Achieving uniform deposition in GaN production requires precise control over critical factors. Custom EPI susceptor designs optimize temperature distribution and gas flow, ensuring consistent results. These designs also improve wafer placement, reducing defects. By adopting tailored solutions, you can enhance production efficiency and elevate the quality of GaN-based devices.

Key Takeaways

- Special EPI susceptor designs control heat and gas flow better. This helps make GaN layers even during production.

- Using custom designs lowers mistakes and makes GaN devices better. This keeps customers happier with the products.

- Custom solutions keep wafers steady, even for bigger ones. This improves results and speeds up production.

Importance of Uniform Deposition in GaN Production

Impact on GaN Device Performance and Reliability

Uniform deposition plays a vital role in determining the performance and reliability of GaN-based devices. When the material layers are evenly deposited, the electrical and thermal properties of the device improve significantly. This consistency ensures that the device operates efficiently under various conditions. For example, LEDs with uniform deposition emit light more evenly, resulting in better brightness and color accuracy. Similarly, power electronics benefit from reduced energy losses and enhanced thermal stability.

Inconsistent deposition, on the other hand, can lead to defects such as cracks, voids, or uneven thickness. These issues compromise the device’s performance and shorten its lifespan. You might notice that devices with poor deposition quality fail to meet industry standards or customer expectations. By focusing on uniform deposition, you can ensure that your GaN devices deliver optimal performance and maintain reliability over time.

Challenges in Achieving Uniform Deposition with Standard Susceptors

Standard susceptors often fall short when it comes to achieving uniform deposition. These designs lack the precision needed to control temperature distribution and gas flow dynamics effectively. As a result, you may encounter uneven heating across the wafer surface, leading to inconsistent material growth. This issue becomes more pronounced in larger wafers, where maintaining uniformity is even more challenging.

Another common problem with standard susceptors is wafer instability. Without proper support and alignment, wafers can shift during the deposition process. This movement disrupts the uniformity of the material layers, increasing the likelihood of defects. Additionally, standard susceptors may not use advanced materials or coatings that enhance thermal management. This limitation can cause overheating or uneven cooling, further affecting deposition quality.

To overcome these challenges, you need to consider custom solutions. Custom EPI Susceptor designs address these issues by optimizing key factors such as temperature control, gas flow, and wafer placement. These tailored designs ensure that you achieve consistent results, even in demanding production environments.

Role of Custom EPI Susceptor Designs

Design Features Optimizing Temperature and Gas Flow

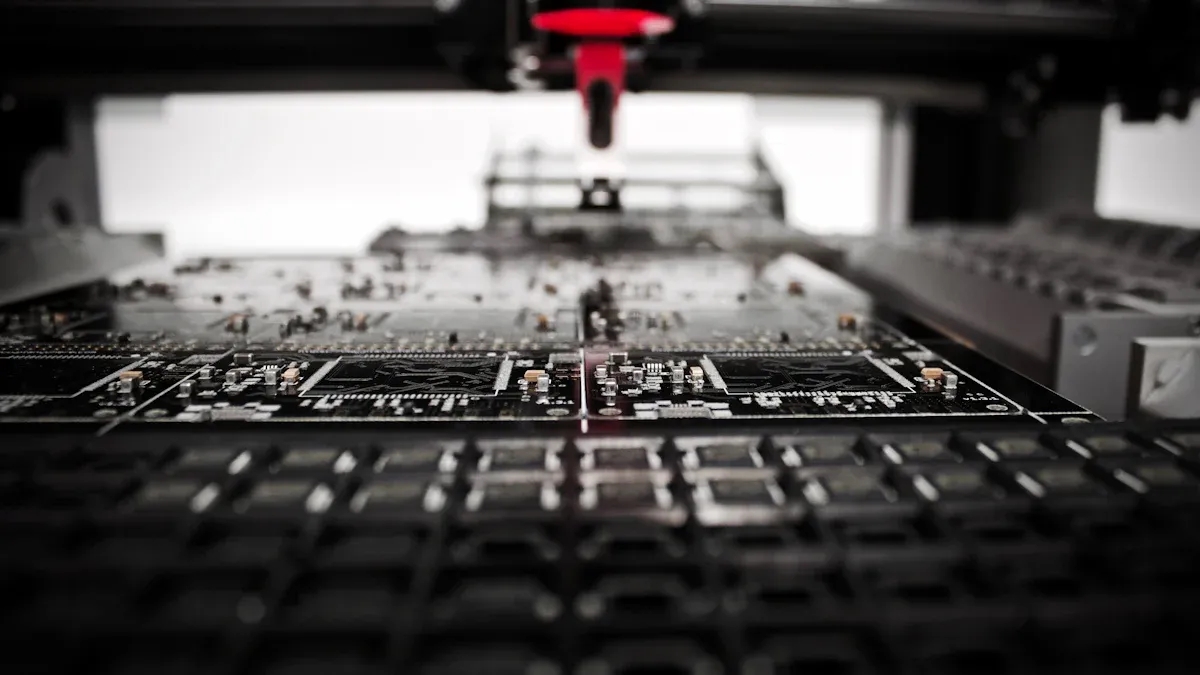

Custom EPI Susceptor designs play a critical role in controlling temperature and gas flow during GaN production. These designs ensure that heat is distributed evenly across the wafer surface, preventing hot spots or cold zones. You can achieve this by using susceptors with advanced geometries that promote uniform thermal conductivity. For example, some designs include grooves or channels that guide the flow of gases, ensuring consistent exposure to the wafer.

Gas flow optimization is equally important. Uneven gas distribution can lead to irregular deposition, affecting the quality of the final product. Custom susceptors often feature strategically placed vents or openings that regulate the flow of gases. This ensures that the chemical precursors used in the deposition process reach every part of the wafer uniformly. By addressing these factors, you can significantly improve the consistency of GaN layer growth.

Tip: When selecting a custom EPI Susceptor, prioritize designs that balance thermal management and gas flow dynamics. This combination is key to achieving uniform deposition.

Enhanced Wafer Placement and Stability

Wafer placement is another critical factor in GaN production. Custom EPI Susceptor designs provide enhanced stability, ensuring that wafers remain securely positioned throughout the deposition process. This stability minimizes the risk of movement or misalignment, which can lead to defects in the material layers.

Some custom designs incorporate features like recessed pockets or clamps to hold the wafer in place. These features prevent shifting caused by vibrations or gas flow turbulence. Additionally, optimized wafer placement ensures that the wafer surface remains parallel to the susceptor, promoting uniform deposition across the entire area.

You can also benefit from designs that accommodate wafers of various sizes. Larger wafers often face greater challenges in maintaining uniformity, but custom susceptors can address this by offering tailored support structures. This adaptability makes custom designs a valuable asset for manufacturers aiming to scale up production.

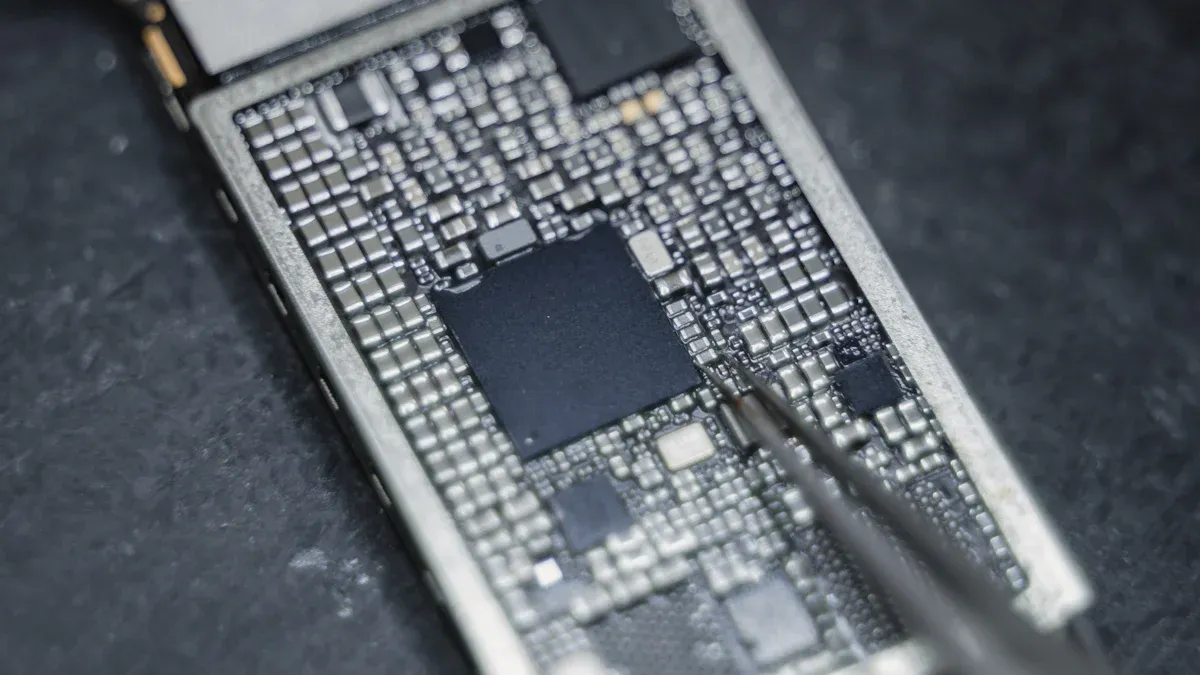

Advanced Materials and Coatings for Thermal Management

The materials and coatings used in custom EPI Susceptor designs are essential for effective thermal management. High-performance materials like graphite or silicon carbide are commonly used due to their excellent thermal conductivity and durability. These materials help maintain consistent temperatures during the deposition process, reducing the risk of overheating or uneven cooling.

Specialized coatings further enhance thermal management. For instance, reflective coatings can minimize heat loss by redirecting thermal energy back toward the wafer. Anti-corrosion coatings protect the susceptor from chemical damage, extending its lifespan and maintaining its performance over time.

Note: Advanced materials and coatings not only improve deposition uniformity but also reduce maintenance costs. Investing in high-quality susceptors can save you time and resources in the long run.

Benefits of Custom EPI Susceptor Designs

Improved Deposition Uniformity and Reduced Defects

Custom EPI Susceptor designs significantly improve deposition uniformity. By optimizing temperature distribution and gas flow, these designs ensure that material layers grow evenly across the wafer. This uniformity reduces the likelihood of defects such as cracks or uneven thickness. When you use a custom susceptor, you can achieve higher-quality GaN layers, which directly enhances the performance of your devices.

Defect reduction also means fewer rejected wafers. This improvement saves time and resources, allowing you to focus on scaling production. With fewer defects, your devices meet industry standards more consistently, boosting customer satisfaction and trust in your products.

Tip: Investing in a custom EPI Susceptor can help you minimize production errors and improve overall device quality.

Higher Production Yields and Cost Efficiency

Custom designs not only improve quality but also increase production yields. When deposition is uniform, more wafers meet the required specifications. This consistency reduces waste and maximizes the number of usable devices per production cycle. You can achieve higher output without compromising quality.

Cost efficiency is another advantage. By reducing defects and waste, you lower the cost per unit. Custom susceptors also require less maintenance due to their advanced materials and coatings. Over time, these savings add up, making your production process more profitable.

Real-World Applications in LEDs and Power Electronics

The benefits of custom EPI Susceptor designs extend to real-world applications. In LED manufacturing, uniform deposition ensures consistent brightness and color accuracy. This precision is essential for high-performance lighting solutions. Power electronics also benefit from improved thermal stability and energy efficiency, which are critical for devices like inverters and chargers.

Custom susceptors enable you to meet the demanding requirements of these industries. By adopting tailored solutions, you can produce devices that perform reliably in various applications, from consumer electronics to industrial systems.

Custom EPI susceptor designs are essential for achieving uniform deposition in GaN production. They help you overcome challenges like uneven temperature distribution and wafer instability. These designs improve manufacturing efficiency and enhance device performance. By adopting tailored solutions, you can optimize your production process and deliver high-quality GaN-based devices.

FAQ

What makes custom EPI susceptor designs better than standard ones?

Custom designs optimize temperature, gas flow, and wafer stability. These features ensure uniform deposition, reduce defects, and improve the quality of GaN-based devices. 🛠️

How do custom susceptors improve production efficiency?

They reduce defects and waste, leading to higher yields. Advanced materials and coatings also lower maintenance needs, saving you time and costs in the long run. 💡

Can custom susceptors handle larger wafers?

Yes, custom designs accommodate various wafer sizes. Tailored support structures ensure stability and uniform deposition, even for larger wafers used in high-volume production. 📏