When processing 300mm wafers, you need materials that can withstand extreme conditions. CVD Покрытие SiC offers unmatched durability, thermal stability, and resistance to chemicals. These properties ensure reliable performance and reduce contamination risks. With this coating, you achieve precision and efficiency, making it indispensable for advanced semiconductor manufacturing.

Key Takeaways

- CVD Покрытие SiC is very strong and protects tools. This lowers the need to replace them often.

- Покрытие handles high heat well, keeping it stable. It stops bending during wafer processing.

- CVD SiC Coating keeps things clean, improving wafer quality. This helps make more wafers successfully.

Unique Advantages of CVD SiC Coating

Durability and Hardness

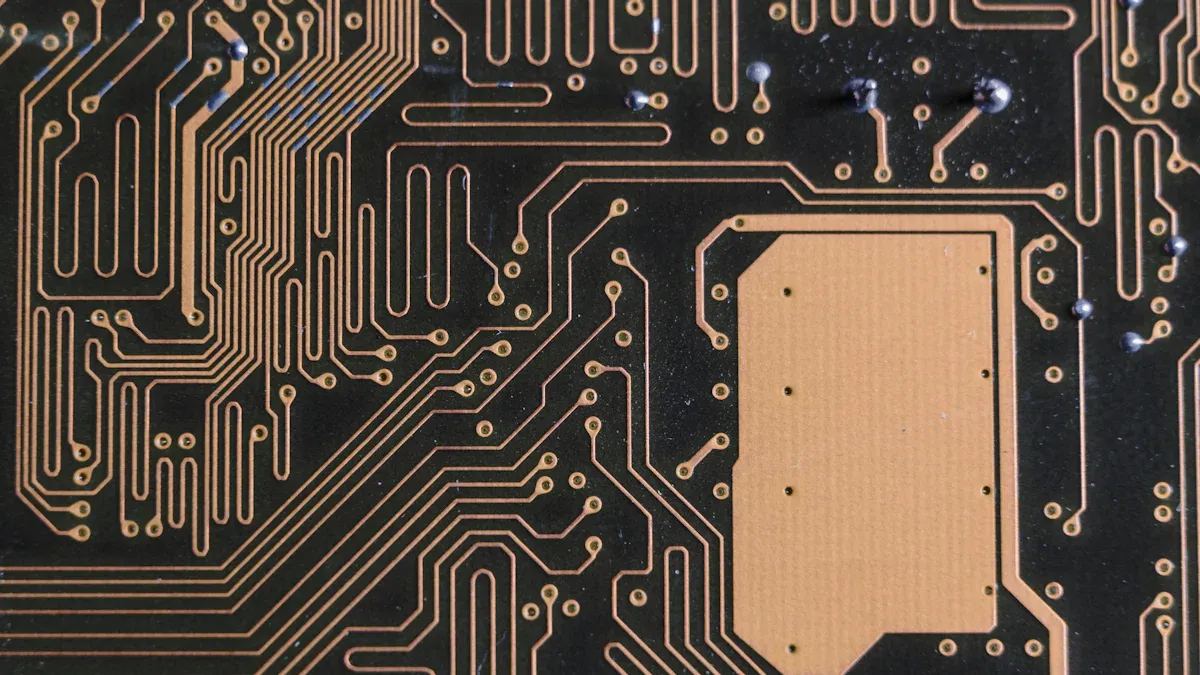

When working with 300mm wafers, you need materials that can handle constant stress without breaking down. CVD SiC Coating offers exceptional durability due to its high hardness. This coating resists wear and tear, even in the most demanding environments. Its hardness ensures that tools and components maintain their structural integrity over time.

You can rely on this coating to protect your equipment from scratches, cracks, and other forms of damage. This durability reduces the need for frequent replacements, saving both time and resources. In semiconductor manufacturing, where precision is critical, this level of reliability is invaluable.

Thermal Stability

High temperatures are a common challenge in wafer processing. CVD SiC Coating excels in thermal stability, making it ideal for such conditions. It can withstand extreme heat without losing its properties or degrading. This stability ensures consistent performance, even during prolonged exposure to high temperatures.

You benefit from this feature because it minimizes the risk of thermal expansion or warping. This means your equipment remains accurate and efficient, even under intense heat. By maintaining its structure and performance, the coating supports the production of high-quality wafers.

Chemical and Oxidation Resistance

Chemical exposure is another challenge in semiconductor manufacturing. CVD SiC Coating provides excellent resistance to chemicals and oxidation. It acts as a barrier, protecting your equipment from corrosive substances used during wafer processing.

This resistance ensures that the coating remains intact, even when exposed to harsh chemicals. You can trust it to prevent contamination and maintain a clean processing environment. Additionally, its oxidation resistance helps extend the lifespan of your equipment, reducing maintenance costs and downtime.

Tip: Choosing materials with strong chemical and oxidation resistance can significantly improve the efficiency of your manufacturing process.

Addressing Challenges in 300mm Wafer Processing

Предотвращение загрязнения

Contamination is one of the biggest obstacles in semiconductor manufacturing. Even the smallest particles can compromise the quality of your wafers. CVD Покрытие SiC helps you tackle this issue effectively. Its chemical resistance creates a protective barrier that prevents contaminants from adhering to surfaces during processing.

You can rely on this coating to maintain a clean environment. It minimizes the risk of impurities transferring to your wafers, ensuring consistent quality. By reducing contamination, you also improve the reliability of your equipment and avoid costly production delays.

Note: A clean processing environment is critical for achieving high yields in semiconductor manufacturing.

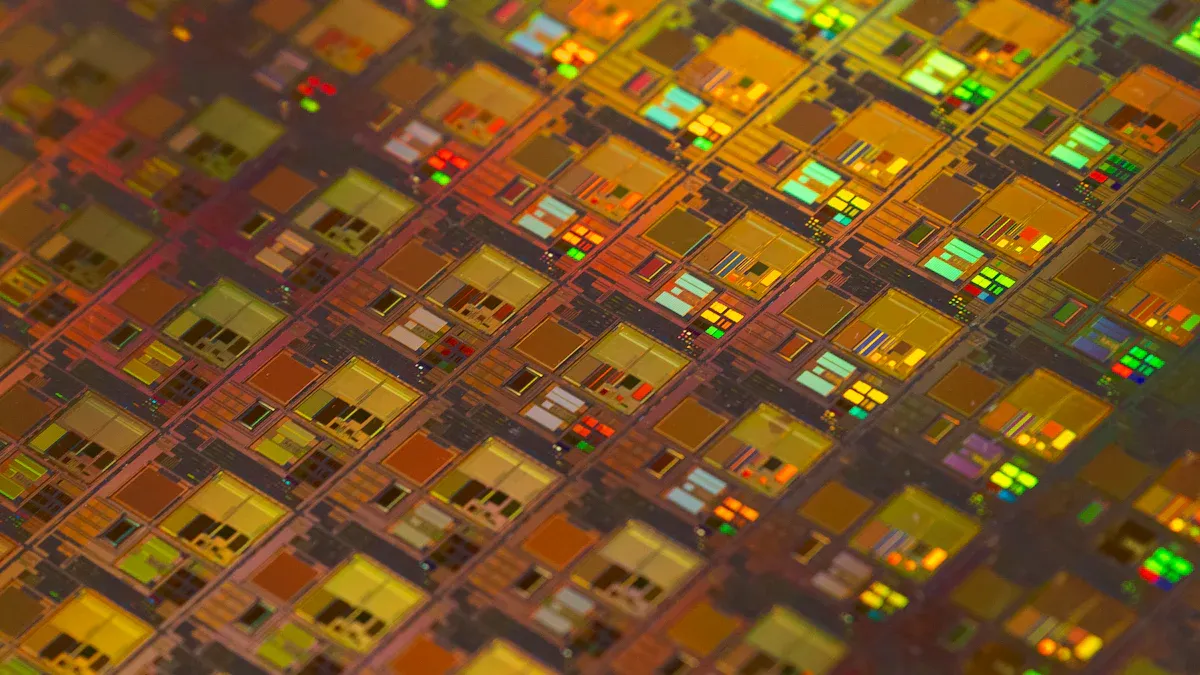

Uniformity Across Larger Wafer Surfaces

Achieving uniformity across 300mm wafers is challenging due to their size. Variations in thickness or surface properties can lead to defects and lower yields. CVD SiC Coating ensures uniformity by providing a consistent layer across larger surfaces.

This uniformity allows you to produce wafers with precise specifications. It reduces the likelihood of defects and enhances the performance of your final products. With this coating, you can meet the stringent requirements of advanced semiconductor applications.

- Key Benefits of Uniformity:

- Improved wafer quality

- Reduced defect rates

- Enhanced device performance

Longevity of Equipment

Equipment longevity is essential for cost-effective manufacturing. Frequent replacements or repairs can disrupt your operations and increase expenses. CVD SiC Coating extends the lifespan of your equipment by protecting it from wear, corrosion, and thermal damage.

You benefit from reduced maintenance needs and longer intervals between replacements. This durability ensures that your tools and components remain functional over extended periods. By investing in this coating, you save time and resources while maintaining high production efficiency.

Tip: Longer equipment life translates to lower operational costs and higher profitability.

Benefits for Semiconductor Companies

Cost-Effectiveness

CVD SiC Coating offers significant cost savings for semiconductor companies. Its durability reduces the frequency of equipment replacements. You spend less on repairs and maintenance, which lowers operational costs. The coating also minimizes downtime by keeping your tools in excellent condition. This ensures uninterrupted production, saving you both time and money.

Additionally, the coating’s resistance to wear and corrosion extends the lifespan of your equipment. You can allocate resources to other critical areas of your operations instead of constantly replacing damaged components. Over time, these savings add up, making CVD SiC Coating a smart investment for your manufacturing processes.

Improved Yield

Achieving high yields is essential in semiconductor manufacturing. CVD SiC Coating helps you produce wafers with fewer defects. Its uniform application ensures consistent quality across all 300mm wafers. This consistency reduces the likelihood of errors during production.

By preventing contamination and maintaining a clean processing environment, the coating further enhances yield rates. You can meet stringent industry standards while maximizing output. Higher yields mean more reliable products and greater profitability for your business.

Long-Term Reliability

Reliability is crucial in advanced manufacturing. CVD SiC Coating ensures your equipment performs consistently over time. Its resistance to extreme temperatures and chemicals protects your tools from damage. You can trust this coating to maintain its properties even under challenging conditions.

This long-term reliability translates to fewer disruptions in your production line. You can focus on innovation and scaling your operations without worrying about equipment failures. With CVD SiC Coating, you build a foundation for sustainable growth and operational excellence.

CVD SiC Coating offers unmatched durability, thermal stability, and chemical resistance. It prevents contamination and ensures uniformity across 300mm wafers, solving critical manufacturing challenges. You gain cost savings, higher yields, and reliable equipment performance. This coating empowers you to achieve precision and efficiency, making it the ideal choice for advanced semiconductor manufacturing.

FAQ

What makes CVD SiC Coating better than other materials for wafer processing?

CVD Покрытие SiC offers superior durability, thermal stability, and chemical resistance. These properties ensure reliable performance, reduce contamination risks, and extend equipment lifespan.

Can CVD SiC Coating handle extreme manufacturing conditions?

Yes, it withstands high temperatures, corrosive chemicals, and mechanical stress. Its robust properties make it ideal for demanding semiconductor manufacturing environments.

How does CVD SiC Coating improve wafer quality?

It ensures uniformity across 300mm wafers, prevents contamination, and reduces defects. These features enhance wafer quality and improve overall production yield.

Tip: Regularly inspect coated equipment to maintain optimal performance and extend its lifespan.