Reliable communication is vital in rugged environments, where extreme conditions often disrupt standard devices. For example, 43% of on-site workers report losing trust in leadership due to poor communication. The Engineer Plastic Industrial Weatherproof Telephone provides a solution. With its IP67 weatherproof telephone rating, robust engineering plastic construction, and advanced noise-canceling features, this outdoor waterproof telephone ensures uninterrupted connectivity in the harshest conditions. Additionally, the analog weatherproof telephone design makes it user-friendly and straightforward to install, further enhancing its reliability in challenging settings.

Challenges in Rugged Environments

Environmental Factors Affecting Communication

Rugged environments present unique challenges that can severely disrupt communication systems. Extreme weather conditions, such as heavy rain, snow, and high winds, often damage traditional communication devices. Dust and debris can infiltrate sensitive components, leading to malfunctions or complete failures. High humidity levels further exacerbate these issues by causing corrosion and short circuits in electronic systems.

Temperature variations also play a critical role in device performance. Many communication devices fail to operate reliably in extreme heat or cold. For instance, rugged network devices undergo rigorous thermal testing to ensure functionality in temperatures ranging from -40°C to 80°C. These tests confirm their ability to withstand harsh conditions, but traditional devices often lack such resilience. Standards like MIL-STD-180G address the impacts of humidity and dust, ensuring that rugged devices meet the demands of challenging environments.

A case study of the 2025 Los Angeles forest fires highlights the importance of reliable communication during crises. Social media responses during this event revealed significant challenges in maintaining connectivity amidst extreme weather. Public sentiment underscored the need for robust communication systems capable of withstanding such conditions.

| Aspect | Description |

|---|---|

| Focus | Analyzing social media responses to extreme weather events |

| Key Findings | Highlights unique challenges in communication during climate disasters and public sentiment |

| Case Study | 2025 Los Angeles forest fires as an example of intense online discourse during crises |

Limitations of Traditional Communication Devices

Traditional communication devices often fall short in rugged environments due to their lack of durability and adaptability. These devices are typically designed for controlled settings, making them vulnerable to environmental stressors. Exposure to water, dust, and extreme temperatures frequently leads to operational failures.

Noise interference is another significant limitation. In industrial or outdoor settings, high levels of ambient noise can render conversations inaudible. Standard devices lack advanced noise-canceling features, making them unsuitable for such conditions. Accessibility also becomes a concern, as many traditional devices do not accommodate users with hearing impairments.

The Engineer Plastic Industrial Weatherproof Telephone addresses these limitations effectively. Its robust construction and weatherproof design ensure reliable performance in harsh conditions. Features like a noise-canceling microphone and compatibility with hearing aids enhance its usability, making it a superior choice for rugged environments.

Features of Engineer Plastic Industrial Weatherproof Telephone

High-Quality Engineering Plastic Construction

The Engineer Plastic Industrial Weatherproof Telephone stands out due to its robust construction using high-quality engineering plastic. This material is specifically chosen for its exceptional durability and resistance to environmental stressors. Rigorous testing methods confirm its reliability in extreme conditions:

| Testing Method | Description |

|---|---|

| Vibration Testing | Evaluates material response to vibrational forces, assessing fatigue and structural integrity. |

| Shock Testing | Simulates extreme conditions to determine durability and energy absorption under sudden impacts. |

| High-Speed Tensile Testing | Measures tensile properties under rapid forces, revealing performance under extreme stress. |

| Environmental Testing | Assesses material reaction to environmental factors, ensuring reliability in harsh conditions. |

| Weathering Testing | Evaluates degradation under UV exposure and temperature fluctuations, crucial for outdoor applications. |

Custom extruded plastics used in the telephone resist corrosion and temperature fluctuations, ensuring long-term performance. Their impact-resistant properties protect internal components from damage during accidents or sudden impacts. This level of durability makes the device suitable for industrial and outdoor applications where reliability is critical.

Weatherproof Design and IP Ratings

The weatherproof design of the Engineer Plastic Industrial Weatherproof Telephone ensures uninterrupted communication in harsh weather conditions. Its IP ratings provide a standardized measure of protection against dust and water intrusion, making it ideal for rugged environments. Comparative studies highlight the importance of these ratings:

| IP Rating | Protection Level | Application |

|---|---|---|

| IP65 | Dust tight and protected against water jets. | Suitable for outdoor equipment exposed to rain. |

| IP66 | Dust tight and protected against powerful water jets. | Ideal for industrial environments with high moisture exposure. |

| IP67 | Dust tight and protected against immersion in water up to 1 meter. | Best for equipment that may be submerged temporarily. |

The telephone’s IP65 to IP66 rating ensures it can withstand heavy rain, high humidity, and dust-laden environments. This level of protection minimizes the risk of failure due to environmental exposure, making it a reliable choice for industries such as railways, highways, and marine settings.

Advanced Communication Features for Noise and Accessibility

The Engineer Plastic Industrial Weatherproof Telephone incorporates advanced features to enhance communication clarity and accessibility. Its noise-canceling microphone significantly reduces ambient noise, ensuring clear conversations even in loud industrial settings. Laboratory results and field tests validate the effectiveness of these features:

| Feature Type | Laboratory Efficacy | Real-World Effectiveness |

|---|---|---|

| DM/NR Features vs No Features | Robust improvement in both settings | Consistent satisfaction reported with DM/NR features |

Additionally, the telephone is compatible with hearing aids, making it accessible to users with hearing impairments. The waterproof zinc alloy keypad includes programmable function keys for speed dial, redial, and mute options, allowing users to customize their communication experience. These features collectively ensure that the device meets the demands of diverse users in challenging environments.

Applications of Engineer Plastic Industrial Weatherproof Telephone

Industrial and Outdoor Settings

The Engineer Plastic Industrial Weatherproof Telephone excels in industrial and outdoor environments where durability and reliability are paramount. Its robust engineering plastic construction and weatherproof design make it suitable for industries such as railways, highways, marine operations, and power plants. These settings often expose communication devices to extreme weather, dust, and vibrations, which can compromise functionality.

The telephone’s IP65 to IP66 rating ensures protection against water jets and dust, making it ideal for outdoor installations. For example, railways require communication systems that can withstand heavy rain and vibrations from passing trains. Similarly, marine environments demand devices resistant to saltwater corrosion and high humidity. The material properties of engineering plastics, such as FEP and PFA, further enhance the device’s performance:

| Material | Key Properties | Applications |

|---|---|---|

| FEP | Outstanding electrical properties, UV resistance, low dielectric constant | Electric wire insulation, data communication cables |

| PFA | High dielectric strength, excellent weather resistance | Flexible tubing, fluid processing equipment |

| Nylon | Strong, stiff, good chemical resistance | Aerospace and defense components, handles, tubing |

These materials ensure the telephone’s resilience in diverse industrial applications, providing uninterrupted communication even in challenging conditions.

Emergency and Safety Scenarios

Emergency situations demand reliable communication systems to coordinate responses effectively. The Engineer Plastic Industrial Weatherproof Telephone plays a critical role in such scenarios, offering features that ensure clarity and accessibility during crises. Its noise-canceling microphone and compatibility with hearing aids make it suitable for environments with high ambient noise or diverse user needs.

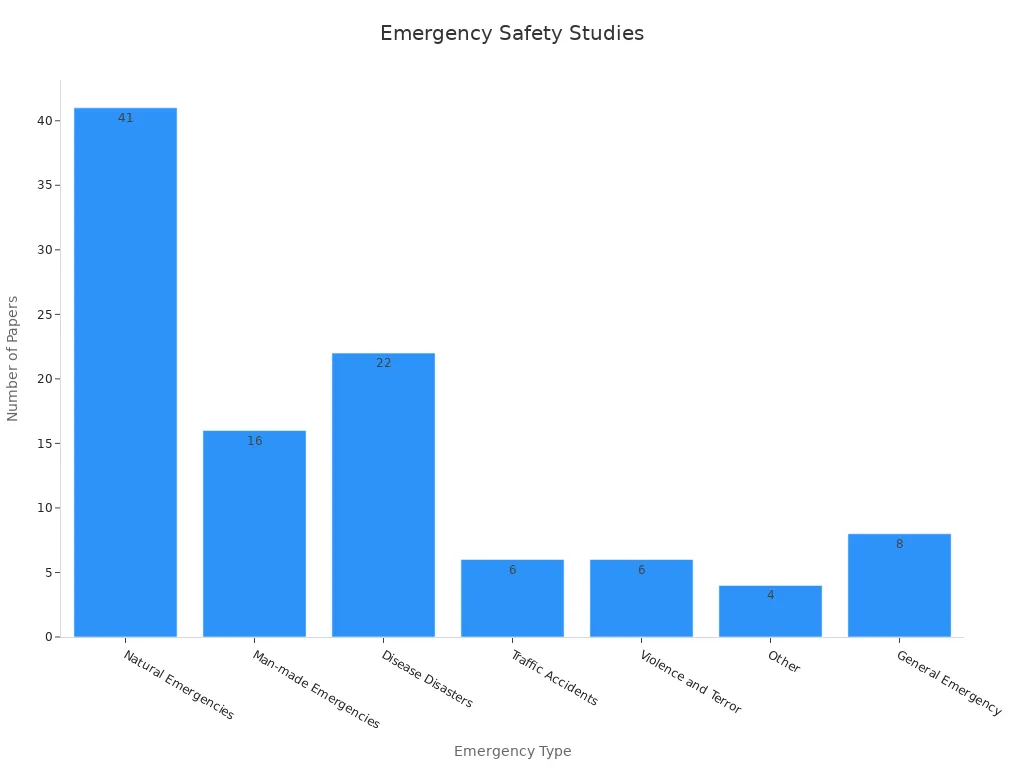

Studies on emergency response records highlight the importance of robust communication devices in various emergencies:

| Type of Emergency | Number of Papers |

|---|---|

| Natural Emergencies | 41 |

| Man-made Emergencies | 16 |

| Disease Disasters | 22 |

| Traffic Accidents | 6 |

| Violence and Terror | 6 |

| Other | 4 |

| General Emergency | 8 |

Protocols for emergency communication emphasize the need for devices that can handle urgent calls and guide unlicensed staff effectively. The telephone’s programmable function keys allow users to quickly access emergency contacts or mute calls when necessary. Its rugged design ensures functionality in extreme conditions, such as natural disasters or industrial accidents, making it an indispensable tool for safety and emergency response teams.

Reliable communication remains a cornerstone of safety and efficiency in rugged environments. The Engineer Plastic Industrial Weatherproof Telephone offers a dependable solution with its durable construction, weatherproof design, and advanced features. Its ability to perform under extreme conditions makes it an essential tool for industries and emergency scenarios. Organizations seeking robust communication systems should explore this device to ensure uninterrupted connectivity in challenging settings.

FAQ

What makes the Engineer Plastic Industrial Weatherproof Telephone unique?

The telephone combines high-quality engineering plastic, IP65-IP66 weatherproofing, and advanced noise-canceling features. These attributes ensure durability and clear communication in rugged environments.

Can the telephone operate in extreme temperatures?

Yes, the device functions reliably between -40°C and +60°C. Its robust construction ensures performance in both freezing and scorching conditions.

Is the telephone suitable for emergency scenarios?

Absolutely! Its programmable keys, noise-canceling microphone, and compatibility with hearing aids make it ideal for emergencies, ensuring quick and clear communication during critical situations.