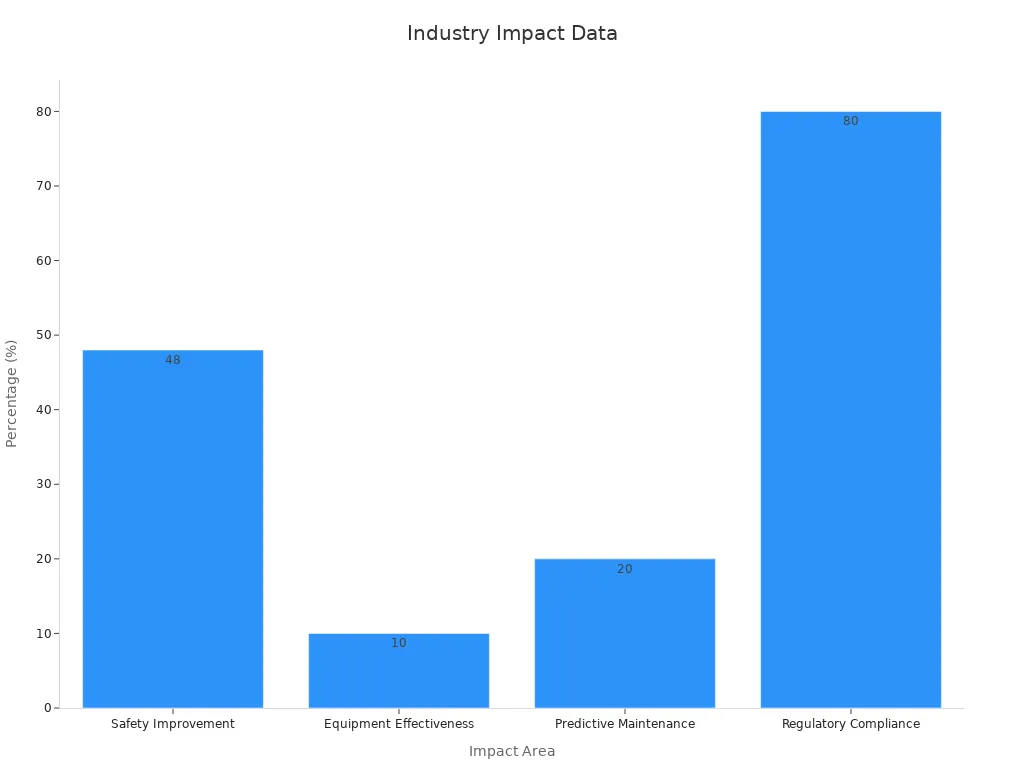

The Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810 steps up safety fast in tough places. Reliable tools like this emergency Explosion Proof Telephone keep teams connected when every second counts. As shown in the chart below, strong communication devices help lower accidents and boost compliance in oil, gas, and mining Explosion Proof Telephone sites.

Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810: Transforming Site Safety

The Importance of Robust Emergency Communication

Emergency communication saves lives in oil and gas projects. When a crisis hits, workers need to share information fast and clearly. Experts agree that strong communication systems help teams prepare for and respond to all kinds of emergencies, from fires to chemical leaks. A recent review found that good communication, teamwork, and system integration are key for emergency preparedness. These themes matter just as much in oil and gas as they do in public health. When teams can talk to each other quickly, they can manage risks and protect everyone on site.

Surveys during emergencies, like the COVID-19 pandemic, show that reliable communication helps leaders make better decisions. It also keeps everyone informed and calm. Experts say that investing in strong communication tools before a crisis builds resilience. This means sites can bounce back faster and keep people safe.

Overcoming Traditional Communication Challenges

Traditional communication systems often fall short in hazardous environments. Many oil and gas sites still face high accident rates, even with safety rules in place. The International Labor Organization reports nearly 2.78 million workplace deaths each year, with oil and gas among the highest-risk industries. Studies from countries like Malaysia, Indonesia, and China link poor communication and lack of training to unsafe behaviors and accidents.

Common problems include unclear reporting, missing information, and confusion about safety steps. These issues can lead to mistakes and injuries. Even with new technology, many sites still struggle with effective communication. Safety experts say that better communication is the key to reducing accidents and building a stronger safety culture.

- Poor communication leads to confusion and unsafe actions.

- Lack of training and unclear messages increase accident risks.

- Oil and gas sites have higher incident rates than many other industries.

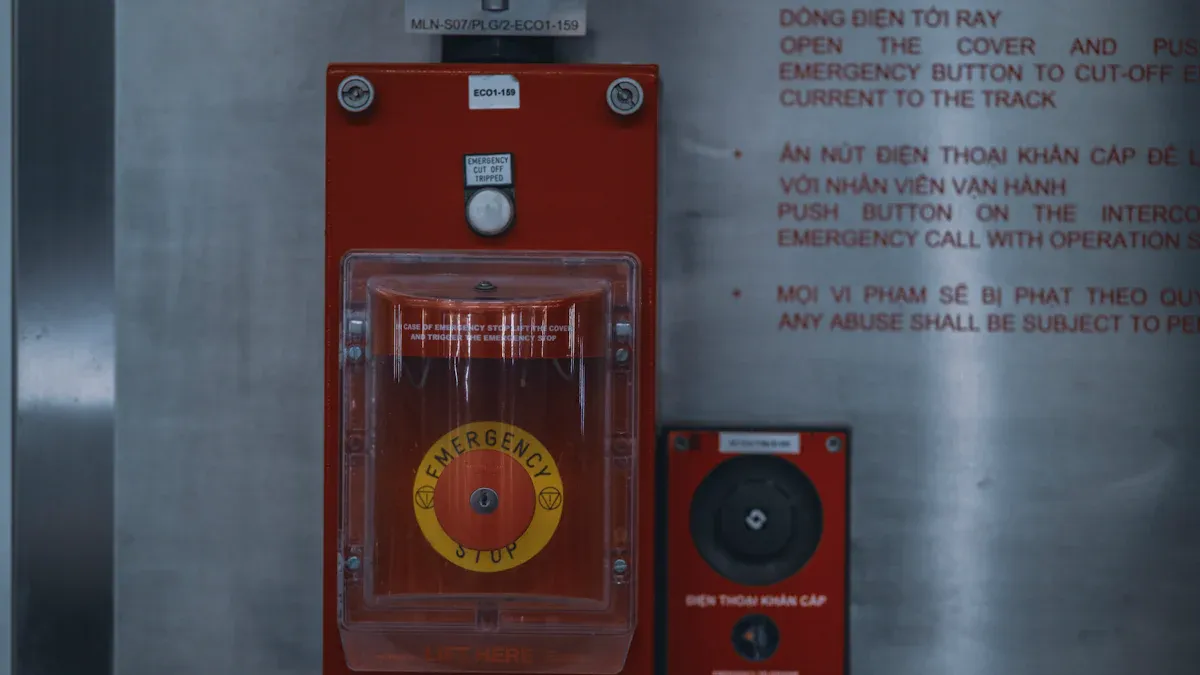

Key Features and Certifications for Hazardous Environments

The Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810 stands out because it meets strict safety standards and offers features designed for tough conditions. Here are some of the top features and certifications that make it a smart choice:

- Certified for ATEX, FCC, CE, RoHS, and ISO9001 standards.

- Explosion-proof design with strong aluminum alloy housing.

- IP68 rating for dust and water protection, even with the door open.

- Wide temperature range from -40°C to +70°C.

- Loud ringer volume over 85dB(A) for noisy environments.

- Heavy-duty handset with noise-canceling microphone.

- Multiple keypad options, including SOS and mute functions.

- Easy wall-mount installation and UV-stabilized coating for outdoor use.

Devices like the JWBT810 use low-energy circuits and sealed enclosures to prevent sparks. This means they can operate safely in places where regular phones would be dangerous. The certifications prove that the telephone can handle explosive gases, dust, and extreme weather. These features help sites meet legal requirements and keep workers safe.

- Class 1 Division 2 and IP68 ratings show the phone can survive harsh conditions.

- Explosion-proof enclosures contain any internal sparks or explosions.

- The design supports easy maintenance and long-term reliability.

Seamless Integration with Existing Safety Systems

Oil and gas sites use many different safety systems, from alarms to control rooms. The Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810 fits right in with these systems. It works as a standard analog phone, but also comes in SIP/VoIP and GSM/3G versions for modern networks. This flexibility makes it easy to connect with SCADA, DCS, and other monitoring platforms.

Case studies show that explosion-proof devices can work alongside robots, sensors, and smart controls. For example, inspection robots with explosion-proof designs help teams check equipment remotely, reducing the need for people to enter dangerous areas. These devices connect to central systems, allowing real-time updates and quick emergency responses.

- Explosion-proof phones and sensors link to SCADA and predictive maintenance systems.

- Real-time data helps teams spot problems early and act fast.

- Automated alerts and remote access support safer, more efficient operations.

A table below shows how the JWBT810 compares to traditional phones:

| Feature | JWBT810 Explosionproof Phone | Traditional Phone |

|---|---|---|

| Explosion-proof Certification | Yes | No |

| IP68 Dust/Water Protection | Yes | Limited |

| Noise-Canceling Microphone | Yes | No |

| Integration with Safety Systems | Yes | Limited |

| Wide Temperature Range | -40°C to +70°C | 0°C to 40°C |

With these advantages, the JWBT810 helps oil and gas sites improve safety, meet regulations, and keep everyone connected when it matters most.

Implementing JWBT810 for Effective Emergency Response

Site Assessment and Planning for JWBT810 Deployment

A good plan starts with a careful look at the site. Teams need to know where the biggest risks are. They should:

- Check which areas have explosive gases or dust.

- Review risks often, especially when things change.

- Add safety tools like the Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810 early in the design.

- Update plans when new machines or processes arrive.

- Watch for new rules and make changes fast.

- Use lessons from past incidents to improve safety.

- Pick equipment that keeps sparks away and protects people.

Installation and Best Practices

Installing the Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810 works best with smart choices. Many sites now use wireless systems to save time and money. Wireless setups need less wiring and can be put in place quickly. When teams use explosion-proof enclosures, they can upgrade devices without extra costs. Wired systems take longer and need more work, but both types keep people safe by using strong, sealed cases.

Staff Training for Emergency Use

Training matters. Workers learn how to use the phone in drills. They practice calling for help and sharing clear details. Good training helps everyone stay calm and act fast during real emergencies.

Maintenance, Testing, and Real-World Performance

Regular checks keep the phones working. Teams look for damage, test the sound, and make sure all parts work. They follow the maker’s guide for cleaning and repairs. Keeping records helps spot problems early. The tough build and strong metal case mean the phone stands up to harsh weather and rough use.

Measurable Benefits in Response Time and Incident Reduction

Sites see faster response times after adding these phones. Fewer accidents happen because teams can call for help right away. Reliable phones like the JWBT810 help keep everyone safe and reduce downtime.

- The Industrial Explosionproof Heavy Duty Telephone for Oil Gas Project JWBT810 boosts emergency communication and site safety.

- Teams see real value in proactive investment for explosion-proof solutions.

- Ready to improve safety? Assess your site and consider JWBT810 for reliable protection.

FAQ

How does the JWBT810 handle extreme weather?

The JWBT810 works in temperatures from -40°C to +70°C. Its IP68 rating keeps it safe from dust and water, even during storms.

Tip: The phone stays reliable in both freezing cold and blazing heat.

Can workers use the JWBT810 with gloves?

Yes, workers can press the large buttons while wearing gloves. The keypad design helps everyone make calls quickly, even in emergencies.

Does the JWBT810 connect to modern safety systems?

The JWBT810 supports analog, SIP/VoIP, and GSM/3G. It links with SCADA, DCS, and other safety platforms for smooth communication.