Maintaining graphite susceptors plays a vital role in ensuring contamination-free epitaxial (EPI) processes. Contamination reduces wafer quality and increases production costs. It also disrupts the integrity of epitaxial growth. You can avoid these issues by adopting consistent maintenance practices. Proactive care keeps your equipment performing optimally and safeguards your manufacturing outcomes.

Key Takeaways

- Clean graphite susceptors often to keep them in good shape. Use soft tools and follow the maker’s instructions to avoid harm.

- Check susceptors regularly to find dirt or problems early. Make a plan to look for buildup or uneven surfaces.

- Follow cleanroom rules to stop outside dirt from spreading. Keep the air dry and wear safety gear to protect susceptors.

Understanding Graphite Susceptors in EPI Processes

What Are Graphite Susceptors?

Graphite susceptors are critical components in epitaxial (EPI) processes. These are specially designed structures made from high-purity graphite. Their primary purpose is to support wafers during the deposition process. The unique properties of graphite, such as its thermal stability and electrical conductivity, make it an ideal material for this application. You will often find these susceptors coated with silicon carbide (SiC) to enhance their durability and performance.

Role of Graphite Susceptors in EPI Processes

In EPI processes, graphite susceptors play a vital role in ensuring uniform epitaxial growth. They provide a stable platform for wafers, maintaining precise temperature control during deposition. This stability ensures that the thin films deposited on the wafer are even and defect-free. Without a properly functioning susceptor, achieving high-quality epitaxial layers becomes challenging. You rely on these components to maintain the integrity of your wafers and the overall efficiency of your production line.

Why Graphite Susceptors Are Prone to Contamination

Graphite susceptors face contamination risks due to their exposure to high temperatures and reactive gases during EPI processes. Particle buildup on their surfaces can occur over time, affecting their performance. Additionally, chemical residues from deposition materials may adhere to the susceptor, leading to defects in the wafers. Environmental factors, such as moisture, can also contribute to contamination. Regular maintenance helps you mitigate these risks and extend the lifespan of your susceptors.

Common Sources of Contamination

Particle Buildup on Susceptor Surfaces

Particle buildup is one of the most common contamination issues you may face with a graphite susceptor. During EPI processes, particles from deposition materials or external sources can settle on the susceptor’s surface. These particles interfere with the uniformity of the epitaxial layer, leading to defects in the wafer. Over time, this buildup can also reduce the thermal efficiency of the susceptor, affecting its performance. Regular cleaning and inspection help you address this issue before it impacts production quality.

Chemical Residues from Deposition Processes

Chemical residues left behind during deposition processes pose another significant contamination risk. These residues often result from incomplete reactions or leftover materials that adhere to the susceptor’s surface. If not removed, they can alter the chemical environment during subsequent processes, leading to inconsistent results. You can prevent this by implementing thorough cleaning protocols after each production cycle. Using advanced cleaning techniques, such as plasma cleaning or chemical etching, ensures that stubborn residues are effectively eliminated.

Environmental Factors and Moisture Control

Environmental factors, including moisture, can also contribute to contamination. Graphite susceptors are sensitive to humidity, which can cause unwanted reactions with deposition materials. Additionally, airborne contaminants in the production environment may settle on the susceptor, further increasing the risk of defects. To minimize these risks, you should maintain strict environmental controls, such as using cleanrooms and monitoring humidity levels. Proper storage of susceptors in controlled conditions also helps prevent contamination when they are not in use.

Best Practices for Graphite Susceptor Maintenance

Regular Cleaning Protocols and Flushing Procedures

Keeping your graphite susceptor clean is essential for maintaining its performance. Regular cleaning protocols help remove particle buildup and chemical residues that accumulate during EPI processes. Start by using non-abrasive tools and cleaning agents specifically designed for graphite materials. These tools prevent surface damage while effectively removing contaminants.

Flushing procedures are another critical step. Use high-purity gases or liquids to flush the susceptor’s surface after each production cycle. This process eliminates residual particles and ensures the susceptor is ready for the next operation. For stubborn residues, advanced techniques like plasma cleaning or chemical etching may be necessary. Consistent cleaning routines not only improve wafer quality but also extend the lifespan of your equipment.

Tip: Always follow the manufacturer’s recommendations for cleaning agents and procedures to avoid damaging the susceptor.

Inspection Schedules for Early Detection of Contamination

Frequent inspections allow you to identify contamination before it affects production. Create a detailed inspection schedule that includes visual checks and advanced diagnostic methods. Look for signs of particle buildup, discoloration, or surface irregularities. These issues often indicate contamination or wear.

Use tools like microscopes or surface analyzers to detect microscopic defects. Early detection helps you address problems before they escalate, saving time and reducing costs. Document your findings during each inspection. This record helps you track trends and identify recurring issues, enabling you to refine your maintenance practices.

Note: Regular inspections not only prevent contamination but also ensure your graphite susceptor operates at peak efficiency.

Proper Handling and Storage in Controlled Environments

How you handle and store your graphite susceptor significantly impacts its performance. Always use clean, lint-free gloves when handling the susceptor to avoid transferring oils or particles. Avoid dropping or scratching the susceptor, as physical damage can compromise its functionality.

Store the susceptor in a controlled environment when not in use. Use cleanrooms or sealed containers to protect it from airborne contaminants and moisture. Maintaining a stable temperature and humidity level in the storage area further reduces the risk of contamination. Proper handling and storage practices ensure your susceptor remains in optimal condition for longer periods.

Reminder: Mishandling or improper storage can lead to contamination and reduce the efficiency of your EPI processes.

Advanced Cleaning Techniques for Graphite Susceptors

Plasma Cleaning for Effective Particle Removal

Plasma cleaning is one of the most efficient methods for removing particles from your graphite susceptor. This technique uses ionized gas, or plasma, to dislodge contaminants from the susceptor’s surface. The plasma generates high-energy ions that break the bonds between particles and the surface, effectively cleaning even the smallest debris.

You can use plasma cleaning to target specific areas without damaging the susceptor. It works well for removing organic residues, dust, and other microscopic particles that traditional cleaning methods might miss. This process also prepares the susceptor for the next production cycle by ensuring a clean, smooth surface.

Tip: Use plasma cleaning regularly to maintain the thermal efficiency and performance of your graphite susceptor.

Chemical Etching for Stubborn Residues

Chemical etching is a powerful solution for removing stubborn residues that plasma cleaning cannot handle. This method involves applying a chemical solution to dissolve contaminants on the susceptor’s surface. The chemicals react with the residues, breaking them down and leaving the surface clean and ready for use.

You should choose etching solutions carefully to avoid damaging the susceptor. Always follow the manufacturer’s guidelines for chemical compatibility. Chemical etching is particularly effective for removing metallic or inorganic residues that accumulate during deposition processes.

Note: Wear proper protective equipment when handling etching chemicals to ensure safety.

Baking and Thermal Cleaning to Reduce Metal Contamination

Baking and thermal cleaning are excellent techniques for reducing metal contamination on your graphite susceptor. This process involves heating the susceptor to high temperatures in a controlled environment. The heat causes contaminants, such as metal residues, to evaporate or oxidize, leaving the surface clean.

Thermal cleaning is especially useful for removing impurities that are deeply embedded in the susceptor. It also helps restore the susceptor’s original properties, such as thermal stability and conductivity. You can combine this method with other cleaning techniques for even better results.

Reminder: Monitor the temperature closely during thermal cleaning to prevent damage to the susceptor.

Preventive Measures to Minimize Contamination

Using SiC-Coated Graphite Susceptors for Enhanced Performance

Silicon carbide (SiC) coatings significantly improve the performance of your graphite susceptor. These coatings create a protective barrier that resists chemical reactions and reduces particle buildup. SiC-coated susceptors also offer better thermal stability, ensuring consistent temperature control during epitaxial processes. By using these enhanced susceptors, you minimize contamination risks and extend the lifespan of your equipment. Always verify the quality of the coating before use to ensure optimal results.

Ensuring Complete Coating Coverage to Prevent Corrosion

Incomplete coating coverage can expose the graphite base to reactive gases and chemicals. This exposure leads to corrosion, which compromises the susceptor’s performance and increases contamination risks. You should inspect the coating for uniformity and address any gaps or defects immediately. Regular checks help you maintain the integrity of the coating, ensuring the susceptor remains resistant to wear and contamination. Proper maintenance of the coating also reduces the need for frequent replacements, saving you time and resources.

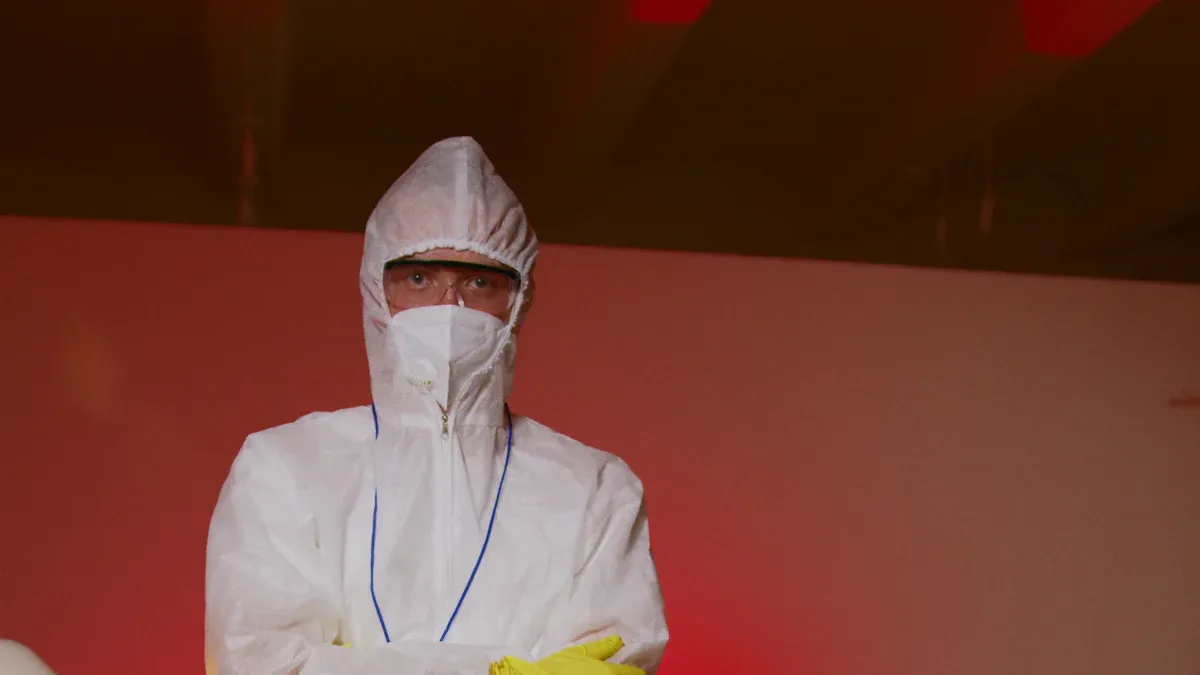

Implementing Cleanroom and Gowning Procedures

Maintaining a clean production environment is essential for preventing contamination. You should implement strict cleanroom protocols, including air filtration systems and humidity control. These measures reduce airborne particles and moisture that can settle on the susceptor. Additionally, gowning procedures, such as wearing gloves, masks, and cleanroom suits, prevent the transfer of oils and debris from personnel. Training your team on these protocols ensures consistent adherence, keeping your susceptors and wafers contamination-free.

Monitoring and Quality Assurance

Importance of Monitoring Contamination Levels

Monitoring contamination levels ensures your graphite susceptor performs optimally. Regular checks help you identify issues before they affect production quality. Use tools like particle counters or surface analyzers to measure contamination levels accurately. These devices provide real-time data, allowing you to take immediate corrective action.

Establish a baseline for acceptable contamination levels. Compare current readings to this baseline during inspections. If contamination exceeds the threshold, implement cleaning or maintenance procedures promptly. Monitoring contamination levels not only protects your equipment but also ensures consistent wafer quality.

Tip: Document contamination trends over time to predict potential risks and refine your maintenance schedule.

Quality Control Measures for Long-Term Effectiveness

Quality control measures keep your graphite susceptor in peak condition. Develop a checklist for routine inspections and cleaning tasks. Include steps like verifying coating integrity, checking for surface irregularities, and testing thermal performance.

Train your team to follow these procedures consistently. Proper training ensures everyone understands the importance of maintaining high standards. Use automated systems to track maintenance activities and generate reports. These systems help you identify gaps in your processes and improve overall efficiency.

Reminder: Consistent quality control reduces downtime and extends the lifespan of your equipment.

Leveraging Data to Optimize Maintenance Practices

Data plays a crucial role in optimizing your maintenance practices. Analyze inspection and cleaning records to identify recurring contamination patterns. Use this information to adjust your cleaning frequency or adopt advanced techniques like plasma cleaning.

Implement predictive maintenance tools that use data to forecast equipment needs. These tools help you address issues before they escalate, saving time and resources. By leveraging data, you can create a proactive maintenance strategy that minimizes contamination risks and maximizes production efficiency.

Note: Data-driven decisions improve both equipment reliability and wafer quality.

Maintaining graphite susceptors is essential for preventing contamination in EPI processes. Consistent cleaning, regular inspections, and proper handling ensure optimal performance. Advanced techniques, such as SiC coatings and cleanroom protocols, further reduce contamination risks.

Key Takeaway: Proactive maintenance safeguards wafer quality, reduces costs, and enhances production efficiency.

FAQ

What is the best way to clean a graphite susceptor?

Use non-abrasive tools and cleaning agents designed for graphite. Follow the manufacturer’s guidelines to avoid damage. For stubborn residues, consider plasma cleaning or chemical etching.

Tip: Regular cleaning prevents buildup and extends the susceptor’s lifespan.

How often should you inspect a graphite susceptor?

Inspect your susceptor after every production cycle. Look for discoloration, particle buildup, or surface irregularities. Early detection helps you address issues before they escalate.

Can environmental factors affect susceptor performance?

Yes, moisture and airborne particles can cause contamination. Use cleanrooms, control humidity, and store susceptors in sealed containers to minimize environmental risks.

Reminder: Proper storage ensures long-term performance and reduces contamination risks.