A rainproof weatherproof telephone delivers dependable communication where rain, moisture, and dust threaten standard devices. Models like the analog weatherproof telephone and IP weatherproof telephone withstand extreme temperatures and resist corrosion. Offshore weatherproof telephone solutions excel in marine environments, reducing failures and minimizing maintenance even in harsh conditions.

Rainproof Weatherproof Telephone Features

Waterproof and Dustproof Construction

A rainproof weatherproof telephone must keep out water and dust to work reliably in harsh environments. Manufacturers use the IP (Ingress Protection) rating system, defined by EN 60529, to show how well a device resists these elements. The IP rating uses two numbers: the first shows protection against solids like dust, and the second shows protection against liquids such as water. For example, an IP67 rating means the device is completely dust-tight and can survive being underwater up to 1 meter for 30 minutes. This system replaces unclear terms like “waterproof” with clear, tested standards.

| First Digit | Solid Protection Description | Second Digit | Liquid Protection Description |

|---|---|---|---|

| 0 | No protection | 0 | No protection |

| 1 | > 50 mm objects | 1 | Dripping water |

| 2 | > 12.5 mm objects | 2 | Dripping water (tilted) |

| 3 | > 2.5 mm objects | 3 | Spraying water |

| 4 | > 1.0 mm objects | 4 | Splashing water |

| 5 | Dust protected | 5 | Low-pressure water jets |

| 6 | Dust tight | 6 | High-pressure water jets |

| N/A | N/A | 7 | Immersion up to 1m |

| N/A | N/A | 8 | Immersion beyond 1m |

Most rainproof weatherproof telephones achieve IP65, IP66, or IP67 ratings. These ratings mean the devices can handle dust, rain, and even temporary submersion. The table below shows typical ratings and their uses:

| IP Rating | Dust Protection | Water Protection Description | Typical Use Case for Rainproof Weatherproof Telephones |

|---|---|---|---|

| IP65 | Total dust ingress | Protection against low-pressure water jets from any direction | Suitable for outdoor use without extreme water exposure |

| IP66 | Total dust ingress | Protection against high-pressure water jets | Suitable for harsher outdoor conditions with stronger water jets |

| IP67 | Total dust ingress | Protection against temporary immersion up to 1 meter for 30 min | Suitable for outdoor use with potential temporary water immersion |

Durable Materials and Corrosion Resistance

Manufacturers build rainproof weatherproof telephones with strong, corrosion-resistant materials. These materials include aluminum alloy, stainless steel, cold rolled steel, and engineering plastics. Aluminum alloy enclosures provide strength and resist explosions. Stainless steel parts add extra protection against rust and chemical damage. Engineering plastics offer high mechanical strength and impact resistance, helping the device achieve high IP ratings.

- Aluminum alloy and stainless steel resist corrosion and physical impacts.

- Cold rolled steel and plastic spray layers add durability.

- Engineering plastics provide strong impact resistance and help reach IP67 protection.

Note: The enclosure often includes a protective door to keep out dust and moisture, making the telephone reliable even in tough industrial settings.

To prove corrosion resistance, manufacturers test enclosures in labs. Tests include salt spray and exposure to chemicals, simulating years of harsh weather or industrial chemicals. These tests ensure the enclosure does not rust or break down, even after long exposure. Certifications like UL 50 and NEMA 6 confirm the enclosure’s ability to withstand submersion, freezing, and corrosive environments.

Vandal-Resistant and Protective Enclosures

A rainproof weatherproof telephone must also resist vandalism and tampering. Designers use reinforced materials, such as cast aluminum and stainless steel, to make the enclosure tough. The handset and cord are often armored to prevent cutting or pulling. Tamper-proof screws and lockable latches stop unauthorized access. Some models include anti-tamper designs and sealed components for extra security.

- Vandal-resistant handset and armored cord

- Corrosion-resistant cast aluminum or stainless steel case

- Tamper-proof screws and lockable latches

- High IP ratings (IP66/IP67) for outdoor protection

Protective enclosures do more than just stop vandals. They also reduce maintenance costs and downtime. The table below shows how these features improve performance:

| Metric / Feature | Impact / Improvement |

|---|---|

| Maintenance Costs | Reduced by up to 25% |

| Equipment Uptime | Improved by 20% |

| Mean Time to Repair (MTTR) | Reduced from 4.8 hours to 3.1 hours |

| Maintenance Response Time | Improved by 40% |

| Manual Triage Time | Reduced by 58% |

| Early Fault Detection | Improved by 65% |

| Operational Reliability | Increased by 25% |

Smart monitoring and rugged construction help prevent damage from weather, theft, and vandalism. These features extend the life of the telephone and keep communication lines open.

Reliable Performance in Extreme Conditions

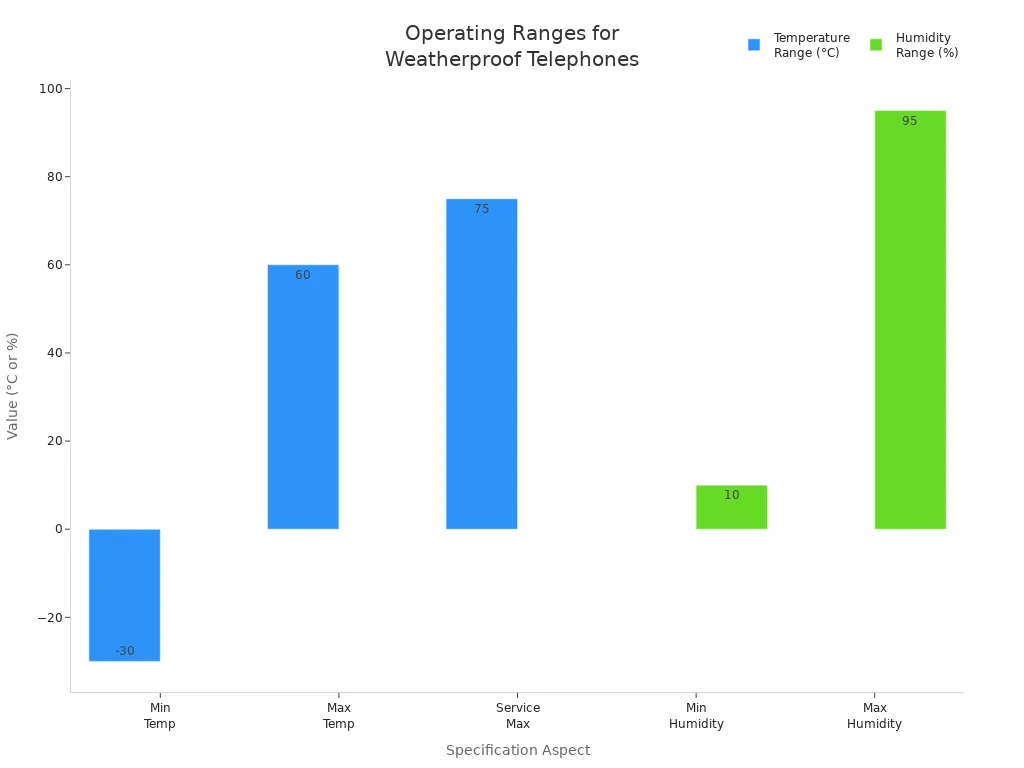

Rainproof weatherproof telephones must work in extreme temperatures and high humidity. Manufacturers design these devices to operate from -40°C to +70°C, with some models handling up to +75°C. They also work in humidity levels up to 95%. The chart below shows typical operating ranges:

Standard telephones often fail when exposed to rain and dust. Water and dust can enter the device and damage sensitive parts. Rainproof weatherproof telephones solve this problem with tight-fitting parts, rubber gaskets, and sealed enclosures. These features keep out moisture and dust, protecting the internal electronics.

The robust design leads to a much higher mean time between failures (MTBF). Some industrial models reach an MTBF of 50,000 hours, far surpassing conventional telephones. This high reliability means fewer repairs and less downtime, which is critical in emergency and industrial settings.

Rainproof Weatherproof Telephone Applications

Industrial Sites and Factories

Industrial environments demand robust communication solutions. Manufacturing facilities, mining operations, oil rigs, and power stations all face harsh conditions such as dust, vibration, temperature extremes, and chemical exposure. A rainproof weatherproof telephone provides reliable communication in these settings, even when standard devices fail.

- Manufacturing facilities require telephones that withstand dust, vibration, and rough handling.

- Mining and oil rigs depend on dustproof and explosion-proof phones for safe operation.

- Power and utility stations use weather-sealed devices to resist pollutants and weather changes.

These telephones play a critical role in maintaining safety and operational efficiency. The following table highlights how their features support safety compliance in factories and industrial sites:

| Feature/Aspect | Description/Benefit |

|---|---|

| Environmental Protection | IP67/IP68 waterproof and dustproof rating ensures telephones function reliably in harsh conditions. |

| Material Durability | Aluminum alloy die-casting shell provides high mechanical strength and impact resistance. |

| Audio Quality | Noise-canceling microphone and hearing aid compatible receiver improve communication clarity. |

| Audible Alerts | Loud ringer volume (>80dB) ensures calls are noticed even in noisy industrial settings. |

| Regulatory Compliance | Certifications including CE, FCC, RoHS, ISO9001 support adherence to safety and quality standards. |

| Operational Range | Wide temperature tolerance (-40 to +60°C) and high humidity resistance (up to 95%) ensure functionality. |

| Installation and Use | Wall-mounted design with waterproof keypad and armored cords enhances durability and ease of use. |

Tip: Industrial VoIP telephones can further improve communication efficiency and support emergency call functions, which are vital for safety and coordination.

Tunnels and Underground Facilities

Tunnels and underground spaces present unique communication challenges. Confined spaces, long distances, and physical barriers make signal transmission difficult. Environmental hazards such as water seepage, dust, toxic gases, and fire risks increase the need for reliable communication.

A rainproof weatherproof telephone addresses these challenges with rugged construction and advanced features. The table below shows how these devices solve common problems in tunnels:

| Communication Challenge in Tunnels/Underground | How Rainproof Weatherproof Telephones Address It |

|---|---|

| Confined spaces, long distances, and barriers | Rugged design ensures reliable operation despite harsh conditions |

| Water seepage, dust, toxic gases, fire risks | IP67 waterproof and dustproof rating maintains functionality in wet and dusty environments |

| Noise from machinery and alarms | Noise-canceling microphones and hearing aid-compatible receivers provide clear audio |

| Operation with gloves or in emergencies | Large, waterproof buttons and simple interface enable easy use |

| Need for quick emergency communication | Speed dial, hotline, auto answer, and high ringer volume ensure fast calls |

| Low-light or smoky conditions | Warning lights and high visibility design improve phone location |

Installation guidelines recommend sealing and securing these telephones to maintain durability. Regular testing ensures reliable operation during emergencies. While no specific regulations mandate their use, best practices and international safety standards support their integration with warning lights and loudspeakers for enhanced emergency response.

Outdoor Public Areas and Transportation Hubs

Outdoor public spaces and transportation hubs such as railways, highways, airports, and bus stations require communication devices that withstand weather and heavy use. A rainproof weatherproof telephone features a durable, waterproof shell and robust construction to resist rain, snow, and extreme temperatures.

These telephones maintain uninterrupted communication during emergencies. Speed-dial functions connect users quickly to emergency services. Noise-canceling microphones and powerful speakers ensure clear conversations, even in noisy environments. Their reliability makes them essential for public safety and emergency response, providing a dependable lifeline when needed most.

Note: In transportation hubs, these telephones often integrate with public address and emergency systems, supporting rapid evacuation and coordinated response.

Marine and Coastal Installations

Marine and coastal environments expose equipment to saltwater, humidity, UV radiation, high winds, and constant vibration. These harsh conditions can quickly damage standard communication devices. A rainproof weatherproof telephone uses corrosion-resistant materials and waterproof enclosures to ensure reliable operation.

- Exposure to saltwater corrosion and high humidity requires moisture-resistant devices.

- Continuous UV radiation and high winds demand durable construction.

- Water impacts and constant vibration test the strength of every component.

Ships, offshore oil rigs, and coastal facilities rely on these telephones for safety and operational efficiency. Wireless telephone systems with IP67+ ratings protect against water, dust, and temperature changes. Explosion-proof models serve hazardous areas like oil rigs and refineries. Integration with satellite connectivity and emergency systems ensures communication remains possible, even in remote or volatile locations.

Emergency and Safety Installations

Emergency and safety installations depend on reliable communication, especially during fires, evacuations, or natural disasters. Rainproof weatherproof telephones form a core part of these systems. They operate alongside heat detectors, horn strobes, and fire alarm call points to guarantee dependable communication in harsh environments.

- These telephones ensure clear, continuous communication during emergencies, even outdoors or in wet conditions.

- They support coordination, alerting, and evacuation by maintaining open lines regardless of weather.

- Integration with voice evacuation and emergency PA systems enhances overall safety.

Modern models use durable materials and waterproof keypads. They support analog, VoIP, SIP, GSM, and 3G protocols, allowing seamless integration with broader emergency networks. Features like alarm sound horns and call progress indicators further improve their effectiveness in critical situations.

Callout: When installing these telephones in remote or hazardous locations, planners must address challenges such as power supply, surge protection, and environmental compliance. Using IP65 or higher rated enclosures and Power over Ethernet (PoE) solutions helps maintain reliable operation.

A rainproof weatherproof telephone protects communication in harsh environments. Its rugged design, proven by use in tunnels and marine sites, prevents failures from water, dust, and impacts. Organizations see fewer repairs and safer operations. Any site facing severe weather or hazards should consider these phones for reliable, long-term performance.

FAQ

What is the difference between rainproof and weatherproof telephones?

Rainproof telephones protect against rain only. Weatherproof telephones resist rain, dust, and extreme temperatures. Weatherproof models offer broader protection for harsh environments.

How long do rainproof weatherproof telephones last?

Most models last over 10 years with proper maintenance. Rugged materials and sealed enclosures help extend the device’s lifespan in tough conditions.

Tip: Regular inspections and cleaning keep telephones working longer and reduce repair costs.

Can these telephones work with modern communication systems?

Yes. Many rainproof weatherproof telephones support analog, VoIP, SIP, and GSM networks. They integrate easily with existing communication and emergency systems.