Epitaxy has revolutionized material engineering by enabling precise control over atomic structures. To understand the epitaxy meaning, it refers to the process of growing one crystal layer on top of another, creating materials with superior properties. This method is essential in advancing technologies like epitaxy semiconductor applications, photonics, and quantum computing. Through epitaxial growth semiconductor devices are becoming smaller, faster, and more efficient. Exploring the epitaxy definition and its techniques is crucial for unlocking future innovations. As you delve into epitaxy, you’ll uncover its potential to shape groundbreaking applications.

Key Takeaways

- Epitaxy helps make advanced materials with exact atomic designs. It is important for semiconductors and quantum computers.

- Molecular Beam Epitaxy (MBE) is very accurate but slow and expensive. Metal-Organic Chemical Vapor Deposition (MOCVD) is faster and better for factories.

- Hybrid methods mix different techniques to improve materials and make production easier. These are great for tricky applications.

- Epitaxy in 2D materials creates chances for bendable electronics and energy storage. These materials have special features.

- AI is changing epitaxy by improving processes and fixing mistakes. This helps new materials get made faster.

Epitaxy Meaning and Current Techniques

Epitaxy plays a vital role in material engineering by enabling the growth of high-quality crystal layers. Understanding the epitaxy meaning helps you appreciate how this process creates materials with exceptional properties. Several techniques have been developed to achieve precise control over crystal growth. Each method offers unique advantages for specific applications.

Molecular Beam Epitaxy (MBE)

Molecular Beam Epitaxy (MBE) is one of the most precise techniques for growing thin films. In this method, you use a vacuum chamber to create an ultra-clean environment. Inside, beams of atoms or molecules are directed onto a heated substrate. These particles condense and form a crystalline layer.

MBE allows you to control the growth process at the atomic level. This precision makes it ideal for research and development in semiconductors and quantum materials. However, the process is slow and expensive, which limits its use in large-scale production.

Tip: MBE is often used in laboratories to create materials for cutting-edge technologies like quantum computing.

Metal-Organic Chemical Vapor Deposition (MOCVD)

Metal-Organic Chemical Vapor Deposition (MOCVD) is a widely used technique for producing thin films. In this process, you introduce metal-organic compounds and other gases into a reaction chamber. These gases decompose on a heated substrate, forming a crystalline layer.

MOCVD is faster and more scalable than MBE. It is commonly used in the production of LEDs, solar cells, and other semiconductor devices. While it offers high efficiency, controlling defects during the process can be challenging.

Note: MOCVD is a key method for manufacturing devices that power renewable energy technologies.

Atomic Layer Epitaxy (ALE)

Atomic Layer Epitaxy (ALE) is a technique that focuses on growing materials one atomic layer at a time. You alternate between different chemical precursors, which react with the substrate surface. This step-by-step approach ensures uniformity and precision.

ALE is ideal for creating ultra-thin films with excellent quality. It is often used in applications requiring nanoscale precision, such as advanced transistors and memory devices. Although ALE offers unmatched control, it is slower compared to other methods.

Did you know? ALE is a critical technique for developing next-generation semiconductors.

Each of these techniques contributes to the advancement of epitaxy. By understanding their strengths and limitations, you can choose the best method for your specific needs.

Innovations in Epitaxial Growth

Hybrid Growth Methods

Hybrid growth methods combine the strengths of different epitaxial techniques to create materials with superior properties. For example, you might use Molecular Beam Epitaxy (MBE) for its precision and pair it with Metal-Organic Chemical Vapor Deposition (MOCVD) for scalability. This approach allows you to achieve both high-quality crystal layers and faster production rates.

These methods are especially useful when working with complex materials like heterostructures, where multiple layers with different compositions are required. By blending techniques, you can overcome limitations such as defect formation or slow growth rates. Hybrid methods open new possibilities for creating advanced semiconductors and optoelectronic devices.

Tip: Experimenting with hybrid methods can help you tailor materials for specific applications, such as high-performance lasers or sensors.

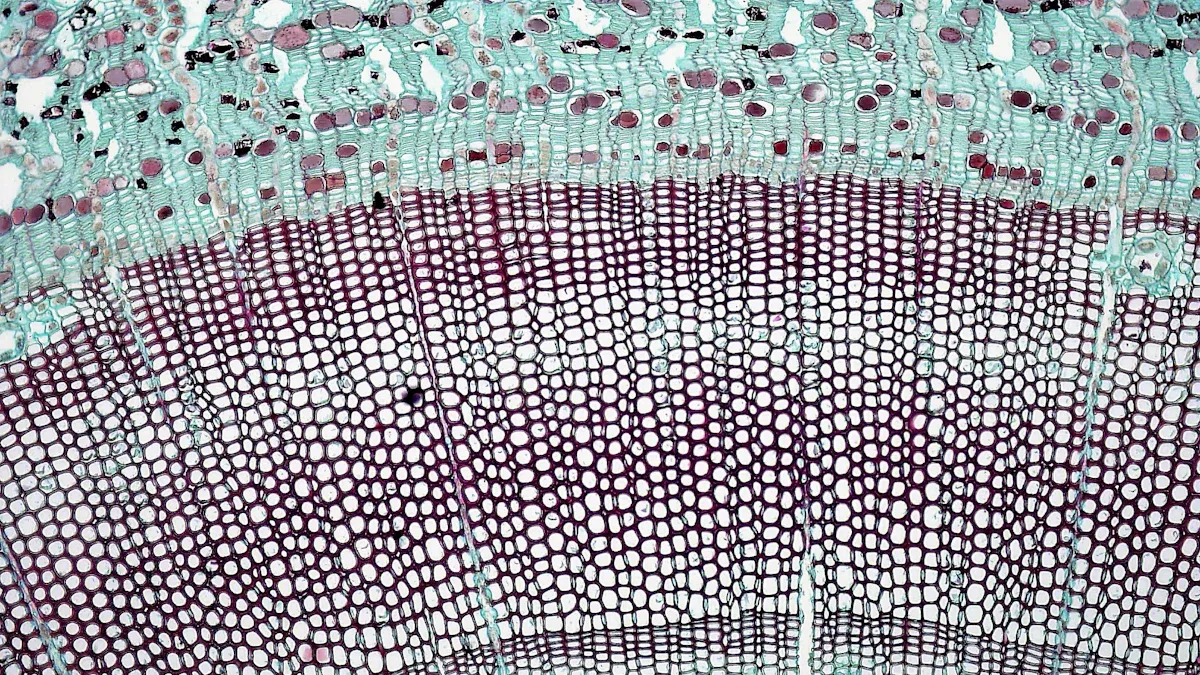

Advances in 2D Materials

Two-dimensional (2D) materials, like graphene and transition metal dichalcogenides (TMDs), have transformed the field of epitaxy. These materials consist of a single layer of atoms, giving them unique electrical, optical, and mechanical properties. Through epitaxial growth, you can produce high-quality 2D materials with precise control over their structure and thickness.

You might find 2D materials particularly exciting for applications in flexible electronics, energy storage, and quantum computing. Their atomically thin nature makes them ideal for miniaturized devices. Advances in epitaxy techniques now allow you to stack multiple 2D layers, creating van der Waals heterostructures with tailored properties.

Did you know? Epitaxy plays a crucial role in unlocking the potential of 2D materials for next-generation technologies.

AI-Optimized Epitaxy

Artificial intelligence (AI) is revolutionizing how you approach epitaxial growth. By analyzing vast datasets, AI can predict optimal growth conditions, reducing trial-and-error experiments. Machine learning algorithms help you identify the best parameters for temperature, pressure, and material composition.

AI also enables real-time monitoring and adjustment during the growth process. This ensures consistent quality and minimizes defects. With AI, you can accelerate the development of new materials and improve the efficiency of existing techniques. The integration of AI into epitaxy is paving the way for breakthroughs in semiconductors, photonics, and beyond.

Note: AI-optimized epitaxy is a game-changer for industries aiming to innovate faster and more efficiently.

Challenges in Epitaxial Growth

Defect Control

Defects in epitaxial layers can significantly impact the performance of materials. You might encounter issues like dislocations, impurities, or uneven growth. These defects often arise from mismatches between the substrate and the material being grown. For example, if the lattice structures of the two materials don’t align perfectly, it can lead to strain and defects.

To minimize defects, you need to carefully control growth conditions such as temperature, pressure, and deposition rates. Advanced monitoring tools, like in-situ spectroscopy, can help you detect and address issues during the growth process. However, achieving defect-free layers remains a complex challenge, especially for large-scale production.

Tip: Start with high-quality substrates to reduce the likelihood of defects in your epitaxial layers.

Scalability and Cost

Scaling epitaxial growth techniques for industrial use can be expensive and time-consuming. Methods like Molecular Beam Epitaxy (MBE) offer precision but are too slow for mass production. On the other hand, faster methods like Metal-Organic Chemical Vapor Deposition (MOCVD) require significant investment in equipment and materials.

You can address scalability challenges by optimizing growth processes and exploring hybrid methods. Automation and AI-driven systems also play a role in reducing costs and improving efficiency. Despite these advancements, balancing quality and affordability remains a key hurdle.

Did you know? The cost of epitaxial growth often depends on the type of substrate and the complexity of the material being grown.

Substrate Compatibility

The choice of substrate is critical in epitaxial growth. Not all materials are compatible, and mismatches can lead to defects or poor performance. For instance, growing a material with a different lattice constant than the substrate can create strain, affecting the final product’s quality.

To overcome this, you need to select substrates with properties that match your desired material. Techniques like buffer layers can also help bridge the gap between incompatible materials. However, finding the right combination of substrate and growth method requires extensive research and experimentation.

Note: Substrate compatibility is a major factor in determining the success of epitaxial growth for advanced applications.

Future Directions and Applications

Quantum Materials

Epitaxial growth is unlocking the potential of quantum materials, which are essential for next-generation technologies. These materials exhibit unique properties, such as superconductivity and topological states, that you can harness for advanced applications. By using epitaxy, you can create ultra-pure layers with precise atomic arrangements, which are critical for quantum devices.

For example, you might use epitaxial techniques to grow materials like topological insulators or quantum dots. These materials are vital for quantum computing, where they enable faster and more secure data processing. Additionally, epitaxy allows you to stack layers of different materials, creating heterostructures that enhance quantum effects.

Tip: If you’re exploring quantum materials, focus on controlling defects during growth. Even minor imperfections can disrupt quantum behavior.

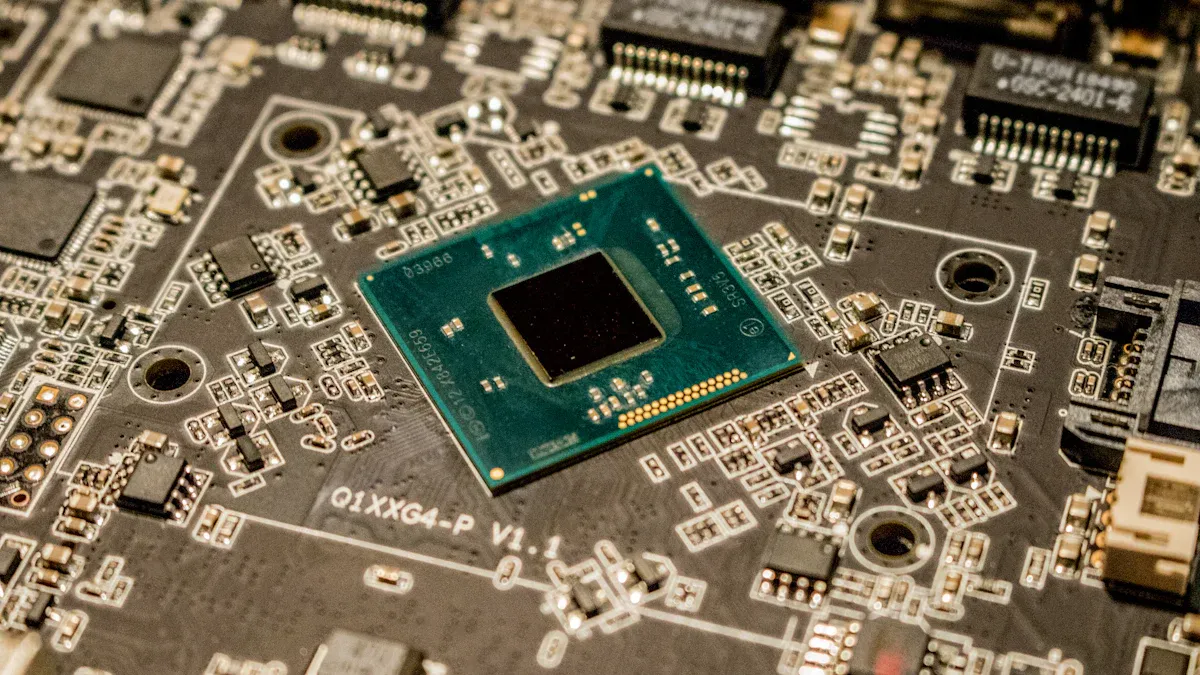

Next-Generation Semiconductors

The future of semiconductors depends on epitaxial growth. As devices become smaller and more powerful, you need materials with exceptional electrical properties. Epitaxy enables you to grow thin films with unmatched precision, making it a cornerstone for next-generation semiconductors.

One exciting area is the development of compound semiconductors, such as gallium nitride (GaN) and silicon carbide (SiC). These materials outperform traditional silicon in high-power and high-frequency applications. Through epitaxy, you can produce these semiconductors with the quality needed for 5G networks, electric vehicles, and advanced sensors.

You can also use epitaxy to integrate different materials on a single chip. This approach, known as heterogeneous integration, allows you to combine the best properties of various semiconductors. It opens the door to innovations like photonic chips, which use light instead of electricity for data transmission.

Did you know? Epitaxy is driving the shift from silicon-based technology to more advanced materials, ensuring the continued evolution of electronics.

Renewable Energy Technologies

Epitaxial growth is playing a pivotal role in renewable energy technologies. By enabling the production of high-efficiency materials, it helps you create devices that generate and store energy more effectively. Solar cells, for instance, benefit greatly from epitaxy. You can grow thin films of materials like gallium arsenide (GaAs), which achieve higher efficiencies than traditional silicon-based cells.

In addition to solar energy, epitaxy is advancing battery technology. Solid-state batteries, which are safer and more efficient than conventional ones, rely on epitaxial layers for their solid electrolytes. These layers ensure better ion conductivity and stability, improving overall performance.

You might also explore epitaxy for hydrogen production. Materials grown through epitaxy can serve as catalysts in water-splitting reactions, a key process for generating clean hydrogen fuel. This application highlights how epitaxy contributes to a sustainable energy future.

Note: Renewable energy technologies are becoming more efficient and accessible, thanks to advancements in epitaxial growth techniques.

Epitaxial growth stands as a cornerstone of material engineering, enabling you to create advanced materials with unmatched precision. Emerging trends like AI-optimized epitaxy and 2D materials are reshaping possibilities, while challenges such as defect control and scalability push innovation further.

Key Takeaway: Epitaxial techniques are not just tools—they are gateways to breakthroughs in quantum computing, renewable energy, and next-generation semiconductors.

By mastering these methods, you contribute to shaping technologies that define the future. The potential of epitaxial growth is vast, and its impact will continue to transform industries worldwide.

FAQ

What is epitaxial growth, and why is it important?

Epitaxial growth refers to the process of growing a crystal layer on a substrate with a matching structure. It’s important because it allows you to create materials with precise atomic arrangements, enabling advancements in semiconductors, photonics, and quantum technologies.

How does epitaxy differ from other crystal growth methods?

Epitaxy focuses on aligning the crystal structure of the grown layer with the substrate. Unlike other methods, it ensures superior material quality and properties, making it ideal for high-performance applications like microelectronics and optoelectronics.

Can epitaxial techniques be used for renewable energy?

Yes! Epitaxial growth helps you create high-efficiency materials for solar cells, solid-state batteries, and hydrogen production. These applications contribute to cleaner energy solutions and support the transition to sustainable technologies.

Tip: Explore gallium arsenide (GaAs) solar cells for their exceptional efficiency compared to traditional silicon cells.

What role does AI play in epitaxial growth?

AI optimizes growth conditions by analyzing data and predicting the best parameters. It helps you reduce defects, improve efficiency, and accelerate material development. AI-driven epitaxy is transforming industries by enabling faster innovation.

Are there challenges in scaling epitaxial growth?

Scaling epitaxial growth can be costly and time-consuming. Precision methods like MBE are slow, while scalable techniques like MOCVD require significant investment. You can address these challenges by adopting hybrid methods and leveraging automation.

Did you know? Hybrid techniques combine precision and scalability, making them ideal for industrial applications.