Every machine has unique requirements, and the design of its interface plays a critical role in its functionality. An industrial equipment metal keypad ensures reliable performance by meeting the specific needs of your machine. Customization enhances durability and usability. For example, an industrial 4×4 metal keypad can improve efficiency in an access control system industrial metal keypad, offering both security and user satisfaction.

キーテイクアウト

- Metal keypads help machines work better and are easy to use. They are made strong to last in tough places.

- Making them fit the job is important. Change the keypad’s design, materials, and features to match how it will be used and where.

- Testing is very important. Get user opinions and check if the keypad works well in real situations to improve the design.

Understanding Industrial Equipment Metal Keypads

Definition and Purpose

An industrial equipment metal keypad serves as the interface between a machine and its user. It allows you to input commands or data, ensuring the machine operates as intended. These keypads are specifically designed for industrial environments where durability and reliability are critical. Their purpose extends beyond functionality. They also enhance user experience by providing a responsive and intuitive interface.

Key Properties and Benefits

Industrial equipment metal keypads are built to withstand harsh conditions. They resist wear and tear caused by frequent use, making them ideal for long-term applications. Their robust construction protects against environmental factors like dust, moisture, and extreme temperatures. Additionally, these keypads offer excellent tactile feedback, ensuring you can operate them efficiently even in challenging settings. Their durability reduces maintenance costs and downtime, which improves overall productivity.

Common Materials Used

The materials used in these keypads play a significant role in their performance. Stainless steel is a popular choice due to its strength and resistance to corrosion. Aluminum is another common material, valued for its lightweight properties and durability. Some keypads also incorporate silicone or rubber for sealing purposes, enhancing their resistance to water and dust. These materials ensure the keypad remains functional and reliable in demanding environments.

The Design Process for Industrial Equipment Metal Keypads

Needs Assessment and Requirements Gathering

The first step in designing an industrial equipment metal keypad involves understanding the specific needs of the machine it will serve. You must identify the machine’s operational environment, user requirements, and functional demands. For example, a keypad used in outdoor settings may need waterproofing and resistance to extreme temperatures.

To gather requirements effectively:

- Consult end-users to understand their expectations and challenges.

- Analyze the machine’s functions to determine the necessary keypad features.

- Evaluate environmental factors like exposure to dust, moisture, or chemicals.

ヒント: Create a checklist of all requirements to ensure no critical detail is overlooked during the design process.

Conceptualization and Design

Once you have the requirements, you can start conceptualizing the keypad’s design. This stage involves creating a blueprint that outlines the keypad’s layout, dimensions, and features. You should focus on making the design intuitive and user-friendly.

Key considerations during this phase include:

- Key arrangement: Ensure the layout matches the machine’s operational flow.

- Aesthetic design: Choose a style that complements the machine’s appearance.

- Ergonomics: Design the keypad for comfortable and efficient use.

You can use design software to create digital prototypes. These tools allow you to visualize the keypad and make adjustments before moving to the next stage.

Prototyping and Testing

Prototyping brings your design to life. You can create a physical model of the industrial equipment metal keypad to test its functionality and durability. This step helps you identify potential issues and refine the design.

During testing, focus on:

- Tactile feedback: Ensure the keys respond well to user input.

- 耐久性: Test the keypad under conditions similar to its intended environment.

- User experience: Gather feedback from potential users to identify areas for improvement.

Note: Testing is an iterative process. You may need to create multiple prototypes to achieve the desired results.

Material Selection and Manufacturing

Choosing the right materials is crucial for the keypad’s performance and longevity. Stainless steel and aluminum are common choices for their strength and resistance to corrosion. Silicone or rubber may be added for sealing purposes, enhancing the keypad’s resistance to water and dust.

Once you finalize the materials, you can move to the manufacturing stage. Work with a reliable manufacturer to ensure the keypad meets your specifications. Precision in manufacturing is essential to maintain quality and functionality.

Quality Assurance and Finalization

The final step involves rigorous quality assurance checks. You must ensure the industrial equipment metal keypad meets all design and performance standards. Inspect the keypad for defects, test its functionality, and verify its durability.

After passing quality checks, the keypad is ready for deployment. Document the design and testing process for future reference. This documentation can help you make improvements or troubleshoot issues later.

Customization Options for Industrial Equipment Metal Keypads

Layout and Key Configuration

The layout and key configuration of a keypad directly impact its usability. You should design the layout to match the operational flow of the machine it serves. For instance, a numeric keypad might work best for data entry tasks, while a function-based layout could suit machines requiring specific commands.

Consider the size and spacing of the keys. Larger keys with adequate spacing reduce the chances of accidental presses, especially in environments where users wear gloves. You can also customize the number of keys to include only the essential ones, simplifying the interface.

ヒント: Always test the layout with potential users to ensure it meets their needs and preferences.

Backlighting and Visibility Enhancements

Visibility plays a crucial role in the functionality of an industrial equipment metal keypad, especially in low-light or high-glare environments. Adding backlighting to the keys ensures users can operate the machine efficiently, regardless of lighting conditions.

You can choose from various backlighting options, such as LED or electroluminescent lighting. LEDs are energy-efficient and long-lasting, making them a popular choice. Additionally, you can customize the color of the backlighting to match the machine’s design or improve visibility.

Note: Consider the environment where the keypad will be used. For outdoor settings, opt for backlighting that remains visible even in bright sunlight.

Environmental Resistance and Waterproofing

Industrial environments often expose keypads to harsh conditions, including dust, moisture, and extreme temperatures. Ensuring your keypad has environmental resistance features is essential for its longevity and performance.

Waterproofing is a critical customization option. You can achieve this by using materials like silicone seals or rubber gaskets. These materials prevent water and dust from entering the keypad, protecting its internal components. Additionally, you can opt for corrosion-resistant materials like stainless steel to enhance durability.

ヒント: Look for keypads with an IP (Ingress Protection) rating. A higher IP rating indicates better resistance to environmental factors.

Security Features and Anti-Vandalism Design

Security is a top priority for many industrial applications. You can customize your keypad with features like PIN encryption or biometric authentication to enhance security. These features ensure only authorized users can operate the machine.

For public or high-risk environments, consider an anti-vandalism design. This includes using tamper-resistant screws, reinforced materials, and flush-mounted keys to prevent damage or unauthorized access.

Note: Balancing security with usability is crucial. Ensure the added features do not complicate the user experience.

Applications of Industrial Equipment Metal Keypads

Medical Devices

In the medical field, precision and reliability are essential. An industrial equipment metal keypad plays a vital role in devices like diagnostic machines, patient monitoring systems, and surgical equipment. These keypads ensure accurate data entry and seamless operation. Their durable construction withstands frequent use and exposure to cleaning agents. This makes them ideal for sterile environments.

You can also benefit from their tactile feedback, which allows healthcare professionals to operate devices efficiently, even while wearing gloves. Additionally, the customizable layouts help match the specific functions of medical devices, improving usability and reducing errors.

Industrial Automation Systems

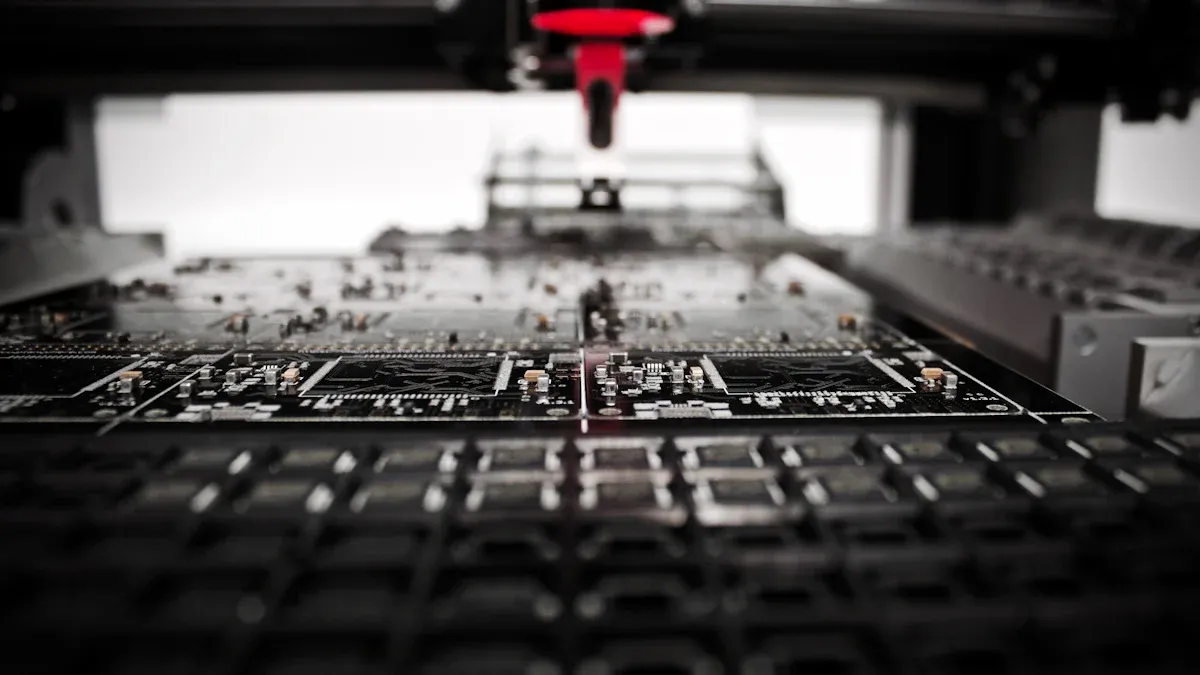

Industrial automation systems rely on robust interfaces to control machinery and processes. A well-designed industrial equipment metal keypad enhances operational efficiency in these environments. These keypads resist harsh conditions, including dust, moisture, and vibrations. This ensures consistent performance in demanding settings.

You can customize the keypad to include only the necessary keys, simplifying operations for workers. Backlighting options improve visibility in dimly lit factories, while waterproofing features protect against accidental spills. These enhancements make the keypad a reliable choice for automated systems.

Banking and Security Equipment

Banking and security equipment require keypads that prioritize both durability and security. An industrial equipment metal keypad is often used in ATMs, access control systems, and safes. These keypads are designed to resist tampering and vandalism, ensuring the safety of sensitive information and assets.

You can integrate advanced security features like PIN encryption or biometric authentication. These additions prevent unauthorized access. The sturdy materials used in these keypads also ensure long-term reliability, even in high-traffic areas.

Designing a customized industrial equipment metal keypad ensures your machine operates efficiently and reliably. Tailored designs address specific industry needs, improving usability and durability. When selecting or designing a keypad, focus on key factors like material, layout, and environmental resistance. These considerations help you create a solution that meets your machine’s unique requirements.

よくある質問

What makes metal keypads better than plastic ones?

Metal keypads offer superior durability and resistance to harsh environments. They withstand wear, moisture, and extreme temperatures, making them ideal for industrial applications.

ヒント: Choose metal keypads for long-term reliability in demanding settings.

How do I choose the right material for my keypad?

Consider the machine’s environment. Stainless steel resists corrosion, while aluminum is lightweight. Silicone or rubber enhances waterproofing and dust resistance.

Note: Match the material to your machine’s specific needs.

Can I customize the keypad for outdoor use?

Yes, you can add waterproofing, backlighting, and corrosion-resistant materials. These features ensure the keypad performs well in outdoor conditions.

Emoji Tip: 🌦️ Opt for keypads with a high IP rating for outdoor durability.