An EPI SUSCEPTOR holds and aligns semiconductor wafers during epitaxial growth. This component helps wafers receive even heat. The EPI SUSCEPTOR’s design, material, and condition control the quality of the layers formed on the wafer. Manufacturers depend on these factors to produce reliable semiconductor devices.

Key Takeaways

- EPI SUSCEPTORS hold wafers steady and spread heat evenly to ensure smooth, high-quality layers during semiconductor manufacturing.

- Choosing materials with good thermal stability and chemical resistance helps EPI SUSCEPTORS maintain shape and prevent contamination for better device performance.

- Regular cleaning and inspection of EPI SUSCEPTORS prevent defects, extend their life, and improve the yield and quality of semiconductor devices.

EPI SUSCEPTOR in Epitaxial Growth Processes

Wafer Support and Alignment

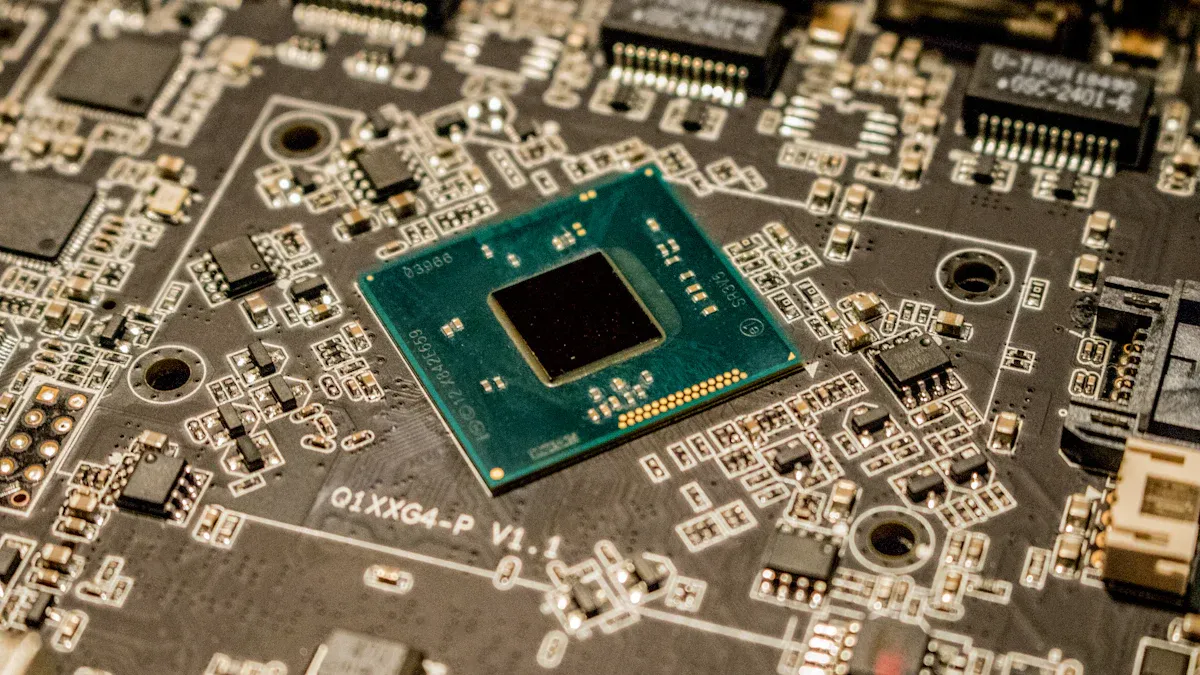

The EPI SUSCEPTOR holds the wafer in place during the epitaxial growth process. This support keeps the wafer flat and steady. When the wafer stays in the correct position, the machine can add new layers evenly. If the wafer moves or tilts, the layers may not form correctly. Many manufacturers use special grooves or pins on the EPI SUSCEPTOR to help with alignment. These features make sure each wafer sits in the same spot every time.

Tip: Good alignment helps prevent defects in the final semiconductor device.

Uniform Thermal Distribution

The EPI SUSCEPTOR spreads heat across the wafer surface. This even heating is important because the temperature affects how new layers grow. If some parts of the wafer get hotter than others, the layers may become uneven. The EPI SUSCEPTOR often uses materials that conduct heat well, such as graphite or coated ceramics. These materials help keep the temperature steady from the center to the edge of the wafer.

- Uniform heating leads to:

- Consistent layer thickness

- Fewer defects

- Better device performance

Influence on Epitaxial Layer Quality

The EPI SUSCEPTOR plays a big role in the quality of the epitaxial layer. When the wafer sits flat and receives even heat, the new layer grows smoothly. A clean and well-maintained EPI SUSCEPTOR also prevents contamination. Any particles or damage on the susceptor can cause problems in the layer. High-quality layers help make reliable and fast semiconductor devices.

Note: Regular cleaning and inspection of the EPI SUSCEPTOR can improve the yield and quality of semiconductor products.

EPI SUSCEPTOR Requirements and Performance Factors

Material Composition and Thermal Stability

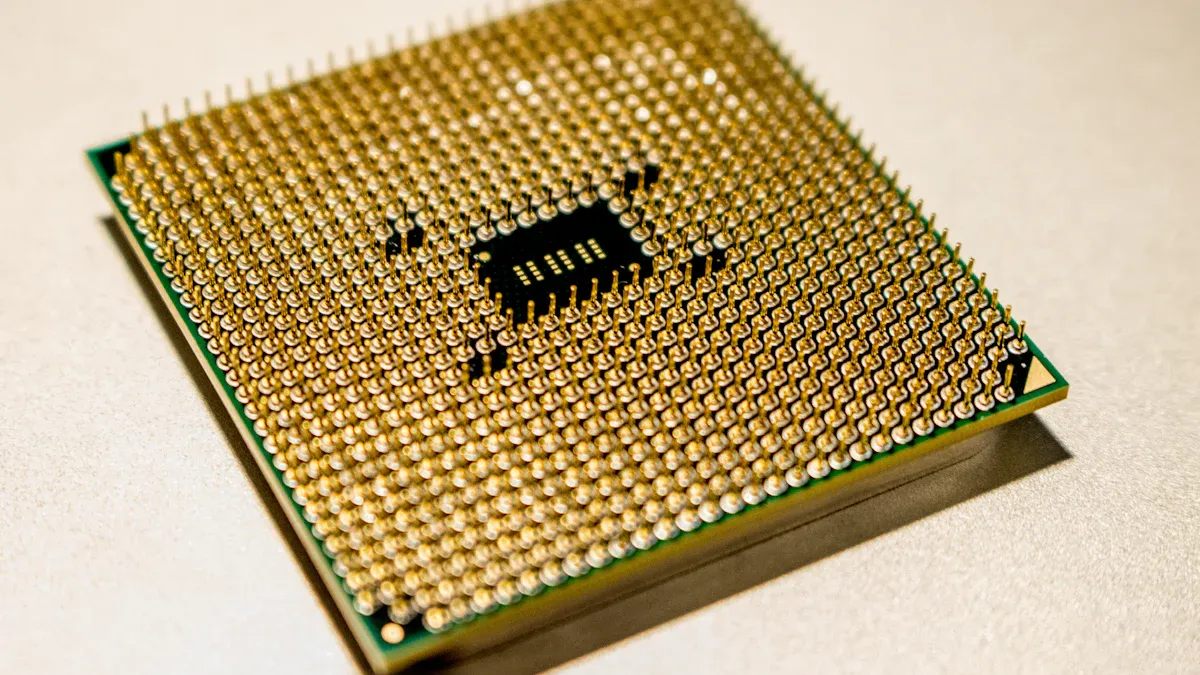

Engineers select materials for EPI SUSCEPTORs that can handle high temperatures. Graphite and coated ceramics often serve this purpose. These materials keep their shape and strength even when heated to extreme levels. Good thermal stability helps the susceptor deliver steady heat to the wafer. This property also prevents warping or cracking during repeated use.

Chemical Resistance and Contamination Control

The EPI SUSCEPTOR must resist chemicals used in the epitaxial process. Some gases and liquids can react with the susceptor surface. If this happens, unwanted particles may form. These particles can land on the wafer and cause defects. Manufacturers choose materials that do not react easily. They also clean the susceptor often to keep it free from contamination.

Note: Clean and chemically resistant susceptors help protect the wafer from damage.

Advanced Coatings and Surface Treatments

Many EPI SUSCEPTORs receive special coatings. These coatings improve resistance to chemicals and heat. Some coatings also make the surface smoother. A smooth surface helps prevent particles from sticking. Surface treatments can extend the life of the susceptor and improve wafer quality.

| Coating Type | Benefit |

|---|---|

| Silicon Carbide | High thermal stability |

| Quartz | Chemical resistance |

| Graphite Coating | Smooth surface |

Addressing Corrosion, Wear, and Particle Generation

Corrosion and wear can shorten the life of an EPI SUSCEPTOR. Over time, the surface may break down or release particles. These particles can lower the yield of good wafers. Regular inspection and maintenance help spot problems early. Replacing worn susceptors keeps the process reliable.

EPI SUSCEPTORs help manufacturers reach high precision and uniformity in semiconductor devices. Careful selection of materials and regular maintenance improve device quality. Investing in advanced EPI SUSCEPTOR technology supports better performance and higher yields.

Tip: Regular checks keep the process reliable.

FAQ

What is the main job of an EPI SUSCEPTOR?

The EPI SUSCEPTOR holds the wafer steady and spreads heat evenly. This helps create smooth, high-quality layers during semiconductor manufacturing.

How often should manufacturers clean EPI SUSCEPTORs?

Manufacturers should clean EPI SUSCEPTORs after each production cycle. Regular cleaning prevents contamination and keeps wafer quality high.

Can a damaged EPI SUSCEPTOR affect device performance?

Yes. A damaged EPI SUSCEPTOR may cause uneven heating or release particles. These issues can lower the quality and yield of semiconductor devices.

Tip: Regular inspection helps catch damage early and protects device quality.