You often need parts that can handle tough jobs. A Graphite Bearing/Bushing works well in places with high heat or strong chemicals. You do not have to add oil because it can lubricate itself. This means you spend less time fixing machines and more time getting work done.

Key Takeaways

- Graphite bearings and bushings resist high heat and chemicals, making them ideal for tough industrial environments.

- These parts lubricate themselves, reducing the need for oil and lowering maintenance time and costs.

- Using graphite bearings improves machine reliability, safety, and product quality across many industries.

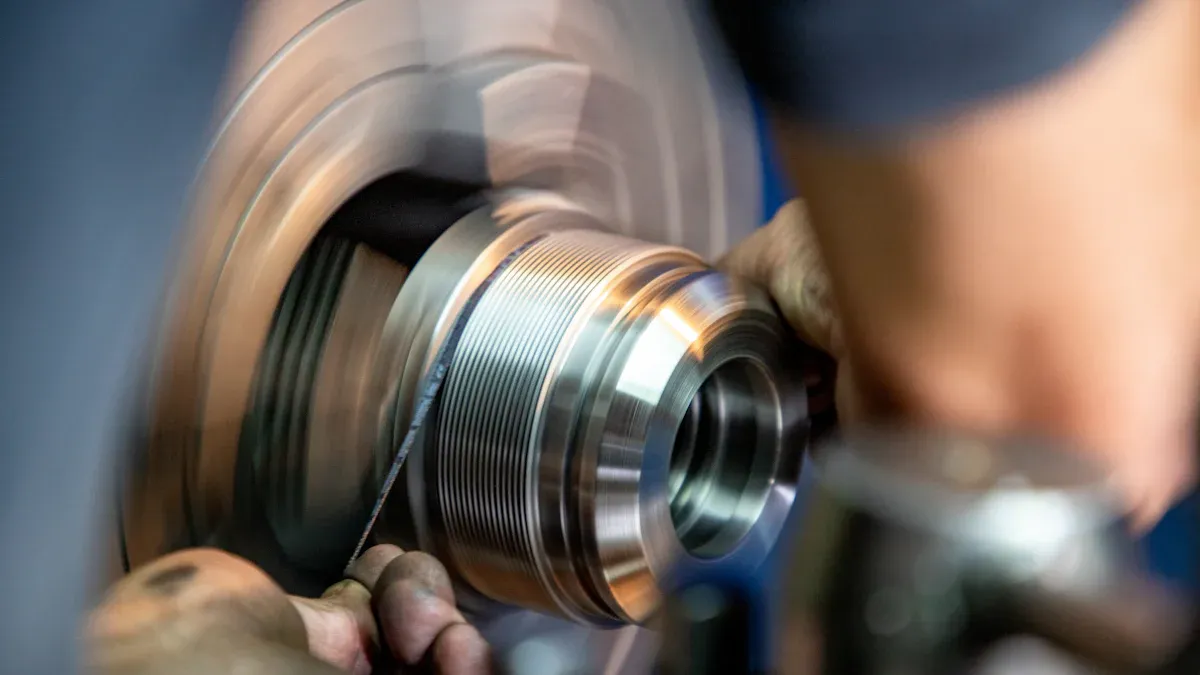

Steel and Metal Processing with Graphite Bearing/Bushing

Steel and metal processing plants face extreme conditions. You often deal with high temperatures, heavy loads, and harsh chemicals. Ordinary bearings can fail quickly in these environments. You need parts that last longer and require less maintenance. Graphite Bearing/Bushing solutions help you keep your machines running smoothly.

Continuous Casting Machine Graphite Bearing/Bushing

Continuous casting machines shape molten metal into solid forms. These machines run non-stop and reach very high temperatures. You need bearings that can handle heat and keep working without extra oil. Graphite Bearing/Bushing parts work well here because they can self-lubricate. They do not melt or break down when exposed to hot metal.

Tip: Using graphite bearings in continuous casting machines helps you avoid frequent shutdowns for maintenance.

You also get better product quality. The smooth movement of the machine means fewer defects in the metal. You save time and money because you do not need to stop production to replace worn-out parts.

Furnace Conveyor Graphite Bearing/Bushing

Furnace conveyors move heavy metal parts through ovens and furnaces. These conveyors face intense heat and sometimes corrosive gases. Regular bearings can seize up or wear out fast. You need a solution that stands up to these tough conditions.

Graphite bearings work well in furnace conveyors. They resist heat and do not need extra lubrication. You can trust them to keep moving even when other materials fail. This means your conveyor runs longer and needs less attention from you.

Here is a quick comparison:

| Feature | Regular Bearings | Graphite Bearings |

|---|---|---|

| Handles High Heat | ❌ | ✅ |

| Needs Lubrication | ✅ | ❌ |

| Resists Corrosion | ❌ | ✅ |

| Частота обслуживания | High | Low |

You get more uptime and fewer repairs. Your production line stays efficient, and you avoid costly delays.

Chemical Processing Industry Graphite Bearing/Bushing

Pump and Agitator Graphite Bearing/Bushing

You often work with pumps and agitators in chemical plants. These machines move liquids and mix chemicals. Many chemicals can damage regular bearings. High temperatures and strong acids make the job even harder. When you use a Graphite Bearing/Bushing, you get a part that resists both heat and corrosion. This means your equipment lasts longer and needs less repair.

Note: Graphite bearings do not need oil or grease. This helps you avoid contamination in sensitive chemical processes.

You also save time because you do not have to stop machines for frequent maintenance. Pumps and agitators run smoother, and you get better results from your process.

Valve Component Graphite Bearing/Bushing

Valves control the flow of liquids and gases in your plant. These parts must open and close many times each day. Chemicals and high pressure can wear out normal bushings quickly. You need a solution that stands up to these tough conditions.

Graphite bushings work well in valve components. They handle harsh chemicals and keep working even when temperatures rise. You get reliable performance and fewer leaks. Your plant stays safe, and you avoid costly shutdowns.

Here is a quick list of benefits:

- No extra lubrication needed

- High resistance to chemicals

- Долгой срок службы

Food and Beverage Manufacturing Graphite Bearing/Bushing

Oven and Baking Equipment Graphite Bearing/Bushing

You need equipment that can handle high heat and constant use in bakeries and food plants. Ovens and baking machines run for long hours. The parts inside face both heat and food particles. Regular bearings can break down or need oil, which can mix with food. You want to avoid this risk.

Graphite Bearing/Bushing parts work well in these ovens. They do not need extra oil or grease. This means you keep your food safe from contamination. You also get less downtime because these parts last longer. Your ovens stay clean and run smoothly.

Tip: Choose graphite bushings for baking equipment to meet food safety standards and reduce cleaning time.

Conveyor System Graphite Bearing/Bushing

Conveyor systems move food items from one step to another. These systems must stay clean and work without stopping. If a bearing fails, your whole line can stop. You want a solution that keeps things moving.

Graphite bushings help your conveyors run with less maintenance. They resist wear from both heat and cleaning chemicals. You do not need to add oil, so you avoid mess and keep your food safe. Your production line stays fast and reliable.

Here is a quick look at the benefits:

- No risk of oil leaks

- Легко чистить

- Долгой срок службы

- Safe for food contact

Aerospace and Defense Graphite Bearing/Bushing

High-Temperature Actuator Graphite Bearing/Bushing

You need reliable parts in aerospace and defense systems. High-temperature actuators help control moving parts in engines, wings, and landing gear. These actuators often face extreme heat and heavy loads. Regular bearings can fail when exposed to these tough conditions. You want a solution that keeps working even when temperatures rise.

Graphite Bearing/Bushing parts handle high heat without melting or losing strength. They keep actuators moving smoothly. You do not need to add oil, so you avoid sticky buildup or dirt. This helps your equipment last longer and work better.

Tip: Using graphite bushings in actuators can reduce the risk of sudden failure during flight.

Fuel System Component Graphite Bearing/Bushing

Fuel systems in aircraft and defense vehicles must stay safe and reliable. You need parts that resist both chemicals and temperature changes. Regular bushings can wear out quickly when exposed to jet fuel or other harsh liquids.

Graphite bushings work well in fuel pumps, valves, and other system parts. They do not react with fuel or corrode. You get steady performance and fewer leaks. Your fuel system stays clean and safe, which is very important for flight safety.

Here is a quick list of benefits:

- Handles extreme temperatures

- Resists chemical attack

- Needs little maintenance

Power Generation Graphite Bearing/Bushing

Turbine Support System Graphite Bearing/Bushing

You need strong and reliable parts in power plants. Turbines spin at high speeds and face heavy loads. Heat and friction can wear out regular bearings fast. When you use a Graphite Bearing/Bushing, you get a part that handles high temperatures and keeps moving smoothly. This helps your turbine run longer and with less noise.

Tip: Graphite bushings do not need oil, so you avoid messy leaks and lower your maintenance time.

You also get better safety. Turbines work in tough places, and you want every part to last. Graphite bushings resist damage from heat and pressure. This means fewer shutdowns and more power for your plant.

Boiler Feed Pump Graphite Bearing/Bushing

Boiler feed pumps move water into boilers. These pumps work under high pressure and heat. Regular bushings can break down or need lots of repairs. You want a solution that stands up to these hard jobs.

Graphite bushings help your pumps run without extra oil. They resist both heat and chemicals in the water. You spend less time fixing pumps and more time making power. Your plant stays safe and efficient.

Here is a quick table to show the benefits:

| Feature | Regular Bushing | Graphite Bushing |

|---|---|---|

| Needs Lubrication | Yes | No |

| Handles High Heat | No | Yes |

| Resists Chemicals | No | Yes |

| Maintenance Needed | High | Low |

Glass and Ceramics Production Graphite Bearing/Bushing

Kiln Car Graphite Bearing/Bushing

You use kiln cars to move heavy loads of ceramics or glass through hot kilns. These cars face extreme heat every day. Regular bearings can melt or wear out fast in these conditions. You need a solution that stands up to high temperatures and keeps your kiln car moving.

Graphite Bearing/Bushing parts work well in kiln cars. They do not need oil, so you avoid messy leaks. They also resist damage from heat and dust. You get longer service life and fewer breakdowns. This means your production line stays on schedule.

Tip: Choose graphite bushings for kiln cars to reduce maintenance and avoid costly downtime.

Glass Forming Equipment Graphite Bearing/Bushing

Glass forming equipment shapes hot glass into bottles, jars, and other products. The machines run at high temperatures and must move smoothly. If a bearing fails, you can lose product and slow down your process.

You can trust graphite bushings in glass forming machines. They handle heat and do not react with glass or chemicals. You get smooth movement and less wear on your equipment. Cleaning becomes easier because you do not have sticky oil or grease.

Here are some benefits:

- Handles high heat

- Needs no extra lubrication

- Lasts longer than regular bearings

Automotive Industry Graphite Bearing/Bushing

Exhaust System Graphite Bearing/Bushing

You need parts in your car’s exhaust system that can handle heat and harsh gases. The exhaust system faces high temperatures every time you drive. Regular bushings can wear out quickly in these conditions. When you use a Graphite Bearing/Bushing, you get a part that stands up to heat and does not break down from exhaust fumes.

Graphite bushings help your exhaust system move smoothly. They do not need oil, so you avoid leaks and mess. You also get less noise and vibration. This means your car runs quieter and parts last longer.

Tip: Choose graphite bushings for exhaust systems to reduce maintenance and improve reliability.

Electric Motor Graphite Bearing/Bushing

Electric motors power many parts of your car, like fans, pumps, and even the main drive in electric vehicles. These motors spin fast and need reliable support. Regular bearings can fail if they get too hot or if dust gets inside.

Graphite bushings work well in electric motors. They resist heat and do not need extra oil. You get smooth, quiet operation. Your motor lasts longer and needs less repair.

Here is a quick comparison:

| Feature | Regular Bearing | Graphite Bearing/Bushing |

|---|---|---|

| Needs Lubrication | Yes | No |

| Handles High Heat | No | Yes |

| Quiet Operation | Sometimes | Yes |

You keep your car running better and spend less time on repairs.

Water and Wastewater Treatment Graphite Bearing/Bushing

Submersible Pump Graphite Bearing/Bushing

You often rely on submersible pumps to move water in treatment plants. These pumps work underwater and face harsh conditions. Water can carry sand, chemicals, and other particles that damage regular bearings. When you use a Graphite Bearing/Bushing, you get a part that resists both corrosion and wear. This helps your pump last longer and run smoothly.

Graphite bushings do not need oil or grease. You avoid messy leaks and keep your water clean. These bushings also handle changes in temperature and pressure. Your pump keeps working, even when conditions change quickly.

Tip: Choose graphite bushings for submersible pumps to reduce maintenance and avoid unexpected breakdowns.

Chemical Dosing Equipment Graphite Bearing/Bushing

Chemical dosing equipment adds precise amounts of chemicals to water. You need reliable parts because even small failures can cause big problems. Many chemicals used in treatment plants can damage metal or plastic bushings. Graphite bushings resist strong acids and bases. You get steady performance and fewer repairs.

Here are some benefits of using graphite bushings in dosing equipment:

- No extra lubrication needed

- High resistance to chemicals

- Долгой срок службы

You keep your water treatment process safe and efficient. Your equipment stays reliable, and you spend less time on repairs.

Textile Manufacturing Graphite Bearing/Bushing

Drying and Heat Setting Machine Graphite Bearing/Bushing

You use drying and heat setting machines to finish fabrics. These machines run at high temperatures for long hours. Regular bearings can wear out quickly in this environment. When you choose a Graphite Bearing/Bushing, you get a part that handles heat and keeps your machine running smoothly. You do not need to add oil, so you avoid stains on your fabric.

Tip: Graphite bushings help you reduce downtime and keep your production line moving.

You also get less noise and smoother movement. This means your fabric comes out even and free from marks. You spend less time on repairs and more time making quality textiles.

Dyeing Equipment Graphite Bearing/Bushing

Dyeing equipment works with hot water and strong chemicals. These conditions can damage regular bushings. You want a solution that resists both heat and chemicals. Graphite bushings give you this protection. They do not react with dyes or cleaning agents.

Here are some reasons to use graphite bushings in dyeing equipment:

- No extra lubrication needed

- High resistance to chemicals

- Долгой срок службы

You keep your dyeing machines clean and safe. Your colors stay bright, and your equipment lasts longer.

Pharmaceutical Industry Graphite Bearing/Bushing

Sterilization Equipment Graphite Bearing/Bushing

You need reliable equipment to keep your pharmaceutical products safe. Sterilization machines use high heat and steam to kill germs. Many parts inside these machines face extreme temperatures and moisture. Regular bushings can wear out quickly or even rust. You want a solution that stands up to these tough conditions.

Graphite Bearing/Bushing parts work well in sterilization equipment. They do not need oil, so you avoid the risk of contamination. These bushings resist both heat and chemicals. You get longer service life and fewer breakdowns. Your machines stay clean and safe for every batch.

Tip: Using graphite bushings in sterilizers helps you meet strict hygiene standards and reduces maintenance time.

Mixing and Blending Machine Graphite Bearing/Bushing

Mixing and blending machines help you combine powders and liquids to make medicines. These machines run for long hours and must stay clean. Regular bearings can leak oil or break down from strong cleaning agents. You want a part that keeps your process smooth and safe.

Graphite bushings give you steady performance in mixing and blending machines. They do not need extra lubrication, so you avoid oil leaks. These bushings also resist harsh chemicals used for cleaning. You spend less time on repairs and more time making quality products.

Here are some benefits:

- No oil contamination

- High resistance to cleaning chemicals

- Long-lasting and reliable

You can trust Graphite Bearing/Bushing solutions in tough jobs. These parts work well in heat, chemicals, and heavy use. You save time on repairs and keep your machines running. For special needs, talk to experts. They help you pick the best part for your work.

Remember: The right choice gives you longer-lasting equipment.

FAQ

What makes graphite bearings better than metal bearings?

You get self-lubrication, high heat resistance, and chemical stability. Graphite bearings last longer in tough environments. You also avoid oil leaks and reduce maintenance.

Can you use graphite bushings in food processing equipment?

Yes, you can. Graphite bushings do not need oil. You keep your food safe from contamination and meet strict hygiene standards.

How often should you replace graphite bearings?

You replace them less often than regular bearings. Graphite bearings resist wear and heat. You save time and money on maintenance.