A Silicon Carbide Robotic Arm uses silicon carbide, a tough and heat-resistant material. This arm has motor-driven joints that move with accuracy. Engineers choose this design for work in places with high heat or heavy wear. The strong material helps the arm last longer and perform better.

Key Takeaways

- Silicon carbide makes robotic arms very strong, heat-resistant, and durable, allowing them to work well in tough environments like factories and chemical plants.

- These robotic arms move with high precision and need less maintenance, which helps factories save time and money while reducing errors.

- Silicon carbide robotic arms are ideal for industries that require machines to handle heat, chemicals, or heavy loads without wearing out quickly.

Why Choose a Silicon Carbide Robotic Arm

Key Properties of Silicon Carbide

Silicon carbide stands out as a material with unique qualities. It has extreme hardness, which means it resists scratches and dents. This material also handles very high temperatures without breaking down. Engineers value its ability to stay strong even when exposed to chemicals or heavy use.

Tip: Silicon carbide does not rust or corrode easily. This makes it a smart choice for machines that work in tough places.

A table below shows some important properties:

| Property | Description |

|---|---|

| Hardness | Очень высоко |

| Heat Resistance | Withstands extreme heat |

| Chemical Stability | Resists corrosion |

| Durability | Lasts a long time |

Advantages Over Traditional Materials

Many robotic arms use steel or aluminum. These metals can bend, rust, or wear out over time. A Silicon Carbide Robotic Arm offers better performance in harsh environments. It keeps its shape and strength, even after years of use.

- It works well in factories with high heat.

- It does not need as much maintenance.

- It can handle heavy loads without bending.

Engineers choose this type of arm when they need reliability and long life. The special properties of silicon carbide help the robotic arm do jobs that other materials cannot handle.

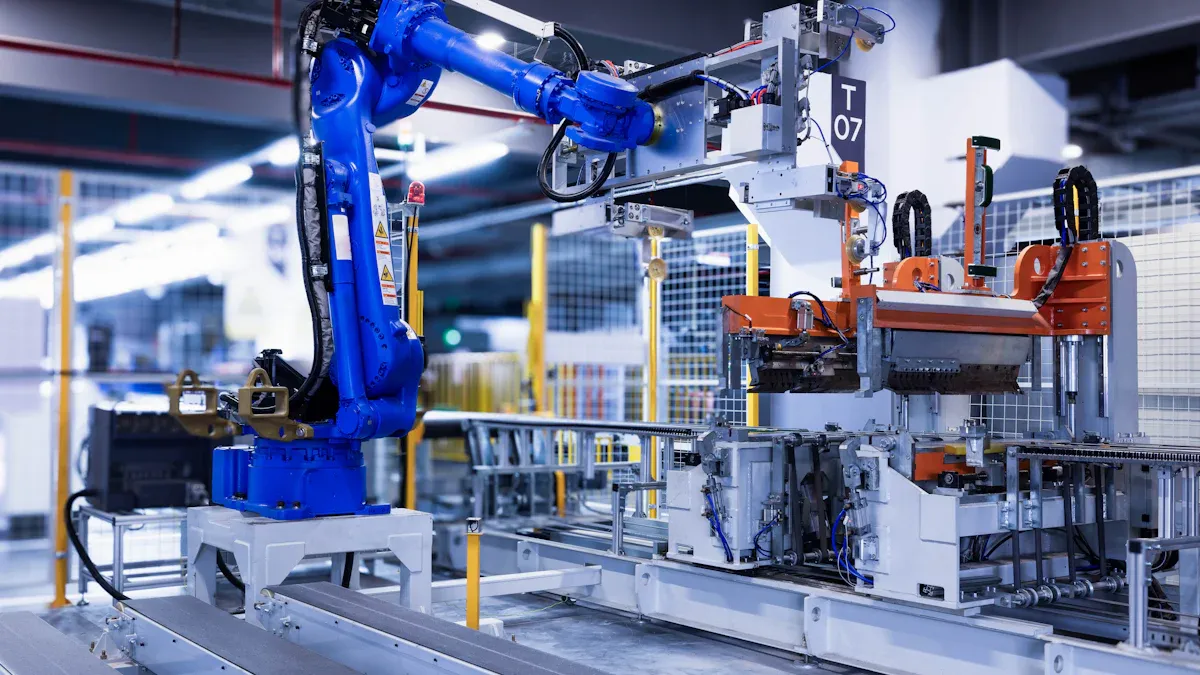

How a Silicon Carbide Robotic Arm Works

Main Components and Mechanisms

A Silicon Carbide Robotic Arm uses several important parts to move and work. Each part has a special job. The main components include:

- Joints and Actuators: These parts help the arm bend, rotate, and reach. Motors inside the joints make the arm move smoothly and with control.

- Links: These are the solid sections between the joints. Engineers often use silicon carbide for these links because it is strong and does not bend easily.

- End Effector: This is the tool at the end of the arm. It can grab, weld, or cut, depending on the job.

- Sensors: These devices help the arm know its position and how much force it uses. Sensors also help the arm avoid mistakes.

- Control System: This system acts like the brain. It sends signals to the motors and sensors. The control system makes sure the arm moves the right way.

Note: The use of silicon carbide in the links and joints gives the arm extra strength and heat resistance. This helps the arm work in places where other materials might fail.

The arm moves by following commands from the control system. The motors turn the joints, and the sensors give feedback. This process allows the arm to perform tasks with high accuracy.

Typical Applications

A Silicon Carbide Robotic Arm works well in many industries. Its special material lets it handle tough jobs. Some common uses include:

- Производство: Factories use these arms to move heavy parts, weld metal, or assemble products. The arm can work in hot areas near furnaces or ovens.

- Aerospace: Workers use the arm to build airplane parts or test engines. The arm’s strength and heat resistance help it last longer in these settings.

- Химическая обработка: The arm can handle dangerous chemicals without corroding. This makes it safe for mixing or moving chemical materials.

- Semiconductor Industry: The arm can work in clean rooms to build computer chips. Its smooth surface and strength help prevent contamination.

- Automotive: Car makers use the arm for painting, welding, and assembling cars. The arm’s durability means it can work for many years without breaking down.

Tip: Many companies choose a Silicon Carbide Robotic Arm when they need a machine that can work in extreme heat, handle heavy loads, or resist chemicals.

These applications show how the arm’s design and material help it solve problems that other robotic arms cannot.

Benefits of Silicon Carbide Robotic Arm Technology

Precision and Stability

A Silicon Carbide Robotic Arm moves with great accuracy. The strong material keeps the arm steady during fast or heavy tasks. Engineers trust this arm for jobs that need careful placement, such as assembling small parts or handling delicate items. The sensors and control system work together to guide each movement. This teamwork helps the arm avoid mistakes and keeps the process smooth.

Note: High precision means fewer errors and less waste in factories.

Durability and Longevity

Silicon carbide gives the robotic arm a long life. The arm does not wear out quickly, even after many hours of work. Factories can use the same arm for years without replacing it. This saves money and time. The hard surface resists scratches and dents, so the arm keeps working well. Many companies choose this arm because it stays strong and reliable.

| Feature | Benefit |

|---|---|

| Hard surface | Less damage |

| Long lifespan | Меньше замены |

| Reliable build | Consistent results |

Resistance to Harsh Environments

The Silicon Carbide Robotic Arm works in places where heat, chemicals, or dust might damage other machines. It keeps its shape and strength in extreme conditions. Workers use this arm in hot factories, chemical plants, and clean rooms. The arm does not rust or corrode, so it stays safe and clean.

- Handles high temperatures

- Resists chemical damage

- Works well in dusty or wet areas

Tip: This arm is a smart choice for tough jobs that need a strong and stable machine.

A Silicon Carbide Robotic Arm gives factories strong, reliable tools for tough jobs. This technology stands out in places where heat or chemicals cause problems. Many industries now choose these arms for better performance. As automation grows, these arms will help shape the future of manufacturing.

FAQ

What makes silicon carbide better than steel for robotic arms?

Silicon carbide stays strong in high heat and does not rust. Steel can bend or corrode. Factories use silicon carbide for tough jobs.

Note: Silicon carbide lasts longer in harsh places.

Can a silicon carbide robotic arm work in clean rooms?

Yes. The smooth surface of silicon carbide helps keep dust away. Workers use these arms to build computer chips and other clean products.

How long does a silicon carbide robotic arm last?

Most silicon carbide robotic arms work for many years. The hard material resists damage. Companies save money because they replace the arms less often.