Choosing the right graphite susceptor is crucial for enhancing your epitaxial growth system’s performance. It directly impacts deposition quality and operational efficiency. You should focus on factors like material purity, thermal behavior, and durability. Prioritizing these aspects ensures your system operates reliably, delivering consistent results over time.

Key Takeaways

- Pick a graphite susceptor made of very pure material. This stops contamination and improves the quality of the layers.

- Talk to manufacturers or experts to choose the right susceptor. Their advice can help you avoid expensive errors.

- Check how long the susceptor will last and its upkeep needs. A strong one might cost more now but saves money later.

The Role of a Graphite Susceptor in Epitaxial Growth Systems

What is a Graphite Susceptor?

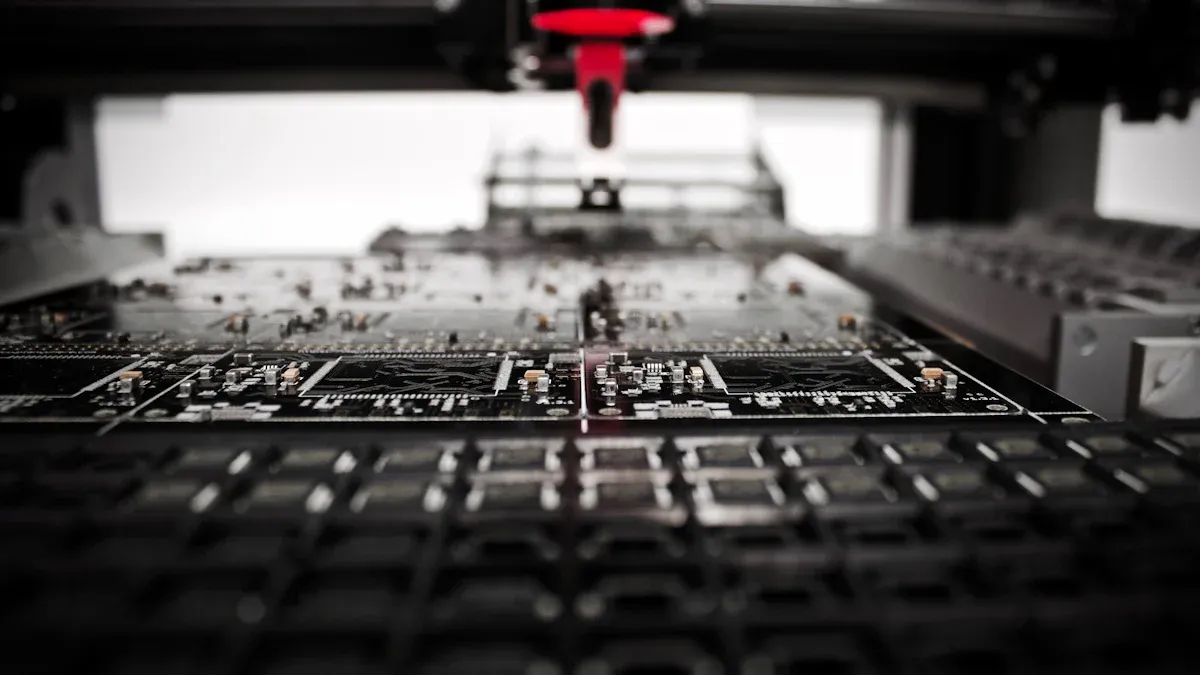

A graphite susceptor is a critical component in epitaxial growth systems. It is a specially designed structure made from high-purity graphite. Its primary role is to hold and support the substrate during the deposition process. The susceptor also absorbs heat from the system and distributes it evenly across the substrate. This ensures that the temperature remains consistent, which is essential for high-quality epitaxial layer growth.

Importance in Epitaxial Growth Processes

In epitaxial growth, precise temperature control is vital. The graphite susceptor plays a key role in maintaining this control. By evenly distributing heat, it prevents temperature fluctuations that could lead to defects in the deposited layers. Additionally, the susceptor’s material properties, such as thermal conductivity and chemical stability, make it ideal for withstanding the harsh conditions of epitaxial processes. Without a reliable susceptor, achieving uniform and defect-free layers becomes challenging.

Impact on Deposition Quality and System Efficiency

The quality of the graphite susceptor directly affects the deposition process. A well-designed susceptor ensures uniform heat distribution, which leads to consistent layer thickness and fewer defects. This improves the overall quality of the epitaxial layers. Furthermore, an efficient susceptor enhances the system’s energy usage by minimizing heat loss. This not only reduces operational costs but also extends the lifespan of the system components.

Key Factors to Consider When Selecting a Graphite Susceptor

Material Properties and Purity

When choosing a graphite susceptor, you should prioritize material properties and purity. High-purity graphite ensures minimal contamination during the epitaxial growth process. Impurities in the susceptor can transfer to the substrate, affecting the quality of the deposited layers. Look for graphite with low levels of metallic and non-metallic impurities. Additionally, consider the density and porosity of the material. A dense, low-porosity susceptor provides better thermal conductivity and durability.

Tip: Always request material specifications from the manufacturer to verify the purity and quality of the graphite.

System Compatibility and Design

Your epitaxial growth system has unique requirements, and the graphite susceptor must align with them. Check the susceptor’s size, shape, and design to ensure it fits seamlessly into your system. Some systems may require custom-designed susceptors to optimize performance. Also, consider the compatibility of the susceptor with your system’s operating temperature and gas environment. A mismatch can lead to inefficiencies or even damage to the system.

Note: Collaborating with the system manufacturer can help you identify the best susceptor design for your setup.

Thermal Performance and Heat Distribution

Thermal performance is a critical factor in epitaxial growth. The graphite susceptor must distribute heat evenly across the substrate to prevent temperature variations. Uneven heat distribution can cause defects in the epitaxial layers, reducing their quality. Evaluate the thermal conductivity of the graphite material. Higher conductivity ensures better heat transfer and uniformity. Additionally, consider the susceptor’s ability to withstand rapid temperature changes without cracking or deforming.

Tip: Testing the susceptor under actual operating conditions can help you assess its thermal performance.

Durability and Resistance to Corrosion

Graphite susceptors operate in harsh environments, often exposed to high temperatures and reactive gases. Durability and corrosion resistance are essential to ensure long-term performance. Choose a susceptor with a protective coating, such as silicon carbide (SiC), to enhance its resistance to chemical attack and wear. A durable susceptor reduces the frequency of replacements, saving you time and money.

Note: Regular maintenance and inspection can extend the lifespan of your susceptor.

Cost-Effectiveness and Long-Term Value

While initial cost is an important consideration, you should also evaluate the long-term value of the graphite susceptor. A cheaper susceptor may save money upfront but could lead to higher maintenance costs or reduced system efficiency. Invest in a high-quality susceptor that offers durability, consistent performance, and minimal downtime. This approach ensures better value over the lifespan of your epitaxial growth system.

Tip: Calculate the total cost of ownership, including maintenance and replacement costs, to make an informed decision.

Common Mistakes to Avoid

Focusing Solely on Initial Cost

Choosing a graphite susceptor based only on its price can lead to long-term issues. While a lower-cost option might seem appealing, it often sacrifices quality, durability, or performance. These compromises can result in higher maintenance expenses, frequent replacements, and reduced system efficiency.

Tip: Instead of focusing on the upfront cost, evaluate the total cost of ownership. Consider factors like lifespan, maintenance needs, and energy efficiency. A slightly higher initial investment can save you money over time.

You should also remember that cheaper susceptors may lack essential features, such as protective coatings or high-purity materials. These omissions can lead to contamination, defects in epitaxial layers, or even system damage. Always balance cost with quality to ensure reliable performance.

Neglecting System-Specific Requirements

Every epitaxial growth system has unique specifications. Ignoring these requirements when selecting a susceptor can cause compatibility issues. For example, a susceptor that doesn’t fit your system’s design or operating conditions may lead to uneven heat distribution or mechanical failures.

Note: Collaborate with your system manufacturer or an industry expert to identify the exact specifications your susceptor needs to meet. This includes size, shape, material, and thermal performance.

Failing to account for your system’s gas environment or temperature range can also create problems. A susceptor designed for one type of system may not perform well in another. Always ensure the susceptor aligns with your system’s operational parameters.

Overlooking Coating and Material Enhancements

Graphite susceptors often operate in harsh environments, exposing them to high temperatures and reactive gases. Without proper coatings or material enhancements, they can degrade quickly. This reduces their lifespan and increases the risk of contamination.

Protective coatings, such as silicon carbide (SiC), enhance the susceptor’s resistance to wear and chemical attack. Skipping this feature might save money initially, but it can lead to frequent replacements and compromised deposition quality.

Tip: Always inquire about available coating options when selecting a susceptor. Coatings not only improve durability but also enhance thermal performance and reduce maintenance needs.

Additionally, some manufacturers offer advanced material treatments to improve the susceptor’s thermal conductivity or reduce porosity. These enhancements can significantly boost performance. Ignoring these options might limit your system’s efficiency and output quality.

Tips for Making the Final Decision

Consult with Manufacturers or Industry Experts

When selecting a graphite susceptor, reaching out to manufacturers or industry experts can provide valuable insights. These professionals understand the technical details of susceptors and can guide you toward the best option for your system. They can also help you evaluate material properties, coatings, and design features that align with your specific requirements.

Tip: Prepare a list of questions before consulting experts. Ask about material purity, thermal performance, and compatibility with your system. This ensures you gather all the necessary information to make an informed decision.

Collaborating with experts also allows you to explore custom solutions. If your system has unique specifications, manufacturers can design a susceptor tailored to your needs. This approach ensures optimal performance and long-term reliability.

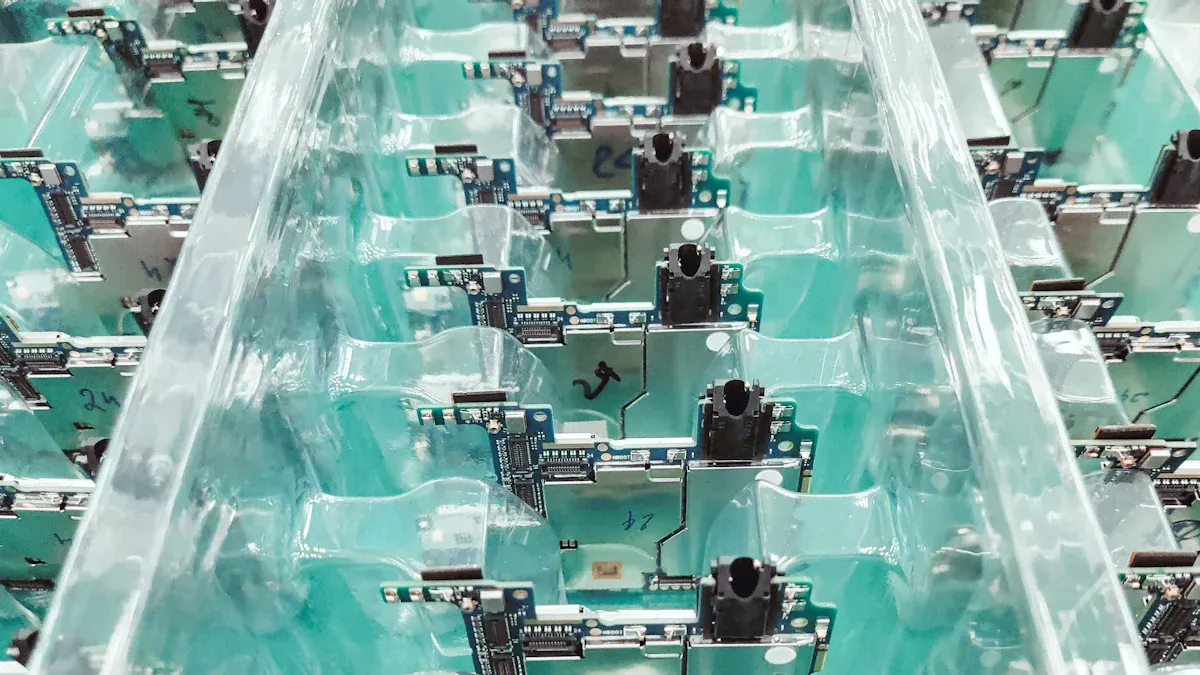

Test Prototypes for System Compatibility

Testing prototypes is a practical way to ensure the susceptor works seamlessly with your epitaxial growth system. A prototype allows you to evaluate how well the susceptor fits, performs, and withstands operating conditions.

During testing, focus on key factors like heat distribution, durability, and resistance to corrosion. Monitor the susceptor’s performance under real-world conditions to identify potential issues. Testing also helps you verify whether the susceptor meets your system’s temperature and gas environment requirements.

Note: Testing prototypes may involve additional time and cost, but it minimizes the risk of selecting an incompatible susceptor.

Evaluate Long-Term Performance and Maintenance Needs

Consider the long-term performance of the susceptor before making your final decision. A high-quality susceptor should deliver consistent results over its lifespan. Evaluate factors like durability, resistance to wear, and ease of maintenance.

Tip: Choose a susceptor with protective coatings, such as silicon carbide, to enhance its lifespan and reduce maintenance needs.

Think about the total cost of ownership. A durable susceptor may have a higher upfront cost but will save you money on replacements and repairs. Prioritizing long-term value ensures your epitaxial growth system operates efficiently for years to come.

Choosing the right graphite susceptor ensures your epitaxial growth system performs efficiently and produces high-quality results. Focus on material properties, system compatibility, and durability to make an informed decision. Avoid common mistakes and consult experts for guidance. By prioritizing these factors, you set your system up for long-term success.

FAQ

What is the lifespan of a graphite susceptor?

The lifespan depends on usage and maintenance. High-quality susceptors with protective coatings can last several years under optimal conditions.

How do you clean a graphite susceptor?

Use non-abrasive cleaning methods to avoid damage. Follow the manufacturer’s guidelines for cleaning agents and procedures to maintain performance.

Can you reuse a damaged susceptor?

Reusing a damaged susceptor is not recommended. Cracks or wear can lead to uneven heat distribution and contamination, affecting deposition quality.

Tip: Regular inspections help identify damage early, reducing the risk of system inefficiencies.