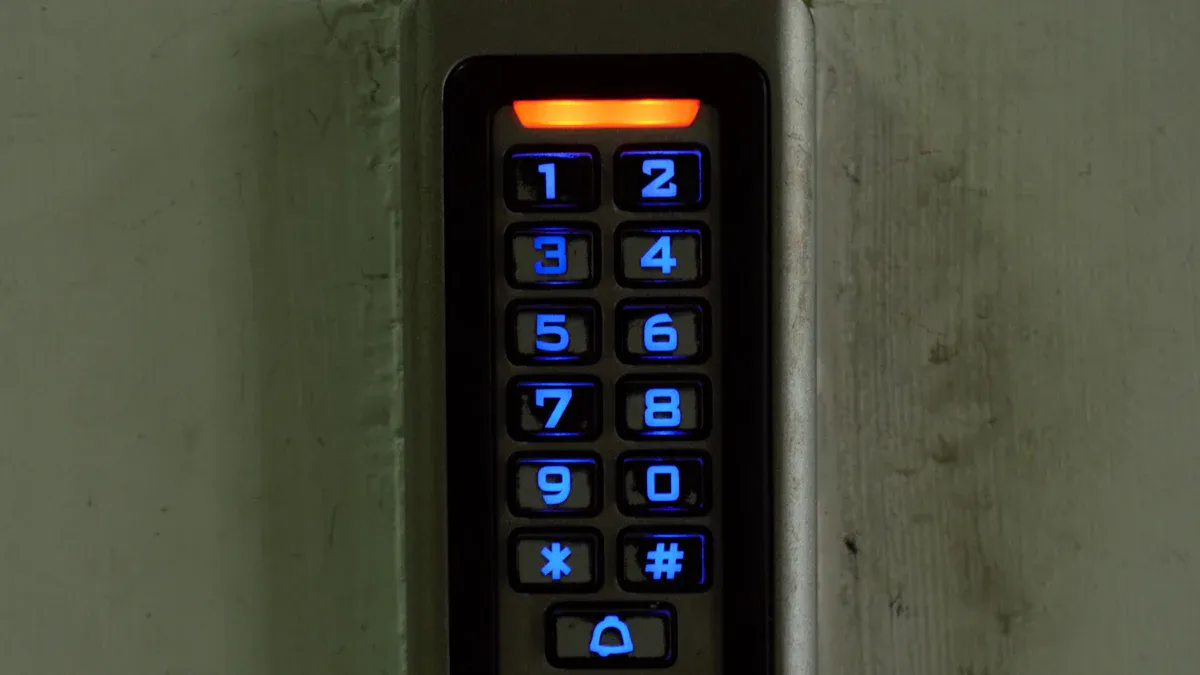

Selecting the right Industrial Illuminated Keypad requires you to check durability, visibility, and resistance to harsh environments. You should match keypad materials, such as a Zinc Alloy Illuminated Keypad, to your workspace. Consider user needs, lighting conditions, and the type of equipment for smooth operation.

Key Takeaways

- Match keypad features like backlighting, durability, and user interaction to your specific work environment and needs for the best performance.

- Choose keypads made from strong materials with high protection ratings to ensure long life and reliable use in harsh or demanding conditions.

- Look for customizable options and certified products to fit your application perfectly and guarantee safety and quality.

Industrial Illuminated Keypad: Key Selection Criteria

Matching Features to Application Requirements

You need to match the features of an Industrial Illuminated Keypad to your specific application. Start by listing your operational needs. Do you require the keypad to work in low-light conditions? Will users wear gloves? Does your environment expose equipment to dust, water, or chemicals? Each answer helps you narrow your choices.

- Lighting Needs: Choose keypads with adjustable backlighting if your workspace has changing light levels. Some models offer multi-color LEDs for status indication.

- User Interaction: Select keypads with large, tactile buttons if users wear gloves. For clean rooms or food processing, smooth surfaces help with sanitation.

- Environmental Demands: Look for keypads with high IP or NEMA ratings if you face moisture, dust, or extreme temperatures.

Tip: Make a checklist of your requirements before you compare keypad models. This step saves time and ensures you do not overlook critical features.

Here is a simple table to help you align features with your application:

| Application Need | Recommended Feature |

|---|---|

| Low-light operation | Bright, adjustable backlighting |

| Outdoor use | Weatherproof, UV-resistant housing |

| High-traffic area | Durable, vandal-resistant design |

| Clean environments | Sealed, easy-to-clean surfaces |

Evaluating Performance and Reliability

You want your Industrial Illuminated Keypad to perform well and last long. Performance depends on how the keypad responds to user input and how it handles repeated use.

- Tactile Feedback: Choose keypads that give clear feedback when pressed. This reduces errors and improves user confidence.

- Lifespan: Check the rated number of actuations. Industrial keypads often last for millions of cycles.

- Resistance: Make sure the keypad resists chemicals, water, and dust if your environment demands it.

- Power Efficiency: Some keypads use low-power LEDs to save energy, which is important for battery-powered systems.

Note: Always ask for test reports or certifications from the manufacturer. These documents prove the keypad meets industry standards for reliability.

You can use this checklist to evaluate keypad performance:

- Does the keypad respond quickly to every press?

- Can it withstand frequent cleaning or harsh chemicals?

- Will the backlighting remain bright over time?

- Is the keypad rated for the temperature range in your facility?

By focusing on these criteria, you ensure your Industrial Illuminated Keypad will meet your needs and deliver reliable performance in your application.

Types of Industrial Illuminated Keypad and Operating Mechanisms

Membrane Keypads with Backlighting

You often see membrane keypads in control panels and machinery. These keypads use thin, flexible layers to register a press. Manufacturers add backlighting by placing LEDs or light guides behind the keys. This design helps you see the keys in dark or dim areas. Membrane keypads resist water and dust, making them a good choice for harsh environments. You can clean them easily because the surface is flat and sealed.

Tip: Choose membrane keypads if you need a cost-effective solution with simple cleaning and reliable backlighting.

Mechanical Keypads with LED Illumination

Mechanical keypads use individual switches under each key. You get strong tactile feedback with every press. LED illumination sits under each keycap, so you see bright and clear symbols. These keypads last a long time and handle heavy use. You often find them in places where users press keys many times each day. You can replace keycaps or switches if needed.

- Mechanical keypads offer:

- High durability

- Customizable lighting

- Easy maintenance

Capacitive and Piezo Keypads

Capacitive keypads sense your touch without moving parts. You only need to touch the surface to activate a key. Piezo keypads use pressure sensors and also have no moving parts. Both types work well in tough environments. You can use them in places with chemicals, moisture, or extreme temperatures. These keypads often last longer than other types because nothing wears out.

Note: If you need an Industrial Illuminated Keypad for outdoor or public use, capacitive and piezo options give you the best resistance to damage and weather.

Industrial Illuminated Keypad Features and Specifications

Backlighting Options and Light Guides

You need to see the keys clearly in every condition. Backlighting helps you use the keypad in dark or low-light areas. Manufacturers offer several backlighting options, such as single-color LEDs, multi-color LEDs, and fiber optic light guides. You can choose a keypad with uniform lighting or select models with individual key illumination. Some keypads let you adjust the brightness or change the color to show different statuses.

Tip: Use multi-color backlighting if you want to show system status or alerts directly on the keypad.

Light guides help spread the light evenly across the keys. This design prevents dark spots and makes every symbol easy to read. You should check if the keypad uses high-quality light guides for the best visibility.

Durability, Lifespan, and Environmental Resistance

You want your keypad to last for years, even in tough conditions. Industrial keypads use strong materials like stainless steel, zinc alloy, or high-grade plastics. These materials resist impacts, scratches, and wear. Manufacturers test keypads for millions of presses to ensure long life.

You should also look for keypads with high IP or NEMA ratings. These ratings show the keypad can block dust, water, and other hazards. Some keypads work in extreme temperatures or resist chemicals. If you use the keypad outdoors or in a factory, pick a model with proven environmental resistance.

| Feature | Benefit |

|---|---|

| Stainless steel body | High impact resistance |

| Sealed design | Blocks dust and water |

| UV-resistant coating | Prevents sun damage |

| Chemical resistance | Withstands cleaning agents |

Tactile Feedback and User Experience

You need to feel confident when you press a key. Tactile feedback gives you a clear response with every press. Mechanical keypads offer a strong click, while membrane keypads provide a softer touch. Capacitive and piezo keypads do not move, but some models use sound or vibration to signal activation.

A good user experience means fewer mistakes and faster operation. You should test different keypads to find the feedback that feels best for your application. If users wear gloves, choose keys with a larger surface and stronger feedback.

Note: Tactile feedback improves speed and accuracy, especially in busy or noisy environments.

Customization, Layout, and Programmability

Every application has unique needs. You can customize the layout, size, and shape of your keypad. Some manufacturers let you choose the number of keys, the symbols, and the colors. You can add company logos or special legends for easy identification.

Programmable keypads let you assign different functions to each key. You can set up shortcuts or macros to speed up tasks. This flexibility helps you create a keypad that fits your workflow.

- Customization options include:

- Key size and spacing

- Legend and symbol design

- Backlight color and brightness

- Special function keys

Electrical Interface and System Compatibility

You must connect the keypad to your system easily. Industrial keypads support many electrical interfaces, such as USB, PS/2, matrix, or serial connections. Some models use standard connectors, while others offer custom wiring.

You should check if the keypad matches your control system or device. Compatibility ensures smooth installation and reliable operation. Some keypads also support communication protocols like I2C or CAN bus for advanced integration.

Alert: Always verify the electrical interface before you order a keypad. This step prevents costly mistakes during installation.

Design and Material Considerations for Industrial Illuminated Keypad

Housing Materials and Surface Finishes

You need to choose the right housing material for your keypad. Stainless steel offers strong protection against impacts and corrosion. Zinc alloy gives you a balance of strength and cost. High-grade plastics work well in less demanding settings. Surface finishes matter too. Brushed metal hides scratches. Glossy finishes look modern but show fingerprints. Matte surfaces reduce glare and help users see the keys in bright light.

Tip: Select a finish that matches your environment. For outdoor use, pick a surface that resists UV rays and weather.

Keytop, Legend, and Illumination Design

Keytop design affects how users interact with the keypad. Raised keys help users find buttons by touch. Flat keys make cleaning easier. Legends show the function of each key. Laser-etched legends last longer than printed ones. Backlit legends improve visibility in low light. You can choose different colors for illumination to match your system or highlight important keys.

| Keytop Type | Cleaning Ease | Tactile Feel |

|---|---|---|

| Raised | Moderate | Strong |

| Flat | Easy | Soft |

Mounting and Integration Methods

You must install the keypad securely. Panel mount keypads fit into cutouts on control panels. Rear mount options hide screws for a clean look. Some keypads use adhesive backing for quick installation. Others use brackets or studs for extra strength. Always check the mounting method before you buy. This step ensures the keypad fits your equipment.

Note: Proper mounting prevents damage and keeps the keypad stable during use.

Standards and Certifications for Industrial Illuminated Keypad

IP and NEMA Ratings

You need to check the IP (Ingress Protection) and NEMA (National Electrical Manufacturers Association) ratings when you choose an industrial illuminated keypad. These ratings show how well the keypad resists dust, water, and other hazards. An IP rating uses two numbers. The first number shows protection against solids like dust. The second number shows protection against liquids like water. For example, IP65 means the keypad is dust-tight and can resist water jets.

NEMA ratings work in a similar way but use a different system. NEMA 4 and NEMA 4X are common for outdoor or washdown areas. NEMA 4X also protects against corrosion. You can use this table to compare the ratings:

| Rating | Protection Level | Typical Use |

|---|---|---|

| IP65 | Dust-tight, water jets | Factories, outdoors |

| NEMA 4 | Windblown dust, rain, splash | Industrial panels |

| NEMA 4X | Same as 4 + corrosion | Food, marine, outdoor |

Tip: Always match the rating to your environment. Higher ratings mean better protection.

Compliance with UL, CE, and RoHS

You should look for keypads that meet important safety and environmental standards. UL (Underwriters Laboratories) tests products for safety in the United States. CE marking shows the keypad meets European safety and health rules. RoHS (Restriction of Hazardous Substances) means the keypad does not use harmful materials like lead or mercury.

- UL: Ensures electrical safety.

- CE: Confirms compliance with European laws.

- RoHS: Protects users and the environment from toxic substances.

Alert: Ask your supplier for certificates. These documents prove the keypad meets all required standards. You protect your equipment and your team by choosing certified products.

Application-Specific Recommendations for Industrial Illuminated Keypad

Solutions for Harsh and Outdoor Environments

You face tough conditions in outdoor or industrial settings. Rain, dust, and extreme temperatures can damage ordinary keypads. Choose models with high IP or NEMA ratings for the best protection. Stainless steel or zinc alloy housings resist corrosion and impacts. Sealed designs keep out water and dirt. UV-resistant coatings prevent sun damage. For outdoor use, select keypads with bright, adjustable backlighting. This feature helps users see keys in direct sunlight or at night.

Tip: Always check the temperature range and chemical resistance before you install a keypad outside.

Keypads for High-Use and Public Access Areas

Public spaces and busy workstations demand keypads that last. You need vandal-resistant designs with reinforced housings. Mechanical keypads with metal keytops handle frequent use. Laser-etched legends stay readable after thousands of presses. Look for models with replaceable keycaps for easy maintenance. Rounded edges and smooth surfaces help prevent tampering.

- Key features for public access:

- High actuation lifespan

- Tamper-proof mounting

- Easy-to-clean surfaces

Specialized Equipment and Security Applications

Specialized equipment often requires custom layouts and advanced security. You can choose keypads with programmable keys for unique functions. Backlit legends improve visibility in low-light areas. For security, select models with encrypted communication or PIN entry features. Some keypads offer tactile or audible feedback for confirmation. Custom legends and colors help users avoid mistakes.

Note: Work with your supplier to design a keypad that matches your equipment and security needs.

Real-World Examples of Industrial Illuminated Keypad Selection

Manufacturing Plant Case Study

You work in a busy manufacturing plant. Machines run all day, and workers wear gloves. You need a keypad that stands up to heavy use and harsh cleaning. You choose a stainless steel keypad with high IP rating. The keys have strong tactile feedback, so workers know when they press a button. Bright backlighting helps everyone see the keys, even in low light. The sealed design keeps out dust and water. You notice fewer errors and less downtime after installing this keypad.

Tip: Always test the keypad with gloves before you buy. This step ensures the best fit for your team.

Outdoor Kiosk Case Study

You manage outdoor kiosks in a city park. Weather changes fast, and people use the kiosks day and night. You select a vandal-resistant keypad with UV protection. The housing resists rain, sun, and even graffiti. Adjustable backlighting makes the keys easy to read at any hour. The keypad mounts securely to prevent tampering. You see the kiosks stay in good shape, and users find them easy to use.

Medical Equipment Case Study

You design equipment for hospitals. Cleanliness and safety matter most. You pick a flat, sealed keypad with smooth surfaces. The legends use laser etching, so they do not fade after cleaning. Soft backlighting helps staff work in dim rooms. The keypad resists chemicals and frequent disinfection. Nurses and doctors report that the keys feel comfortable and easy to press.

You now understand how to evaluate features, match them to your environment, and check certifications. Start by listing your requirements. Compare options, request samples, and consult suppliers. This approach helps you select the best keypad for your application.

Tip: Always test keypads in real conditions before finalizing your choice.

FAQ

What is the typical lifespan of an industrial illuminated keypad?

You can expect most industrial illuminated keypads to last for millions of actuations. Manufacturers often rate them for over 1,000,000 key presses.

Can you clean illuminated keypads with harsh chemicals?

You should check the keypad’s material and rating. Many industrial keypads resist chemicals, but always confirm compatibility with your cleaning agents.

How do you choose the right backlighting color?

You should select a color that matches your environment and improves visibility. Some keypads offer multi-color LEDs for status indication or user preference.