You must follow every step carefully when you replace a Graphite Rotor&Vane in a vacuum pump.

- Wear the right safety gear.

- Check the pump before starting.

- Remove old parts and clean the chamber.

Never skip inspections or rush the process. Your attention keeps your pump running safely.

Key Takeaways

- Always prepare with the right tools and safety gear, and check your vacuum pump thoroughly before starting to avoid problems.

- Remove old parts carefully, clean and inspect all surfaces, and install new vanes and rotors in the correct direction to ensure smooth pump operation.

- After reassembly, test the pump carefully and perform regular maintenance to keep your vacuum pump running strong and extend the life of its parts.

Graphite Rotor&Vane Replacement Preparation

Tools and Safety Equipment Needed

You need the right tools and safety gear before you start. Gather these items:

- Wrenches and screwdrivers that fit your pump

- Clean, lint-free cloths

- Replacement Graphite Rotor&Vane parts

- Vacuum pump oil (if needed)

- Safety gloves and goggles

- Dust mask

Tip: Always use tools in good condition. Worn tools can slip and cause injury.

Pre-Replacement Checks for Vacuum Pump

Check your vacuum pump before you begin. This step helps you spot problems early.

- Make sure the pump is off and unplugged.

- Let the pump cool down if it was running.

- Look for oil leaks or strange noises.

- Check the maintenance log for past issues.

- Confirm you have the correct Graphite Rotor&Vane for your model.

A careful check now can save you time later.

Safety Precautions Before Starting

You must protect yourself and your equipment. Follow these safety steps:

- Wear gloves, goggles, and a dust mask.

- Work in a clean, well-ventilated area.

- Keep flammable materials away from your workspace.

- Read the pump manual for special warnings.

- Make sure you have a fire extinguisher nearby.

Never skip safety steps. Your health and the pump’s life depend on it.

Disassembly for Graphite Rotor&Vane Access

Safe Shutdown and Pressure Relief

You must start by shutting down the vacuum pump safely. Turn off the power switch and unplug the pump from the outlet. Wait for the pump to cool if it has been running. Release any built-up pressure by opening the vent valve or following your pump’s manual. This step keeps you safe from sudden air bursts or hot surfaces.

Note: Never skip pressure relief. Sudden pressure release can cause injury or damage parts.

Removing External Covers and Components

Next, remove the external covers. Use the correct screwdriver or wrench for your pump. Place all screws and bolts in a small container so you do not lose them. Take off any hoses or fittings that block access to the pump chamber. If your pump has a fan cover or filter, remove these as well.

- Keep track of each part you remove.

- Take a photo before you start if you need help remembering the order.

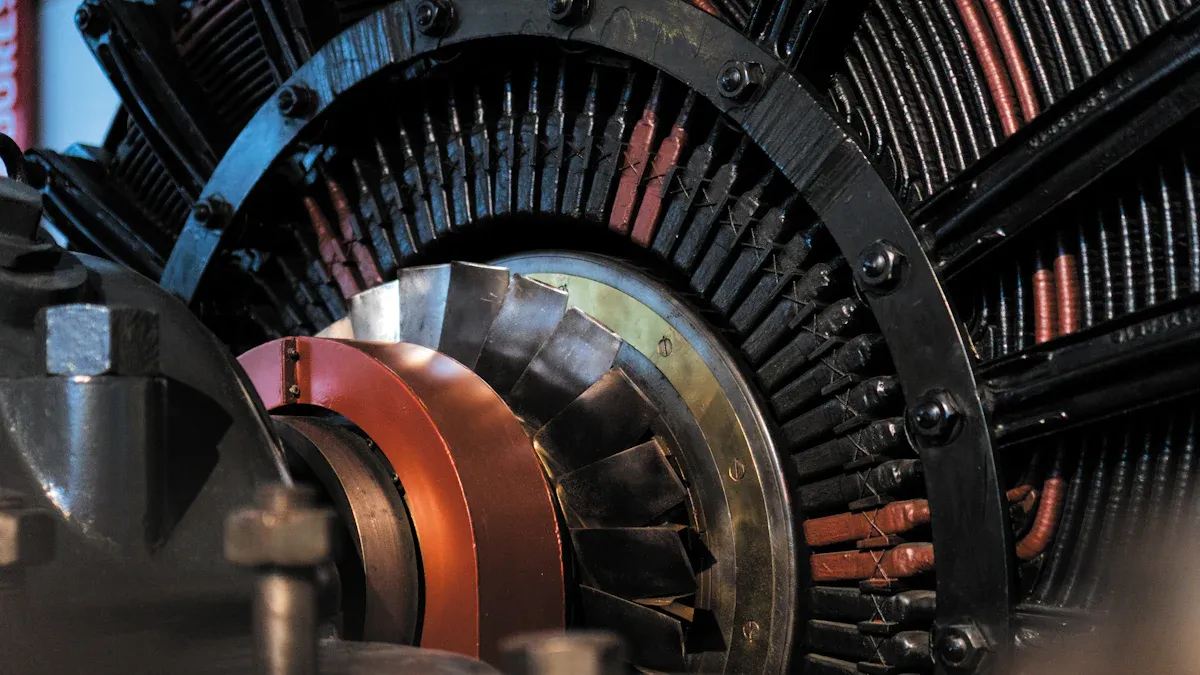

Opening the Pump Chamber

Now, open the pump chamber to reach the Graphite Rotor&Vane. Loosen the bolts around the chamber evenly. Lift the cover slowly and set it aside on a clean surface. Look inside for any signs of oil or debris. Make sure you do not damage the chamber seal.

Tip: Handle all parts with care. Scratches or dents can affect the pump’s performance.

Removing Old Graphite Rotor&Vane

Extracting Worn Graphite Vanes and Rotors

You need to remove the old vanes and rotors with care. Start by looking inside the pump chamber. You will see the vanes sitting in slots on the rotor. Use your fingers or a plastic tool to slide each vane out. Do not use metal tools because they can scratch the rotor or chamber walls.

If the vanes feel stuck, gently wiggle them back and forth. Sometimes, oil or dust makes them hard to move. Take your time. Pull each vane out straight so you do not chip the edges. After you remove the vanes, lift the rotor out of the chamber. Hold the rotor with both hands to keep it steady.

Tip: Place each part on a clean cloth. This keeps dirt away and helps you remember the order for reassembly.

Inspecting for Wear, Damage, or Debris

Now, you must check each part for problems. Look at the vanes first. Worn vanes may look thin or have rounded edges. Cracks or chips mean you need to replace them. Check the rotor for scratches, grooves, or broken corners. If you see black dust or small pieces, this means the Graphite Rotor&Vane has worn down.

Use a flashlight to look inside the pump chamber. Search for leftover debris or oil sludge. Clean out any loose material with a lint-free cloth. If you find deep scratches or dents in the chamber, you may need to repair or replace it.

| Part | What to Look For | Action Needed |

|---|---|---|

| Vanes | Cracks, chips, thinning | Replace if damaged |

| Rotor | Scratches, grooves | Replace if severe |

| Chamber | Debris, dents | Clean or repair |

Never ignore signs of damage. Even small cracks or dust can cause pump failure.

Cleaning and Inspection After Removal

Cleaning Pump Chamber and Rotor Slots

You need to clean the pump chamber and rotor slots before you install new parts. Start by wiping the inside of the chamber with a clean, lint-free cloth. Remove all dust, oil, and leftover debris. Use a soft brush to reach into the rotor slots. Make sure you do not leave any particles behind. If you see sticky oil or sludge, use a small amount of pump oil on your cloth to help clean it away.

- Use only non-abrasive tools and cloths.

- Avoid using water or harsh chemicals.

- Double-check that all surfaces are dry before moving on.

Tip: A clean chamber helps your new parts last longer and work better.

Checking for Broken Pieces and Surface Issues

After cleaning, you must inspect every surface. Look for broken pieces from the old vanes or rotor. Small fragments can hide in corners or slots. Use a flashlight to check hard-to-see areas. Run your finger gently along the chamber walls and rotor slots. You should feel a smooth surface. If you find scratches, dents, or rough spots, note them. These issues can cause early wear or pump failure.

| Area Checked | What to Look For | What to Do |

|---|---|---|

| Chamber Walls | Cracks, dents, debris | Clean or repair as needed |

| Rotor Slots | Chips, roughness | Smooth or replace |

| Corners/Edges | Hidden fragments | Remove all debris |

Never skip this inspection. Even a tiny piece left behind can damage your new parts.

Installing New Graphite Rotor&Vane

Correct Orientation and Chamfering Direction

You must install each new vane and rotor in the correct direction. Look at the vanes closely. One edge has a small angled cut. This is the chamfered edge. The chamfer helps the vane slide smoothly in the slot. Always face the chamfered edge in the direction the rotor spins. If you install the vanes backward, the pump will not work well.

Follow these steps to check the orientation:

- Hold the vane next to the rotor slot.

- Find the chamfered edge.

- Match the chamfered edge with the direction of rotation. The pump manual or an arrow on the rotor will show you which way it turns.

- Slide the vane into the slot gently.

Tip: If you feel unsure, check the old vanes before you throw them away. They show you the correct direction.

A table can help you remember what to check:

| Step | What to Look For | Why It Matters |

|---|---|---|

| Find chamfered edge | Angled or sloped corner | Reduces wear and friction |

| Check rotation | Arrow or manual direction | Ensures proper operation |

| Insert vane | Chamfer faces rotation | Prevents early failure |

Ensuring Free Movement and Proper Fit

You need to make sure each vane moves freely in its slot. If a vane sticks, the pump will not create a good vacuum. After you insert each vane, push it back and forth with your finger. The vane should slide in and out without force. If you feel resistance, remove the vane and check for dirt or burrs. Clean the slot again if needed.

Check the fit of the rotor as well. The rotor should sit flat in the chamber. Spin the rotor by hand. It should turn smoothly. If you hear scraping or feel tight spots, stop and inspect the parts. Sometimes, a small piece of debris or a misaligned vane causes problems.

Here is a checklist to help you:

- Slide each vane in and out of its slot.

- Spin the rotor by hand to check for smooth movement.

- Listen for unusual sounds.

- Remove and clean any part that feels tight or rough.

Never force a part into place. Forcing can break the new Graphite Rotor&Vane and damage the pump.

When you finish this step, you set up your pump for a long and reliable life.

Reassembly and Testing of Vacuum Pump

Aligning and Securing All Components

You need to place each part back in its correct position. Start by setting the rotor inside the pump chamber. Make sure the rotor sits flat and lines up with the chamber walls. Insert the vanes into their slots. Check that each vane moves freely. Place the chamber cover on top and match the bolt holes. Tighten the bolts in a crisscross pattern. This helps the cover seal evenly. Use your hands to tighten first, then finish with a wrench. Do not over-tighten, or you might damage the seal.

Tip: Take your time during this step. Careful alignment prevents leaks and keeps your pump running well.

Manual Rotor Spin and Initial Checks

Before you power up the pump, spin the rotor by hand. The rotor should turn smoothly without sticking. Listen for any scraping sounds. If you hear noise or feel resistance, stop and check the parts again. Look for dirt or a misaligned vane. Fix any problems before moving forward.

Here is a quick checklist:

- Spin the rotor by hand

- Listen for unusual sounds

- Check for smooth movement

- Inspect for loose bolts

Operational Testing for Performance

Plug in the vacuum pump and turn it on. Watch the pump as it starts. Check for leaks around the chamber cover. Listen for steady, quiet operation. Monitor the vacuum gauge. The pump should reach its normal vacuum level. If you see oil leaks or hear loud noises, turn off the pump and inspect your work.

Note: Always stay near the pump during the first test. Quick action can prevent damage if something goes wrong.

Final Checks and Maintenance for Graphite Rotor&Vane

Critical Final Inspections

You need to check your work before you call the job finished. Look at every bolt and make sure each one is tight. Check the chamber cover for a good seal. Watch for any oil leaks around the pump. Spin the rotor by hand one more time. Listen for any strange sounds. If you hear grinding or scraping, stop and open the pump again.

Use this checklist to help you:

- All bolts tightened in a crisscross pattern

- Chamber cover sealed with no gaps

- No oil leaks present

- Rotor spins smoothly and quietly

- Vanes move freely in their slots

Always double-check your work. A careful inspection now can prevent big problems later.

Ongoing Maintenance Tips for Longevity

You want your vacuum pump to last a long time. Regular care helps you avoid breakdowns. Change the oil as the manual suggests. Keep the pump clean and dry. Check the Graphite Rotor&Vane for wear every few months. Replace them if you see chips or cracks. Write down each maintenance step in a logbook. This record helps you spot patterns and plan future care.

Here is a simple table for your maintenance schedule:

| Task | How Often |

|---|---|

| Oil change | Every 3 months |

| Clean pump exterior | Monthly |

| Inspect vanes & rotor | Every 6 months |

| Check for leaks | Monthly |

Good maintenance keeps your pump strong and your work safe.

You can achieve a successful Graphite Rotor&Vane change by following each step carefully.

- Inspect every part.

- Clean all surfaces.

- Test the pump after reassembly.

Regular maintenance keeps your vacuum pump strong and extends the life of the Graphite Rotor&Vane.

FAQ

How often should you replace the Graphite Rotor&Vane?

You should check the vanes every six months. Replace them if you see chips, cracks, or thinning.

Regular checks help prevent pump failure.

What signs show the vanes or rotor need changing?

Look for these signs:

- Strange noises

- Lower vacuum pressure

- Visible wear or dust inside the pump

Can you reuse old vanes or rotors?

No, you should never reuse old vanes or rotors.

Worn parts can damage your pump and reduce its life.