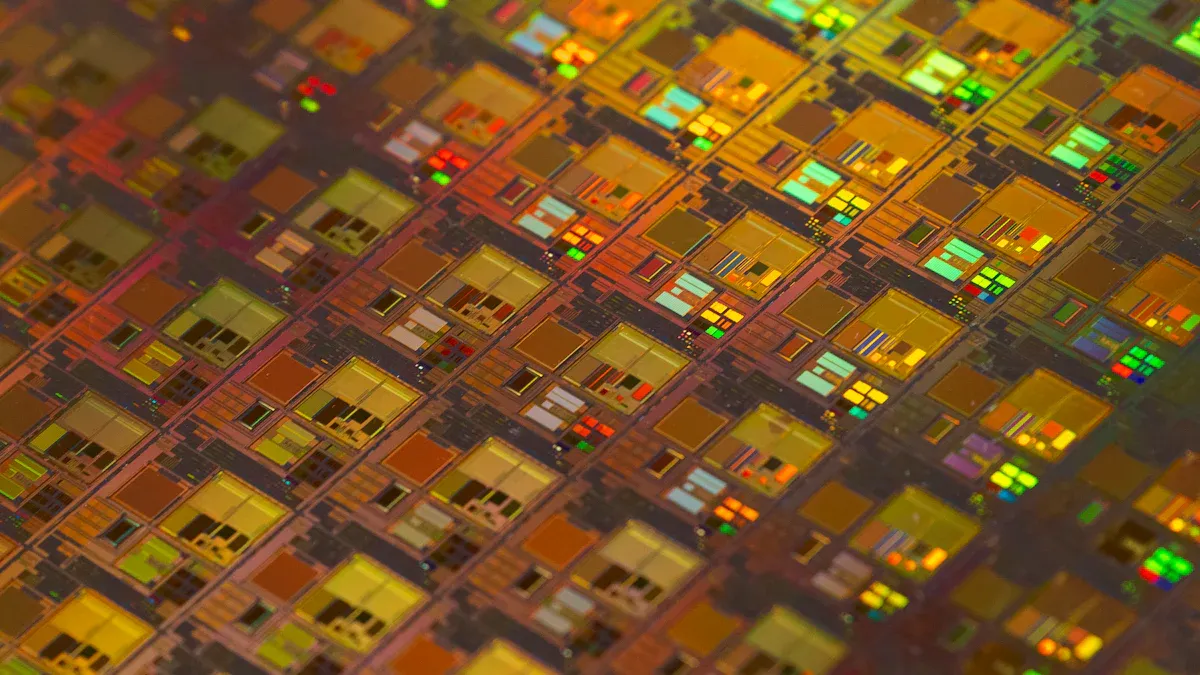

EPI SUSCEPTOR is a specialized component used in semiconductor production to support wafers during epitaxial growth. By incorporating an EPI SUSCEPTOR into your production line, you ensure precise thermal conductivity and uniformity, which enhances product quality and process efficiency. The successful use of an EPI SUSCEPTOR also minimizes production errors, providing a competitive advantage in manufacturing.

Key Takeaways

- Check your current production line first. Find any problems to stop issues later.

- Make sure it meets industry rules. This keeps it safe and makes it work better.

- Use a clear installation plan. Correct setup and safety steps are key to good results and avoiding harm.

Preparation and Assessment

Evaluating Current Production Line Capabilities

Before integrating an EPI SUSCEPTOR, you need to assess your current production line. Start by reviewing the equipment and processes already in place. Identify any limitations that could affect the integration. For example, check if your machinery can handle the thermal and mechanical requirements of an EPI SUSCEPTOR. Evaluate the software systems as well. Ensure they can support the additional controls and monitoring needed for the new component.

You should also analyze production data. Look for patterns or issues that might impact the performance of the EPI SUSCEPTOR. This step helps you understand where adjustments may be necessary. By thoroughly evaluating your production line, you can avoid unexpected challenges during the integration process.

Identifying Requirements for EPI Susceptor Integration

Once you understand your production line, define the specific requirements for integrating an EPI SUSCEPTOR. Consider factors like size, material compatibility, and operational parameters. Determine if your existing equipment needs modifications to accommodate the susceptor. For instance, you might need to upgrade heating elements or adjust wafer handling systems.

It’s also important to plan for additional resources. This could include training for your team or acquiring new tools. Clearly outlining these requirements ensures a smoother integration process.

Ensuring Compliance with Industry Standards

Compliance with industry standards is critical when adding an EPI SUSCEPTOR to your production line. Research the relevant guidelines for semiconductor manufacturing. These standards often cover material specifications, safety protocols, and performance benchmarks. Make sure your susceptor and equipment meet these criteria.

You should also document your compliance efforts. This includes keeping records of inspections, certifications, and testing results. Following industry standards not only ensures safety but also enhances the reliability of your production line.

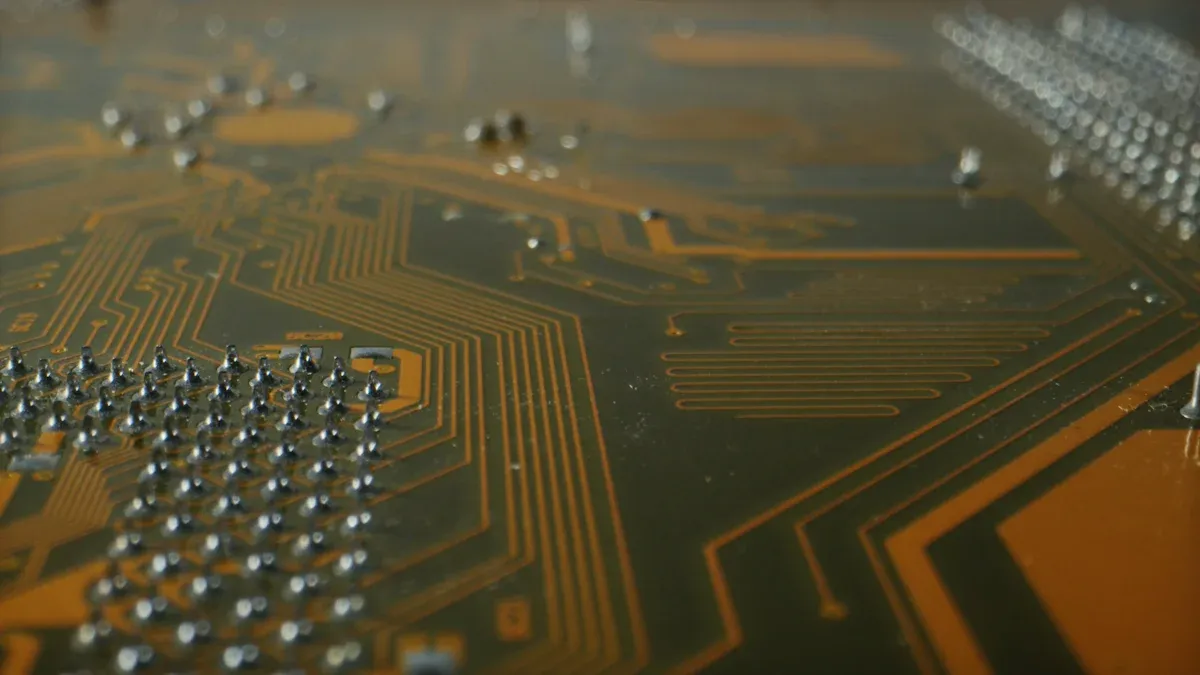

Equipment Compatibility

Assessing Compatibility with Existing Machinery

You need to evaluate whether your current machinery can support the integration of an EPI SUSCEPTOR. Start by reviewing the technical specifications of your equipment. Check for compatibility in terms of size, weight capacity, and thermal performance. For example, some machines may require adjustments to accommodate the susceptor’s unique design or material properties.

Create a checklist to identify potential conflicts. Include factors like heating element capacity, wafer handling systems, and software controls. If your equipment lacks the necessary features, you may need to consider upgrades or modifications. This step ensures that your production line operates efficiently after the integration.

Upgrading or Modifying Equipment for EPI Susceptors

When your existing machinery falls short, upgrading or modifying it becomes essential. Begin by consulting with equipment manufacturers or industry experts. They can recommend solutions tailored to your production line. Common upgrades include enhancing heating systems, improving alignment mechanisms, or adding advanced monitoring tools.

Modifications should focus on optimizing performance. For instance, you might need to adjust the chamber design to ensure uniform heat distribution. Always test the upgraded equipment before full-scale implementation. This minimizes downtime and ensures smooth operation.

Tip: Document all changes made to your machinery. This helps with troubleshooting and ensures compliance with industry standards.

Verifying Material and Design Specifications

The material and design of the EPI SUSCEPTOR must align with your production requirements. Verify that the susceptor’s material can withstand high temperatures and chemical exposure during the epitaxial growth process. Check its design for compatibility with your wafer sizes and handling systems.

Use technical drawings and specifications to confirm alignment. If discrepancies arise, consult with the susceptor manufacturer for adjustments. Proper verification prevents operational issues and ensures consistent product quality.

Installation Process

Step-by-Step Physical Installation of EPI Susceptors

Installing an EPI SUSCEPTOR requires careful planning and execution. Follow these steps to ensure a smooth installation:

- Prepare the Workspace: Clean the installation area thoroughly to remove dust and debris. Ensure the environment meets the required temperature and humidity levels for semiconductor equipment.

- Inspect the Susceptor: Check the EPI SUSCEPTOR for any physical damage or manufacturing defects. Verify its specifications against your production line requirements.

- Position the Susceptor: Place the susceptor in the designated area within the epitaxial reactor. Use alignment tools to ensure accurate placement.

- Secure the Susceptor: Fasten the susceptor using the recommended mounting hardware. Avoid over-tightening, as this can cause stress fractures.

- Connect Supporting Systems: Attach any necessary connections, such as thermal sensors or monitoring equipment. Confirm that all connections are secure and functional.

- Perform Initial Checks: Power on the equipment and monitor the susceptor’s performance. Look for signs of misalignment or irregularities in operation.

Tip: Keep a detailed log of the installation process. This documentation will help with troubleshooting and future maintenance.

Ensuring Proper Alignment and Placement

Proper alignment is critical for the performance of an EPI SUSCEPTOR. Misalignment can lead to uneven thermal distribution and compromised wafer quality. Use precision tools, such as laser alignment systems, to position the susceptor accurately.

Check the alignment from multiple angles to confirm uniformity. Pay close attention to the susceptor’s orientation relative to the heating elements and wafer handling systems. If adjustments are needed, make them incrementally to avoid disrupting other components.

Note: Regularly calibrate your alignment tools to maintain accuracy during installation.

Safety Protocols During Installation

Safety should be your top priority when installing an EPI SUSCEPTOR. Follow these protocols to protect your team and equipment:

- Wear Protective Gear: Equip yourself with gloves, goggles, and anti-static clothing to prevent contamination and injury.

- Follow Manufacturer Guidelines: Adhere to the installation instructions provided by the susceptor manufacturer. These guidelines often include specific torque settings and handling precautions.

- Monitor Electrical Systems: Ensure all electrical connections are powered off during installation. Use insulated tools to minimize the risk of electric shock.

- Handle with Care: Avoid dropping or mishandling the susceptor, as this can cause irreparable damage. Use lifting equipment for heavy or delicate components.

- Conduct Safety Checks: Inspect the installation area for hazards, such as loose wires or unstable surfaces. Address these issues before proceeding.

Alert: Never bypass safety protocols to save time. Shortcuts can lead to accidents and costly equipment damage.

Calibration and Testing

Calibrating Equipment for EPI Susceptor Performance

Calibration ensures your equipment operates optimally with the EPI SUSCEPTOR. Begin by reviewing the manufacturer’s calibration guidelines. These instructions often include specific temperature ranges and alignment settings. Use precision tools like thermocouples and laser alignment systems to measure and adjust the equipment.

Focus on the heating elements first. Verify that they distribute heat evenly across the susceptor’s surface. Uneven heating can lead to inconsistent wafer quality. Next, check the sensors and monitoring systems. Ensure they provide accurate readings during the epitaxial growth process.

Perform a trial run after calibration. Monitor the equipment closely to confirm that all adjustments are effective. If discrepancies arise, recalibrate immediately to avoid production delays.

Tip: Schedule regular calibration sessions to maintain consistent performance and prevent long-term issues.

Conducting Initial Testing and Quality Assurance

Testing validates the integration of the EPI SUSCEPTOR into your production line. Start by running a controlled batch of wafers through the system. Observe the susceptor’s performance under standard operating conditions.

Pay attention to key metrics like thermal uniformity, wafer alignment, and chemical stability. Use diagnostic tools to collect data during the test. Compare this data to your production benchmarks to identify any deviations.

Conduct visual inspections of the wafers after testing. Look for signs of defects, such as uneven surfaces or discoloration. These issues often indicate problems with the susceptor’s alignment or material compatibility.

Alert: Document all test results thoroughly. This information will help you refine the integration process and address future challenges.

Addressing Common Issues During Testing

Testing may reveal issues that need immediate attention. Misalignment is one of the most common problems. If the susceptor is not positioned correctly, it can cause uneven thermal distribution. Use alignment tools to make precise adjustments.

Material incompatibility is another frequent issue. Some susceptors may react poorly to the chemicals used in your production process. Consult the manufacturer to verify material specifications and consider alternative options if necessary.

Sensor inaccuracies can also disrupt testing. If monitoring systems provide incorrect readings, recalibrate them or replace faulty components.

Note: Addressing these issues promptly ensures a smoother transition and minimizes production downtime.

Maintenance and Troubleshooting

Establishing a Maintenance Schedule for EPI Susceptors

Regular maintenance keeps your EPI SUSCEPTOR functioning at its best. Start by creating a detailed schedule. Include tasks like cleaning, inspecting for wear, and checking alignment. Perform these tasks weekly or monthly, depending on your production volume.

Focus on cleaning the susceptor’s surface. Residue buildup can affect thermal performance. Use approved cleaning agents and follow the manufacturer’s guidelines. Inspect for cracks or discoloration during each cleaning session. These signs often indicate material fatigue.

Document all maintenance activities. Keep a log of dates, tasks, and findings. This record helps you track performance trends and identify recurring issues.

Identifying and Resolving Common Operational Issues

Operational issues can disrupt production. The most common problems include uneven heating, misalignment, and material degradation. Address these issues quickly to avoid downtime.

If you notice uneven heating, check the alignment of the susceptor. Misalignment often causes inconsistent thermal distribution. Use alignment tools to correct the position. For material degradation, inspect the susceptor for cracks or discoloration. Replace it if necessary.

Sensor errors can also occur. Verify that all monitoring systems are calibrated. Replace faulty sensors to ensure accurate readings.

Tip: Train your team to recognize early signs of these issues. Early detection reduces repair costs and prevents production delays.

Tips for Long-Term Optimization and Performance

To optimize performance, follow best practices. Always use high-quality materials and tools during maintenance. Avoid shortcuts that compromise safety or efficiency.

Monitor the susceptor’s performance regularly. Use diagnostic tools to track metrics like thermal uniformity and alignment. Compare these metrics to your production benchmarks.

Invest in staff training. A well-trained team can handle maintenance and troubleshooting more effectively. Encourage them to stay updated on industry advancements.

Note: Consistent care and monitoring extend the lifespan of your EPI SUSCEPTOR and improve overall production quality.

Integrating EPI Susceptors involves preparation, equipment compatibility checks, installation, calibration, and maintenance. Proper integration boosts efficiency and ensures high-quality semiconductor production.

Tip: Follow best practices like regular maintenance and staff training. These steps help you achieve long-term success and keep your production line running smoothly.

FAQ

What is the lifespan of an EPI Susceptor?

The lifespan depends on usage and maintenance. With proper care, an EPI Susceptor can last several years. Regular cleaning and inspections help extend its durability.

Can you reuse an EPI Susceptor after damage?

No, damaged susceptors should not be reused. Cracks or discoloration compromise performance and wafer quality. Always replace damaged components to maintain production standards.

How do you choose the right EPI Susceptor for your production line?

Consider factors like material compatibility, size, and thermal requirements. Consult your equipment manufacturer for recommendations tailored to your specific production needs.

Tip: Always verify the susceptor’s specifications with your production benchmarks before purchasing.