Underground mining comes with unique hazards, and safe communication is vital. A mining Explosion Proof Telephone ensures workers stay connected without risking ignition in volatile environments. Devices like the IP Explosion Proof Telephone or the ATEX Explosion Proof Telephone provide reliable solutions. In emergencies, an emergency Explosion Proof Telephone can mean the difference between life and death.

The Risks of Underground Mining

Explosive Gases and Flammable Dust

Underground mining environments are inherently dangerous due to the presence of explosive gases like methane and flammable dust particles. These substances can ignite with even the smallest spark, leading to catastrophic explosions. Miners work in confined spaces where ventilation is often limited, increasing the risk of gas accumulation. This makes it critical to use equipment that minimizes ignition risks.

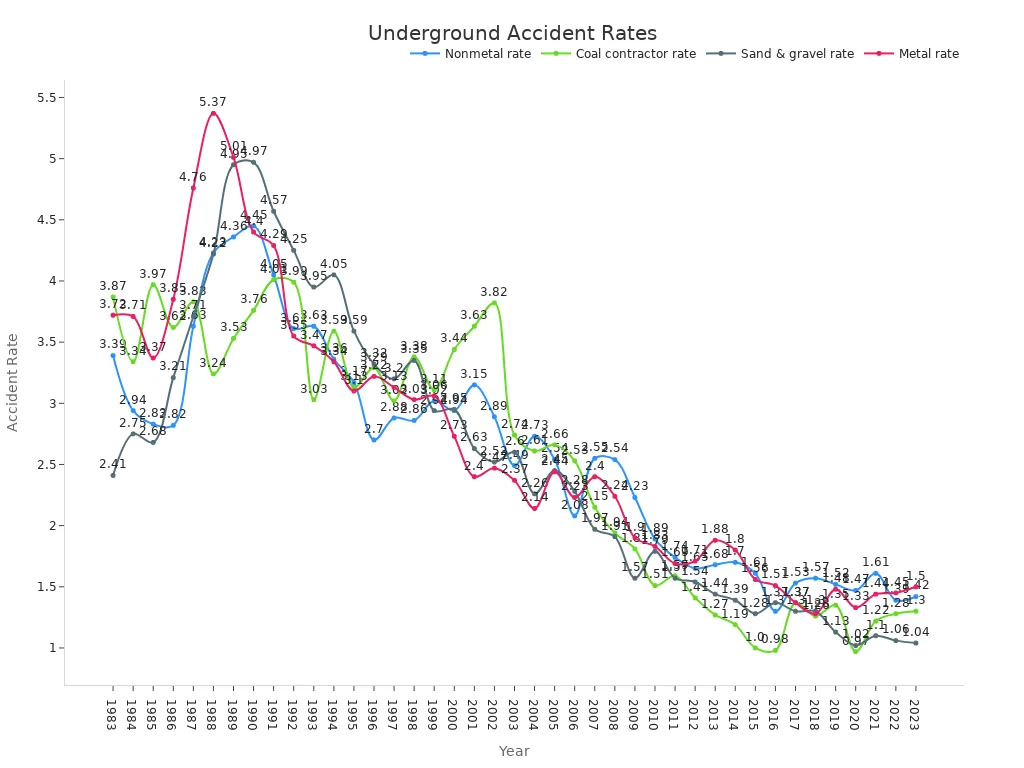

Over the years, accident rates in underground mining have shown a decline, but the dangers remain significant. For instance, the coal contractor sector has seen a reduction in accident rates from 3.87 in 1983 to 1.30 in 2023. However, these numbers highlight the ongoing need for stringent safety measures.

Explosion-proof telephones play a vital role in mitigating these risks. Their design ensures that they can operate safely in hazardous environments without triggering an explosion. This makes them an essential tool for maintaining safety underground.

Communication Challenges in Remote Locations

Mining operations often take place in remote and isolated areas, far from reliable communication networks. Underground tunnels and thick rock layers can block signals, making it difficult for miners to stay connected. In emergencies, this lack of communication can delay rescue efforts and increase the risk of injuries.

Explosion-proof telephones address these challenges by providing a robust and reliable communication system. They are designed to function in extreme conditions, ensuring that miners can communicate effectively, even in the most remote locations. This connectivity not only enhances safety but also improves operational efficiency by enabling seamless coordination among teams.

Mining Explosion Proof Telephone: What It Is and Why It Matters

Definition and Purpose

A mining Explosion Proof Telephone is a specialized communication device designed to operate safely in hazardous environments, such as underground mines. These environments often contain explosive gases or flammable dust, making standard communication equipment a potential ignition source. Explosion-proof telephones eliminate this risk by using advanced engineering to prevent sparks or heat that could ignite the surrounding atmosphere.

The primary purpose of these devices is to ensure reliable communication in areas where safety is paramount. In mining operations, clear and uninterrupted communication can save lives. Whether it’s coordinating daily tasks or responding to emergencies, these telephones provide a lifeline for workers. They are not just tools; they are essential safety measures that help maintain operational efficiency while protecting lives.

Mining Explosion Proof Telephones are also built to withstand the harsh conditions of underground environments. Their rugged design ensures durability against physical impacts, extreme temperatures, and moisture. This makes them a long-term investment for mining companies aiming to prioritize safety and reliability.

How It Operates Safely in Hazardous Environments

The safe operation of a mining Explosion Proof Telephone lies in its design and compliance with strict safety standards. These devices are engineered to be intrinsically safe, meaning they are incapable of releasing enough energy to ignite explosive gases or dust. This is achieved through features like electrical segregation, controlled system voltage, and robust insulation.

Explosion-proof telephones undergo rigorous testing to ensure their safety in hazardous conditions. Certified laboratories simulate explosive environments to evaluate the equipment’s resilience. These tests include:

- Thermal endurance to assess performance under extreme temperatures.

- Impact resistance to ensure durability against physical shocks.

- Ingress protection to prevent dust and moisture from entering the device.

For example, the MSHA (Mine Safety and Health Administration) guidelines specify conditions under which longwall face telephone systems can be deemed intrinsically safe. These include strict requirements for electrical design and adherence to safety regulations. Meeting these standards ensures that the equipment operates reliably without posing any risk to the environment.

In addition to their safety features, these telephones are designed for ease of use. Large buttons, clear audio quality, and compatibility with other communication systems make them practical for miners working in challenging conditions. By combining safety with functionality, mining Explosion Proof Telephones play a critical role in maintaining a secure and efficient mining operation.

Key Features of Mining Explosion Proof Telephone

Tamper Resistance and Durability

Mining explosion-proof telephones are built to endure the harshest conditions. Underground mines expose equipment to dust, moisture, and physical impacts daily. These telephones are designed to resist tampering and maintain functionality even in extreme environments. Their rugged construction ensures they can handle rough handling, accidental drops, and exposure to abrasive materials.

To measure their durability, manufacturers conduct rigorous tests. For instance, the MIL-STD-810H Dust/Sand test evaluates how well the device resists dust and sand particles. The MIL-STD-810H Drop test checks its shock resistance by dropping it from a height of four feet. Additionally, the FIPS 140-2 Level 3 standard ensures the telephone is tamper-resistant and secure. These tests confirm that explosion-proof telephones can withstand the challenges of underground mining.

| Test Type | Description |

|---|---|

| MIL-STD-810H Dust/Sand | Tests ingress of dust and sand particles under specific conditions to assess durability. |

| MIL-STD-810H Drop | Measures shock resistance through a series of drop tests from a height of 4 feet. |

| FIPS 140-2 Level 3 | Establishes requirements for physical tamper-resistance and identity-based authentication. |

Compliance with Safety Standards

Safety is non-negotiable in mining. Explosion-proof telephones adhere to strict safety regulations to ensure they operate without causing hazards. These devices are engineered to prevent sparks or heat that could ignite flammable gases or dust. By meeting industry standards, they provide reliable communication while protecting workers.

Industrial explosion-proof telephones are essential in hazardous environments like mines. They ensure operational continuity and worker safety by combining advanced engineering with compliance. This makes them a critical investment for any mining operation prioritizing safety and efficiency.

Enhancing Mining Safety with Explosion Proof Telephones

Emergency Communication During Crises

In underground mining, emergencies can escalate quickly. Explosions, cave-ins, or equipment failures can leave workers in life-threatening situations. During such crises, communication becomes the most critical tool for saving lives. Explosion-proof telephones provide a reliable lifeline in these moments. Their robust design ensures they function even in the harshest conditions, allowing miners to call for help or coordinate rescue efforts without delay.

These telephones are built with non-sparking materials and sealed components, making them safe to use in explosive atmospheres. This design minimizes the risk of ignition, ensuring that communication remains uninterrupted when it matters most. For instance, if a methane gas leak occurs, miners can use these devices to alert their team and evacuate the area safely. Without this immediate communication, the consequences could be catastrophic.

Moreover, explosion-proof telephones are often integrated into broader emergency response systems. They connect directly to control rooms or emergency services, enabling swift action. This seamless connectivity ensures that help arrives as quickly as possible, reducing the impact of accidents and protecting workers. In mining, where every second counts, these devices play a vital role in crisis management.

Tip: Reliable communication during emergencies isn’t just a convenience—it’s a necessity. Explosion-proof telephones ensure that miners can always reach out for help, even in the most dangerous situations.

Accident Prevention Through Reliable Connectivity

Accidents in mining often stem from miscommunication or delays in relaying critical information. Reliable connectivity provided by explosion-proof telephones helps prevent these issues. These devices enable clear and consistent communication between teams, ensuring that everyone stays informed and coordinated.

For example, if a worker detects a potential hazard, such as unstable rock formations or equipment malfunctions, they can immediately report it using a mining Explosion Proof Telephone. This quick exchange of information allows supervisors to take preventive measures, such as halting operations or rerouting workers to safer areas. By addressing risks early, mining operations can avoid accidents and maintain a safer work environment.

Explosion-proof telephones also enhance operational efficiency. They allow teams to stay connected across vast underground networks, ensuring smooth coordination. This connectivity reduces misunderstandings and streamlines decision-making, which is crucial for maintaining safety standards.

- Key Benefits of Reliable Connectivity in Mining:

- Accident Prevention: Early reporting of hazards minimizes risks.

- Operational Efficiency: Seamless communication improves teamwork.

- Compliance with Safety Standards: Reliable systems meet regulatory requirements.

The necessity of explosion-proof telephones in hazardous workplaces cannot be overstated. Their ability to function in explosive atmospheres ensures that communication remains uninterrupted, even during critical situations. By equipping mining teams with these devices, organizations can significantly reduce the likelihood of accidents and create a safer work environment.

Note: Reliable communication isn’t just about efficiency—it’s about saving lives. Mining Explosion Proof Telephones ensure that workers can stay connected, no matter the conditions underground.

Compliance and Industry Standards

Importance of Adhering to Safety Regulations

Safety regulations in mining aren’t just guidelines—they’re lifesavers. Adhering to these rules ensures that workers operate in environments designed to minimize risks. Non-compliance often leads to accidents, which can have devastating consequences for miners and their families.

Several factors highlight the importance of compliance:

- Occupational health legislation protects miners from hazardous conditions.

- Accessible safety policies and training shape miners’ understanding of compliance.

- A strong safety culture promotes adherence to regulations.

- Non-compliance remains a leading cause of mining accidents.

When mining companies prioritize compliance, they create safer workplaces. For example, training programs that teach evacuation routes and emergency response procedures significantly reduce risks. By fostering a culture of safety, organizations not only protect their workers but also enhance operational efficiency.

Certifications Required for Explosion-Proof Equipment

Certifications for explosion-proof equipment ensure that devices meet stringent safety standards. These certifications verify that equipment can operate safely in hazardous environments without causing ignition. For mining Explosion Proof Telephones, certifications are essential to guarantee reliability and safety.

| Certification | Purpose |

|---|---|

| ATEX | Ensures equipment safety in explosive atmospheres. |

| IECEx | Confirms compliance with international safety standards. |

| MSHA | Validates equipment for use in U.S. mining operations. |

Regulatory reforms like the MINER Act have strengthened certification requirements. This act mandates updated accident response plans and enhanced rescue teams. Tougher penalties for violations further emphasize the importance of compliance. By meeting certification standards, mining companies demonstrate their commitment to worker safety and regulatory adherence.

Certifications aren’t just technicalities—they’re vital for protecting lives and maintaining trust in the industry.

Explosion-proof telephones play a crucial role in underground mining. They ensure reliable communication in hazardous environments, helping to prevent accidents and save lives. As technology evolves, these devices will become even more advanced. Their continued development will shape the future of mining safety, making operations safer and more efficient.

FAQ

What makes explosion-proof telephones different from regular telephones?

Explosion-proof telephones are designed to prevent sparks or heat that could ignite gases or dust. They’re built for hazardous environments like mines, ensuring safety and reliability.

Can explosion-proof telephones work during power outages?

Yes! Many models include backup power systems or battery options. This ensures uninterrupted communication, even when the main power supply fails.

Are explosion-proof telephones hard to install?

Not at all. Manufacturers provide clear instructions, and many devices come pre-configured. Professional installation services are also available for complex setups.

Tip: Always consult the user manual or a certified technician for proper installation.