made in large amounts. This helps companies meet the need for better electronics without losing quality.

How Are Epi Wafers Made?

Creating epi wafers involves a precise and controlled process. You might wonder how these thin crystalline layers are formed. The manufacturing process ensures the wafers meet the high standards required for modern electronics. Let’s explore the key steps and techniques used to produce them.

Overview of the Manufacturing Process

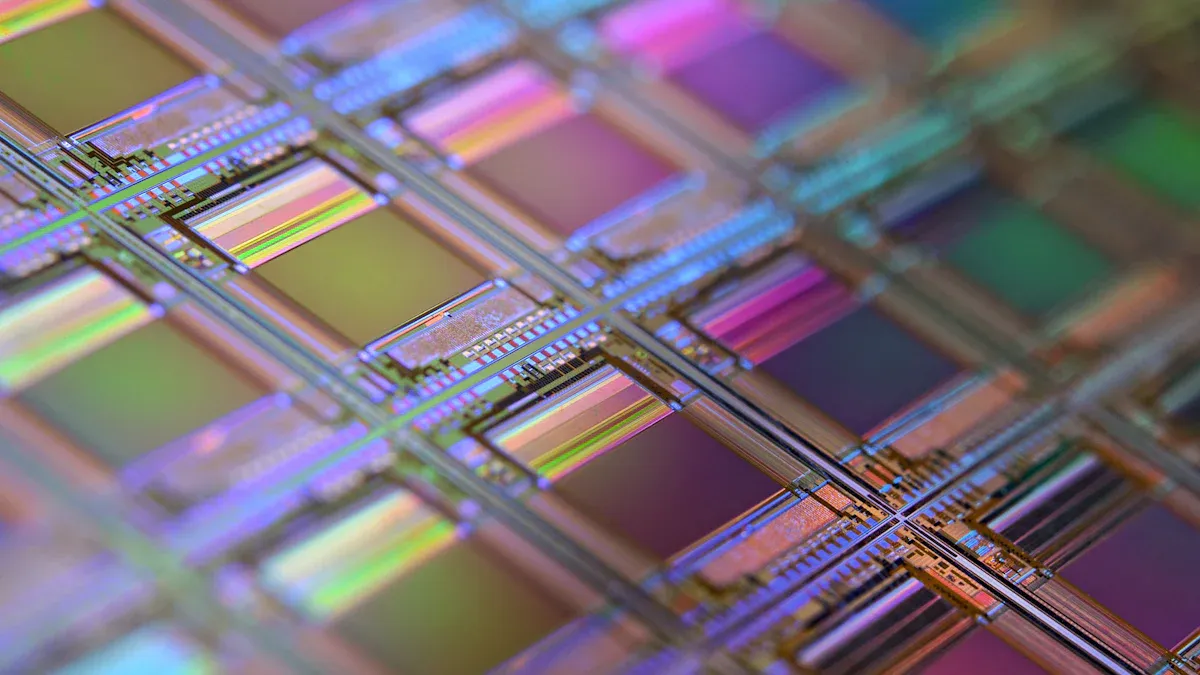

The production of epi wafers begins with a substrate, often made of silicon. This substrate acts as the foundation for the epitaxial layer. The process starts by cleaning the substrate to remove impurities. Once clean, the substrate is placed in a specialized chamber where the epitaxial layer is grown.

The growth process involves depositing a thin layer of crystalline material onto the substrate. This layer matches the crystal structure of the substrate, ensuring a seamless bond. The result is a wafer with enhanced properties, such as improved electrical conductivity and reduced defects. Two common methods used for this deposition are Chemical Vapor Deposition (CVD) and Molecular Beam Epitaxy (MBE).

Chemical Vapor Deposition (CVD)

CVD is one of the most widely used techniques for creating epi wafers. In this method, you introduce a mixture of gases into a reaction chamber. These gases contain the elements needed to form the epitaxial layer. When heated, the gases react and deposit a thin film of material onto the substrate.

This process allows for precise control over the thickness and composition of the layer. You can adjust the gas flow, temperature, and pressure to achieve the desired properties. CVD is highly efficient and suitable for producing large quantities of wafers with consistent quality.

Molecular Beam Epitaxy (MBE)

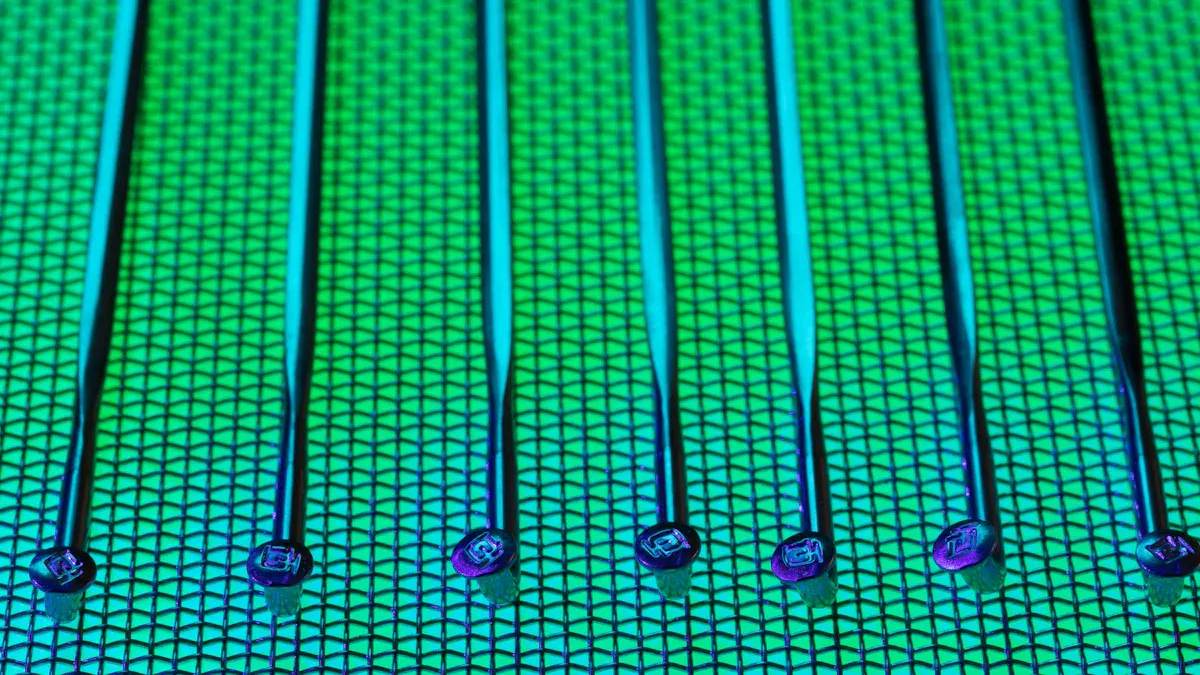

MBE is another technique used to produce epi wafers, but it operates differently from CVD. In this method, you place the substrate in a vacuum chamber. Then, beams of atoms or molecules are directed at the substrate. These particles condense on the surface, forming the epitaxial layer.

MBE offers unparalleled precision. It allows you to control the growth of the layer at the atomic level. This makes it ideal for applications requiring ultra-thin layers or complex structures. However, MBE is slower and more expensive than CVD, so it’s typically used for research or specialized devices.

Quality Control and Testing

When it comes to epi wafers, quality control and testing are critical steps in ensuring their reliability and performance. These processes help you verify that the wafers meet the strict standards required for modern electronics. Without proper testing, even minor defects could lead to device failures or reduced efficiency.

Key Quality Control Measures

To maintain high standards, manufacturers use several quality control measures during and after production. Here are some of the most important ones:

- Surface Inspection: You need to check the wafer’s surface for defects like scratches, particles, or irregularities. Advanced tools, such as optical microscopes and laser scanners, help detect even the tiniest imperfections.

- Mesure d'épaisseur: Uniform thickness is essential for epi wafers. Manufacturers use specialized instruments, like ellipsometers, to measure the thickness of the epitaxial layer with extreme precision.

- Crystallographic Analysis: The crystal structure of the epitaxial layer must align perfectly with the substrate. X-ray diffraction (XRD) is a common technique used to analyze this alignment.

Electrical and Thermal Testing

Testing the electrical and thermal properties of epi wafers ensures they perform as expected in real-world applications. These tests include:

- Resistivity Testing: This test measures how well the wafer conducts electricity. A low resistivity indicates better conductivity, which is crucial for devices like transistors and diodes.

- Carrier Lifetime Measurement: You can evaluate how long charge carriers (electrons or holes) remain active in the wafer. Longer carrier lifetimes often mean better device performance.

- Thermal Conductivity Testing: High thermal conductivity helps devices dissipate heat efficiently. This property is especially important for power electronics.

Tip: Consistent testing at every stage of production reduces the risk of defects and ensures the wafers meet industry standards.

Advanced Testing Techniques

For cutting-edge applications, you may need advanced testing methods to ensure the wafers meet specialized requirements. Some of these techniques include:

- Atomic Force Microscopy (AFM): This method provides a detailed view of the wafer’s surface at the atomic level. It helps you identify nanoscale defects that might affect performance.

- Photoluminescence Testing: By analyzing the light emitted from the wafer when exposed to a laser, you can assess its optical and electronic properties. This test is particularly useful for optoelectronic devices.

- Fourier Transform Infrared Spectroscopy (FTIR): This technique measures the chemical composition of the wafer, ensuring it contains the right materials in the correct proportions.

By combining these quality control and testing methods, manufacturers can produce epi wafers that meet the demanding requirements of modern electronics. These steps ensure the wafers deliver consistent performance, whether used in semiconductors, power devices, or advanced sensors.

Unique Properties of Epi Wafers

Low Defect Density

Epi wafers are known for their low defect density, which means they have fewer imperfections in their crystal structure. This property is crucial because defects can disrupt the flow of electricity in electronic devices. When you use a wafer with fewer defects, you get better performance and reliability. Manufacturers achieve this by carefully controlling the growth process, ensuring the epitaxial layer matches the substrate perfectly. This precision reduces the chances of defects forming during production.

Uniform Thickness

Another standout feature of epi wafers is their uniform thickness. A consistent thickness ensures that electronic devices function as intended. Variations in thickness can lead to uneven electrical properties, which might cause devices to fail. Advanced techniques like Chemical Vapor Deposition (CVD) and Molecular Beam Epitaxy (MBE) help maintain this uniformity. These methods allow you to control the growth of the epitaxial layer with incredible accuracy. As a result, you get wafers that meet the strict requirements of modern electronics.

High Purity and Precision

Epi wafers also offer high purity and precision, making them ideal for advanced applications. High purity means the material contains very few impurities, which can interfere with electrical conductivity. Precision refers to the exact control over the wafer’s composition and structure. These qualities are essential for devices like transistors, sensors, and power electronics. By using epi wafers, you can create devices that are faster, more efficient, and longer-lasting.

Note: The unique properties of epi wafers make them indispensable in the electronics industry. Their low defect density, uniform thickness, and high purity ensure they meet the demands of cutting-edge technologies.

Enhanced Electrical and Thermal Conductivity

Epi wafers stand out for their exceptional electrical and thermal conductivity. These properties play a critical role in ensuring that electronic devices operate efficiently and reliably. But what makes epi wafers so effective in this regard? Let’s break it down.

Electrical Conductivity

Epi wafers provide superior electrical conductivity due to their high purity and precise crystal structure. When you use an epi wafer, the flow of electricity becomes smoother because there are fewer impurities and defects to disrupt it. This is especially important for devices like transistors and diodes, where even a small resistance can impact performance.

- Pourquoi ça compte: Better conductivity means faster signal transmission and lower energy loss. This helps your devices run more efficiently and consume less power.

- Real-World Example: In smartphones, epi wafers enable processors to handle complex tasks without overheating or slowing down.

Tip: If you’re designing high-performance electronics, choosing materials with excellent electrical conductivity can make a big difference in speed and efficiency.

Thermal Conductivity

Thermal conductivity is another area where epi wafers excel. They can dissipate heat more effectively than standard materials. This is crucial because excessive heat can damage electronic components or reduce their lifespan.

- Comment ça marche: The uniform structure of epi wafers allows heat to spread evenly across the material. This prevents hotspots and keeps devices cooler.

- Applications: Power electronics, such as those in electric vehicles, rely on epi wafers to manage heat while delivering high power output.

Note: Devices that stay cool last longer and perform better, making thermal conductivity a key factor in modern electronics.

By enhancing both electrical and thermal conductivity, epi wafers ensure that your devices are not only faster but also more durable. These properties make them indispensable in today’s technology-driven world.

Applications of Epi Wafers in Modern Electronics

Epi wafers play a vital role in modern electronics, enabling the development of devices that are faster, more efficient, and highly reliable. Let’s explore how they are used in key applications like diodes, transistors, power electronics, and optoelectronic devices.

Diodes and Transistors

Diodes and transistors form the backbone of most electronic circuits. You’ll find them in everything from smartphones to industrial machinery. Epi wafers enhance their performance by providing a high-quality crystalline layer with fewer defects. This ensures better electrical conductivity and improved efficiency.

- Diodes: Epi wafers help create diodes with precise electrical properties. For example, in light-emitting diodes (LEDs), they improve brightness and energy efficiency.

- Transistors: In transistors, epi wafers enable faster switching speeds and lower power consumption. This is crucial for processors in computers and mobile devices.

Le saviez - vous? The use of epi wafers in transistors has been a game-changer for microprocessors, allowing them to handle billions of calculations per second.

Power Electronics

Power electronics manage and control the flow of electrical energy in devices like electric vehicles, solar inverters, and industrial equipment. Epi wafers are essential here because they can handle high voltages and currents without overheating.

- Pourquoi ça compte: Devices made with epi wafers can operate at higher temperatures and voltages, making them ideal for demanding applications.

- Real-World Example: In electric vehicles, epi wafers improve the efficiency of power converters, extending battery life and driving range.

A key advantage of epi wafers in power electronics is their ability to reduce energy loss. This makes your devices more energy-efficient and environmentally friendly.

Optoelectronic Devices

Optoelectronic devices, such as lasers, photodetectors, and solar cells, rely on epi wafers for their high precision and performance. These devices convert light into electrical signals or vice versa, and epi wafers ensure this process happens efficiently.

- Lasers: Epi wafers enable the production of lasers with consistent wavelength and intensity. This is critical for applications like fiber-optic communication and medical equipment.

- Photodetectors: In photodetectors, epi wafers improve sensitivity, allowing them to detect even the faintest light signals.

- Solar Cells: Epi wafers enhance the efficiency of solar cells by maximizing light absorption and minimizing energy loss.

Tip: If you’re exploring renewable energy solutions, consider how epi wafers contribute to the development of high-performance solar panels.

By supporting these applications, epi wafers continue to drive innovation in modern electronics. Their unique properties make them indispensable for creating devices that meet the demands of today’s technology-driven world.

Emerging Technologies, Including Quantum Computing and Advanced Sensors

Epi wafers are paving the way for groundbreaking advancements in emerging technologies. Their unique properties make them indispensable in fields like quantum computing and advanced sensors. Let’s explore how these technologies benefit from epi wafers and why they are essential for innovation.

Quantum Computing

Quantum computing represents the next frontier in technology. Unlike traditional computers that use bits to process information, quantum computers rely on quantum bits, or qubits. These qubits can exist in multiple states simultaneously, enabling quantum computers to solve complex problems much faster than conventional systems.

Epi wafers play a critical role in the development of quantum computing. They provide the high-purity materials needed to create qubits with exceptional stability and precision. For example, silicon-based epi wafers are used to fabricate quantum dots, which serve as the building blocks for qubits. Their low defect density ensures that qubits operate reliably, minimizing errors during computation.

Le saviez - vous? Quantum computers powered by epi wafers could revolutionize fields like cryptography, drug discovery, and artificial intelligence.

Capteurs avancés

Advanced sensors are transforming industries by enabling more accurate and efficient data collection. From medical diagnostics to environmental monitoring, these sensors are becoming increasingly vital in today’s world. Epi wafers enhance their performance by providing a stable and precise platform for sensor components.

- Medical Applications: In healthcare, epi wafers are used to create biosensors that detect diseases at an early stage. These sensors rely on the wafer’s high purity and uniformity to deliver accurate results.

- Environmental Monitoring: Epi wafers also improve the sensitivity of sensors used to monitor air quality, water pollution, and other environmental factors. This helps you gather reliable data to address global challenges.

- Industrial Use: In manufacturing, advanced sensors built on epi wafers ensure precise measurements, improving efficiency and reducing waste.

Tip: If you’re interested in cutting-edge technology, keep an eye on how epi wafers are driving innovation in sensor development.

Why Epi Wafers Matter

The unique properties of epi wafers, such as their low defect density and high purity, make them ideal for these emerging technologies. They enable quantum computers to perform complex calculations with minimal errors and allow sensors to operate with unmatched accuracy. As these technologies continue to evolve, epi wafers will remain at the core of their success.

By supporting advancements in quantum computing and advanced sensors, epi wafers are shaping the future of technology. Their role in these fields highlights their importance in driving innovation and solving some of the world’s most pressing challenges.

Advantages of Epi Wafers in Electronics

Improved Device Efficiency

Epi wafers improve device efficiency by enhancing electrical conductivity and reducing energy loss. When you use them in electronic components, they allow electricity to flow smoothly, minimizing resistance. This results in faster signal transmission and lower power consumption. For example, in processors, epi wafers enable quicker data processing, which boosts the performance of devices like smartphones and computers.

Another way epi wafers enhance efficiency is by optimizing thermal conductivity. They help devices dissipate heat more effectively, preventing overheating. This is especially important for power electronics, where high temperatures can reduce performance. By using epi wafers, you ensure your devices operate at peak efficiency while staying cool.

Tip: If you want to design energy-efficient electronics, consider materials like epi wafers that improve both electrical and thermal performance.

Enhanced Reliability and Longevity

Reliability and longevity are critical for electronic devices, and epi wafers play a key role in achieving both. Their low defect density ensures fewer interruptions in the flow of electricity, which reduces the risk of device failure. When you use epi wafers, your devices become more dependable, even in demanding conditions.

Epi wafers also extend the lifespan of electronic components. Their uniform thickness and high purity prevent wear and tear caused by uneven electrical or thermal properties. For instance, in electric vehicles, epi wafers help power converters last longer, reducing maintenance costs.

Le saviez - vous? Devices built with epi wafers often outlast those made with standard materials, making them a cost-effective choice for long-term use.

Scalability for Mass Production

Epi wafers are highly scalable, making them ideal for mass production. Manufacturers can produce large quantities of wafers with consistent quality, thanks to advanced techniques like Chemical Vapor Deposition (CVD). This scalability ensures that you can meet the growing demand for electronic devices without compromising performance.

The uniformity of epi wafers also simplifies the manufacturing process. When you use materials with consistent properties, it becomes easier to integrate them into production lines. This reduces costs and speeds up production, allowing you to deliver high-quality devices to the market faster.

Note: Scalability is essential for industries like consumer electronics, where demand for devices continues to rise. Epi wafers help manufacturers keep up with this demand while maintaining reliability.

Epi wafers are the foundation of modern electronics, offering unmatched precision and performance. Their low defect density, uniform thickness, and high purity make them essential for creating efficient and reliable devices. You’ll find them in everything from transistors and power electronics to advanced technologies like quantum computing and sensors. By enabling faster, more efficient, and durable devices, epi wafers continue to drive innovation. As technology evolves, their role in shaping the future of electronics will only grow.

FAQ

What is the main purpose of an epi wafer?

An epi wafer improves the performance of electronic devices. It provides a high-quality crystalline layer with fewer defects, enhancing electrical conductivity, thermal management, and overall efficiency. This makes it essential for advanced technologies like semiconductors and sensors.

How does an epi wafer differ from a regular wafer?

An epi wafer has an additional crystalline layer grown on its surface. This layer offers higher purity, uniform thickness, and better electrical properties compared to a regular wafer. These features make epi wafers ideal for high-performance electronics.

Why are epi wafers important for power electronics?

Epi wafers handle high voltages and currents efficiently. Their superior thermal conductivity prevents overheating, ensuring reliable operation in demanding applications like electric vehicles and industrial equipment. This makes them a key component in power electronics.

Can epi wafers be used in renewable energy devices?

Yes, epi wafers enhance the efficiency of renewable energy devices like solar cells. They maximize light absorption and minimize energy loss, making them ideal for creating high-performance solar panels and other green technologies.

Are epi wafers suitable for mass production?

Yes, epi wafers are scalable for mass production. Advanced manufacturing techniques like Chemical Vapor Deposition (CVD) ensure consistent quality across large quantities. This scalability supports the growing demand for modern electronic devices.

Tip: If you’re exploring advanced electronics, consider epi wafers for their unmatched precision and reliability.