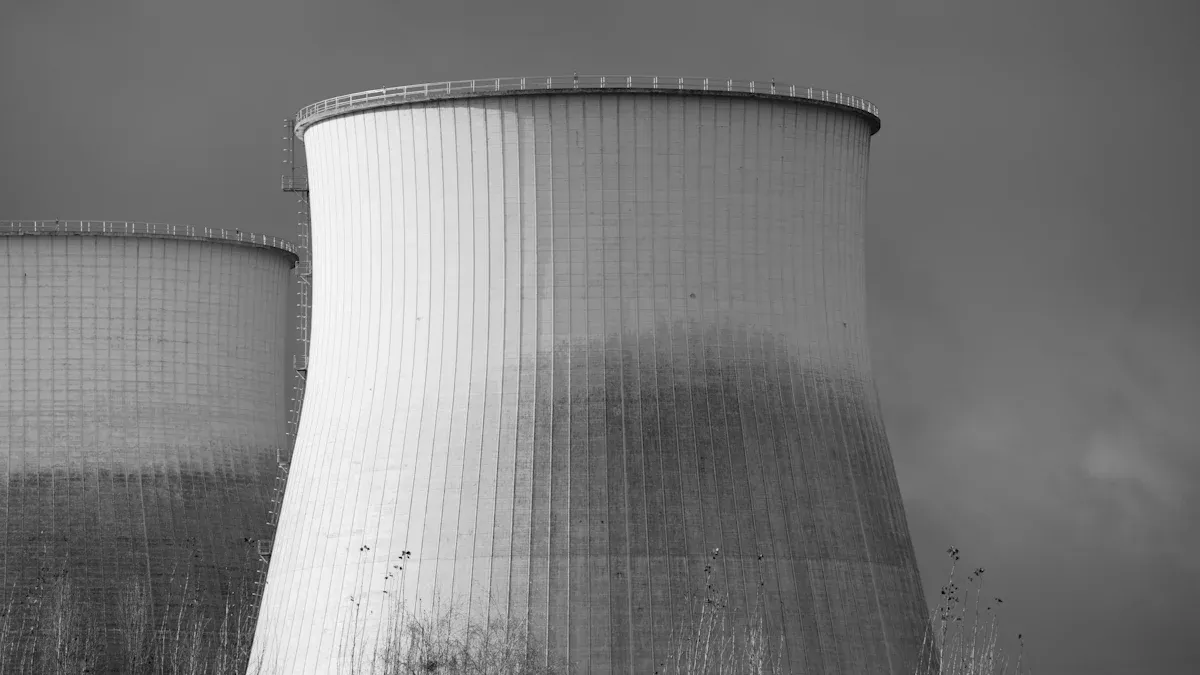

Nuclear reactor components face extreme conditions that demand durable solutions. TAC coating provides a robust barrier, protecting these components from wear, corrosion, and high temperatures. This innovation enhances reactor safety and efficiency while extending component life. Growing interest in nuclear energy has increased the need for advanced materials like TAC coating to meet industry demands.

Key Takeaways

- TAC coatings shield reactor parts from damage, rust, and heat. This improves safety and performance.

- New methods like PVD and CVD make coatings better. They also cut down on wasted materials.

- Tiny-layered coatings are very strong and resist chemicals well. They work great in tough reactor conditions.

Understanding TAC Coating Technology

Key Properties of TAC Coatings

TAC coatings exhibit exceptional properties that make them ideal for nuclear reactor components. These coatings provide outstanding resistance to oxidation and corrosion, even in extreme environments. Their ability to withstand high temperatures ensures stability during prolonged reactor operations. Additionally, TAC coatings possess excellent mechanical strength, which helps protect components from wear and tear caused by constant stress.

Another key feature is their low thermal conductivity. This property minimizes heat transfer, which is crucial for maintaining the structural integrity of reactor components. TAC coatings also demonstrate remarkable chemical resistance, allowing them to endure exposure to aggressive substances commonly found in nuclear reactors. These combined properties make TAC coatings a reliable choice for enhancing the performance and durability of critical systems.

Importance in Nuclear Applications

In nuclear reactors, components face harsh conditions that can compromise their functionality. TAC coatings play a vital role in addressing these challenges. By providing a robust barrier, they protect surfaces from oxidation and corrosion, which are common issues in high-temperature environments. This protection reduces the risk of component failure, ensuring the reactor operates safely and efficiently.

TAC coatings also contribute to the longevity of reactor components. Their ability to resist chemical degradation and thermal stress extends the lifespan of critical parts. This reduces the need for frequent maintenance and replacement, saving time and resources. Furthermore, the enhanced durability provided by TAC coatings improves overall reactor reliability, which is essential for meeting the growing demand for nuclear energy.

Challenges in Nuclear Reactor Components

Oxidation and Corrosion Resistance

Nuclear reactor components operate in environments where oxidation and corrosion are constant threats. High temperatures and exposure to oxygen-rich atmospheres accelerate these processes. Over time, oxidation weakens materials, making them brittle and prone to failure. Corrosion, on the other hand, degrades surfaces, reducing their structural integrity. These issues can lead to costly repairs and potential safety risks. TAC Coating provides a protective layer that shields components from these damaging effects, ensuring long-term reliability.

Thermal Stress and High-Temperature Stability

Reactor components endure extreme temperature fluctuations during operation. These changes cause thermal stress, which can lead to cracks and material deformation. High-temperature stability is essential to prevent such damage. Materials must maintain their strength and shape even under prolonged exposure to heat. Advanced coatings like TAC Coating help components withstand these conditions by enhancing their thermal resistance. This ensures that critical parts remain functional and safe throughout the reactor’s lifespan.

Chemical Resistance in Harsh Environments

Nuclear reactors expose components to aggressive chemicals, including radioactive substances and coolants. These chemicals can erode unprotected surfaces, compromising their performance. Chemical resistance is crucial for maintaining the integrity of reactor parts. Protective coatings act as a barrier, preventing chemical interactions that could weaken materials. By resisting chemical attacks, these coatings extend the life of components and reduce the need for frequent maintenance.

Innovations in TAC Coating Technology

Advanced Deposition Techniques

Advancements in deposition techniques have significantly improved the performance of TAC Coating. These methods ensure precise application, resulting in uniform layers that enhance durability and functionality. One of the most notable innovations is physical vapor deposition (PVD). This technique uses vaporized material to create thin, high-quality coatings. PVD ensures excellent adhesion and minimizes defects, making it ideal for nuclear reactor components.

Another breakthrough is chemical vapor deposition (CVD). This process involves chemical reactions to form coatings with exceptional density and purity. CVD provides superior coverage, even on complex geometries, ensuring every surface is protected. Additionally, plasma-enhanced deposition has gained attention for its ability to deposit coatings at lower temperatures. This method reduces thermal stress on components, preserving their structural integrity.

Tip: Advanced deposition techniques not only improve coating quality but also reduce material waste, making them environmentally friendly.

Nanostructured Coatings

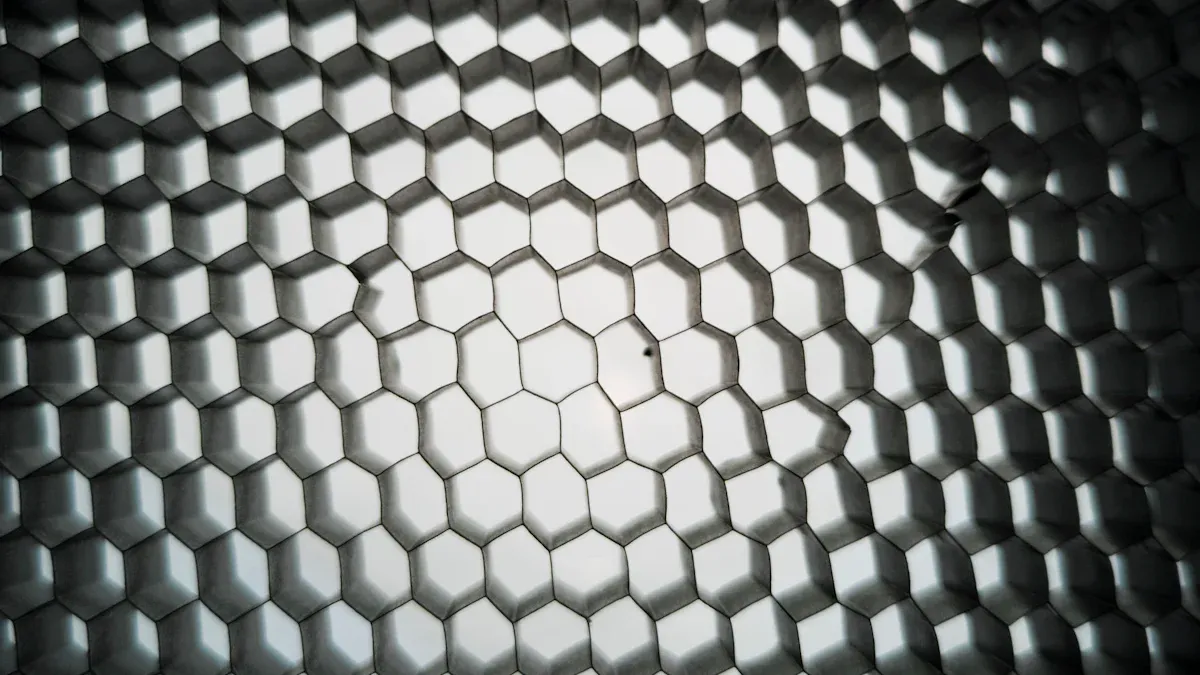

Nanostructured coatings represent a leap forward in TAC Coating technology. These coatings are engineered at the nanoscale, giving them unique properties that outperform traditional materials. Their fine structure enhances hardness and wear resistance, making them ideal for high-stress environments.

One key advantage of nanostructured coatings is their ability to resist cracking. The nanoscale grains distribute stress more evenly, preventing fractures. Additionally, these coatings exhibit improved thermal stability. They maintain their properties even under extreme temperatures, ensuring reliable performance in nuclear reactors.

Nanostructured coatings also offer superior chemical resistance. Their dense structure creates a barrier that prevents chemical penetration, protecting components from degradation. Researchers continue to explore new nanomaterials, such as graphene and carbon nanotubes, to further enhance these coatings’ capabilities.

Hybrid Coating Systems

Hybrid coating systems combine multiple materials to achieve enhanced performance. These systems integrate the strengths of different coatings, creating a solution tailored to specific challenges. For example, a hybrid system might pair a corrosion-resistant layer with a thermally stable one. This combination provides comprehensive protection against both chemical and thermal damage.

One innovative approach involves multi-layered coatings. Each layer serves a distinct purpose, such as resisting oxidation or improving adhesion. Together, they create a robust barrier that extends the lifespan of reactor components. Another strategy is the use of composite coatings, which blend materials like ceramics and metals. These coatings offer a balance of strength, flexibility, and resistance to wear.

Hybrid systems also allow for customization. Engineers can adjust the composition and thickness of each layer to meet the specific needs of a reactor. This flexibility ensures optimal performance, even in the most demanding conditions.

Applications of TAC Coatings in Nuclear Energy

Enhancing Component Longevity

Nuclear reactor components operate under extreme conditions, including high temperatures, radiation, and exposure to corrosive substances. These factors can degrade materials over time, leading to wear and failure. TAC coatings provide a protective barrier that significantly extends the lifespan of these components. By resisting oxidation, corrosion, and chemical attacks, these coatings preserve the structural integrity of critical parts.

The durability of TAC coatings reduces the frequency of component replacements. This not only lowers operational costs but also minimizes the environmental impact associated with manufacturing new parts. For example, turbine blades coated with TAC materials maintain their performance for longer periods, even under constant stress. This longevity ensures that reactors can operate efficiently without interruptions caused by component failures.

Note: Prolonging the life of reactor components also enhances the sustainability of nuclear energy, making it a more viable option for meeting global energy demands.

Improving Reactor Safety and Efficiency

Safety is a top priority in nuclear energy. Reactor components must perform reliably to prevent accidents and ensure smooth operations. TAC coatings enhance safety by protecting components from degradation that could compromise their functionality. For instance, these coatings prevent cracks and corrosion in pressure vessels, which are critical for containing radioactive materials.

Efficiency also improves with the use of TAC coatings. By reducing heat transfer through their low thermal conductivity, these coatings help maintain optimal operating temperatures. This ensures that reactors produce energy more effectively. Additionally, the enhanced chemical resistance of TAC coatings prevents contamination of reactor systems, further boosting efficiency.

Tip: Investing in advanced coatings like TAC not only improves safety but also increases the overall output of nuclear reactors, making them more competitive with other energy sources.

Reducing Maintenance and Downtime

Frequent maintenance and unexpected downtime can disrupt reactor operations and increase costs. TAC coatings address this issue by reducing the wear and tear on components. Their ability to withstand harsh conditions means that parts require less frequent inspections and repairs. This leads to more consistent reactor performance and fewer operational delays.

For example, fuel rods coated with TAC materials resist chemical degradation, allowing them to remain in service longer. This reduces the need for costly shutdowns to replace damaged rods. Similarly, heat exchangers with TAC coatings maintain their efficiency over time, minimizing the need for cleaning and maintenance.

Callout: Less downtime translates to higher energy output and lower costs, making nuclear power plants more economically viable.

Future Trends in TAC Coating Technology

Emerging Materials and Techniques

Researchers are exploring new materials to push the boundaries of TAC coating technology. Advanced ceramics, graphene, and carbon nanotubes are gaining attention for their exceptional properties. These materials offer improved hardness, thermal stability, and chemical resistance. Their integration into TAC coatings could lead to even greater performance in nuclear environments.

Innovative techniques are also transforming the way coatings are applied. Atomic layer deposition (ALD) is one such method. It allows for ultra-thin, highly uniform coatings with precise control over thickness. This precision ensures better adhesion and fewer defects. Another promising approach is laser-assisted deposition, which enhances coating density and durability by using high-energy lasers during application.

Note: Emerging materials and techniques aim to address the limitations of traditional coatings, paving the way for more efficient and reliable solutions.

Integration with Next-Generation Nuclear Reactors

Next-generation nuclear reactors demand materials that can withstand even harsher conditions. TAC coatings are evolving to meet these requirements. Small modular reactors (SMRs) and advanced fast reactors operate at higher temperatures and pressures. Coatings must adapt to these challenges while maintaining their protective properties.

Engineers are designing coatings specifically for these reactors. For example, multi-functional coatings can combine thermal insulation with radiation shielding. This integration reduces the need for additional materials, simplifying reactor designs. TAC coatings also play a role in improving the efficiency of molten salt reactors by protecting components from corrosive salts.

Potential to Revolutionize the Industry

TAC coatings hold the potential to transform the nuclear energy sector. Their ability to enhance safety, efficiency, and longevity makes them indispensable for modern reactors. By reducing maintenance needs and extending component life, these coatings lower operational costs. This makes nuclear energy more competitive with other power sources.

Callout: As TAC technology advances, it could enable the development of reactors that are safer, more efficient, and more sustainable. This innovation may redefine the future of clean energy.

TAC coatings play a critical role in protecting nuclear reactor components from extreme conditions. Innovations such as nanostructured and hybrid systems improve safety, efficiency, and durability. Researchers continue to explore emerging materials and techniques, paving the way for advanced reactors.

Note: TAC technology promises a safer, more sustainable future for nuclear energy.

FAQ

What does TAC stand for in TAC coatings?

TAC stands for Tantalum Aluminum Carbide. It is a ceramic material known for its exceptional resistance to heat, corrosion, and wear.

How do TAC coatings improve nuclear reactor safety?

TAC coatings protect components from oxidation, corrosion, and chemical degradation. This ensures structural integrity, reducing the risk of failures and enhancing reactor safety.

Are TAC coatings environmentally friendly?

Yes! Advanced deposition techniques minimize material waste, and the extended lifespan of coated components reduces the need for frequent replacements, lowering environmental impact. 🌱

Tip: TAC coatings not only improve performance but also contribute to sustainable energy solutions.