When you choose a Graphite Ring for your equipment, focus on what your machine needs. Always match the Graphite Ring to your operating conditions. Think about the material, design, and how easy it is to install. These choices help your equipment last longer and work better.

Key Takeaways

- Match the graphite ring to your equipment’s temperature, pressure, and media to ensure a long-lasting, leak-free seal.

- Choose the right ring material and type based on your machine’s needs, such as flexibility, strength, and chemical resistance.

- Measure carefully and consider installation ease to get the best fit and reduce downtime during replacement.

Identify Your Equipment’s Operating Conditions for Graphite Ring Selection

Before you pick a Graphite Ring, you need to know how your equipment works every day. This step helps you avoid problems later. Let’s break down what you should look at.

Temperature and Pressure Requirements

Think about how hot or cold your equipment gets. Some machines run at very high temperatures, while others stay cool. Pressure matters too. High pressure can push hard on the Graphite Ring and cause it to wear out faster. If you know the temperature and pressure, you can choose a ring that will last longer and keep your machine safe.

Tip: Write down the highest and lowest temperatures and pressures your equipment faces. This list will help you talk to suppliers and find the right fit.

Type of Media (Liquids, Gases, Chemicals)

Ask yourself, “What flows through my equipment?” It could be water, oil, steam, or even harsh chemicals. Each type of media can affect the Graphite Ring in a different way. Some rings work well with water but not with strong acids. Others can handle gas but not thick liquids.

- If you use chemicals, look for rings that resist corrosion.

- For steam or hot gases, pick a ring that can handle heat.

- With thick liquids, make sure the ring will not break down or swell.

Knowing the media helps you avoid leaks and damage.

Static vs. Dynamic Applications

Does your equipment move, or does it stay still? This question matters a lot. Static applications mean the parts do not move much. Dynamic applications have moving parts, like pumps or rotating shafts. A Graphite Ring for a moving part needs to handle friction and wear. If your equipment stays still, you can focus more on sealing and less on wear.

Note: Always tell your supplier if your equipment moves or stays still. This detail changes the type of ring you need.

Evaluate Graphite Ring Material Properties

When you pick a Graphite Ring, you want to look at what it’s made of. The right material can make your equipment last longer and work better. Let’s break down the main things you should check.

Purity and Density

Purity tells you how much real graphite is in the ring. High purity means fewer fillers or extra stuff. If you use your equipment in tough places, you want a ring with high purity. Density is about how tightly packed the material is. Rings with higher density can handle more pressure and last longer.

Tip: Ask your supplier for the purity and density numbers. You can compare these to see which ring fits your needs best.

Chemical Resistance

Some machines deal with strong chemicals. You need a ring that won’t break down or react. If you use acids, bases, or other harsh liquids, check if the ring can resist them. Not all graphite rings are the same. Some have special coatings or mixes to help them fight off damage from chemicals.

- Make a list of the chemicals your equipment uses.

- Check if the ring can handle each one.

Thermal Conductivity and Expansion

Heat moves through graphite in a special way. Good thermal conductivity helps spread heat out, so your equipment stays safe. Expansion is about how much the ring grows when it gets hot. If the ring expands too much, it might not seal well. You want a ring that can handle the heat but won’t change shape too much.

| Property | Why It Matters |

|---|---|

| Thermal Conductivity | Keeps equipment cool |

| Expansion | Maintains a tight seal |

Select the Appropriate Graphite Ring Type

Choosing the right type of graphite ring can make a big difference in how your equipment works. Each type has its own strengths. Let’s look at the main options you’ll find.

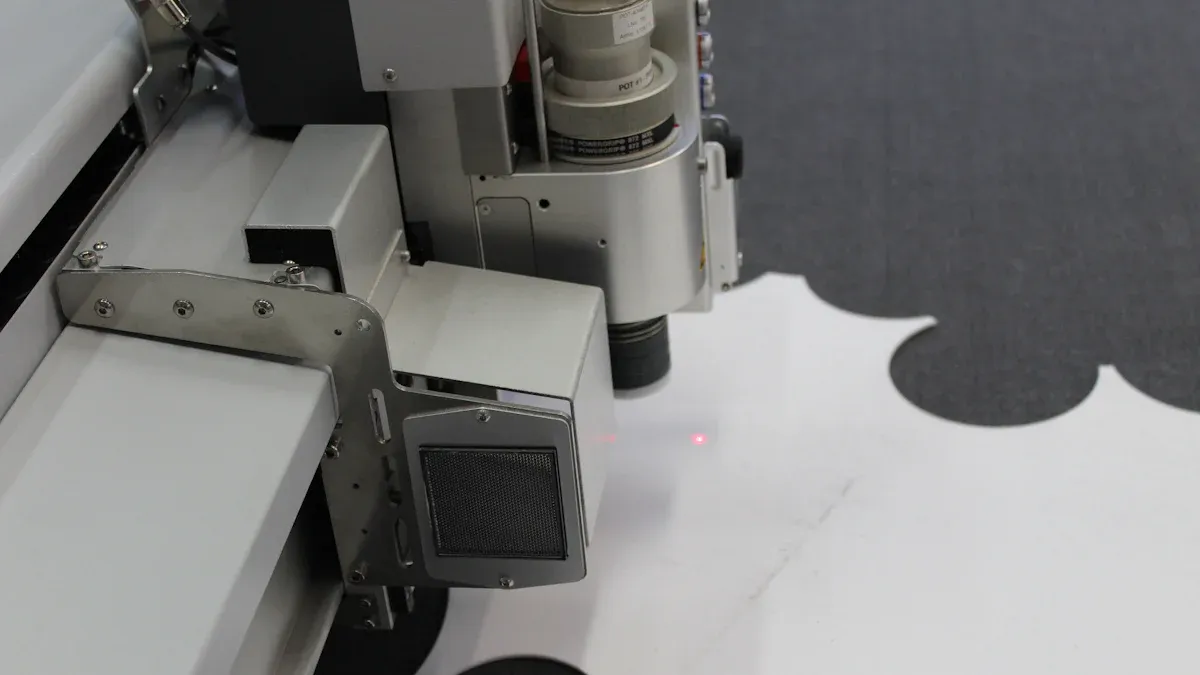

Flexible Graphite Rings

You might want a flexible graphite ring if you need a seal that can handle changes in pressure or temperature. These rings bend and adjust to fit tight spaces. They work well in pumps, valves, and other spots where things move or shift. You can install them easily, and they seal even if the surface isn’t perfect.

Tip: Flexible rings are great for quick fixes or when you need to replace seals often.

Molded Graphite Rings

Molded rings keep their shape under stress. If you need a strong, steady seal, this type works well. You’ll see them in high-pressure or high-temperature jobs. Molded rings last longer because they don’t wear out as fast.

Metal-Impregnated Graphite Rings

These rings have metal mixed in. The metal gives extra strength and helps the ring handle tough jobs. If your equipment faces a lot of wear or needs to resist crushing, try this type.

Resin-Impregnated Graphite Rings

Resin makes these rings less likely to leak. You get a tighter seal, which helps if you work with gases or thin liquids. Resin also helps the ring last longer in harsh chemicals.

Carbon-Graphite Composite Rings

This type mixes graphite with carbon. You get a ring that stands up to friction and heat. If your equipment runs fast or gets hot, this ring can help prevent damage.

Consider Graphite Ring Design Features

When you choose a Graphite Ring, you need to look at the design features. These details help you get the best fit and longest life for your equipment.

Dimensions and Tolerances

You want your ring to fit just right. If the ring is too big or too small, it can cause leaks or wear out fast. Always check the exact size you need. Look at the width, thickness, and inner diameter. Tolerances tell you how much the size can change and still work. Even a small difference can matter a lot.

Tip: Measure your equipment carefully before you order. Double-check the numbers with your supplier.

Split Rings vs. Solid Rings

You can pick between split rings and solid rings. Split rings come in two or more pieces. You can install them without taking apart your machine. They work well if you need to replace rings often. Solid rings come in one piece. They give a stronger seal but can be harder to install.

| Type | Easy to Install | Strong Seal | Good for Quick Fixes |

|---|---|---|---|

| Split Ring | ✅ | ❌ | ✅ |

| Solid Ring | ❌ | ✅ | ❌ |

Reinforcements and Coatings

Some rings have extra layers or coatings. These features help the ring last longer. Reinforcements can make the ring stronger. Coatings can protect against chemicals or heat. If your equipment faces tough jobs, ask about these options.

Note: Not every job needs reinforcements or coatings. Think about your equipment’s needs before you decide.

Confirm Fit and Installation Requirements for Graphite Ring

Bore Size and Clearances

You want your graphite ring to fit just right. If the bore size is off, you might see leaks or extra wear. Always measure the bore carefully before you order. Use a caliper or a micrometer for the best results. Check the manufacturer’s guide for the right clearances. Too much space can cause the ring to move around. Too little space can make installation tough.

Tip: Write down your measurements and double-check them before you buy. This step saves time and money.

Compatibility with Housing and Equipment

Your graphite ring needs to match your equipment’s housing. Look at the shape and material of the housing. Some housings need a special ring shape or extra support. If your equipment uses high pressure or heat, make sure the ring can handle it. Ask your supplier if you are not sure about the match.

Here’s a quick checklist:

- Check the housing material.

- Look for special shapes or grooves.

- Ask about pressure and temperature limits.

Ease of Installation and Replacement

You want a ring that is easy to install and replace. Split rings help you swap out old rings without taking apart the whole machine. Solid rings give a strong seal, but they might need more work to install. Think about how often you need to replace the ring. If you change rings often, pick a style that saves you time.

Remember: Easy installation means less downtime for your equipment.

Consult with Suppliers or Experts about Graphite Ring Selection

When you pick a Graphite Ring, you don’t have to do it alone. Suppliers and experts can help you make the best choice for your equipment. They know the details and can answer your questions. Let’s look at how you can get the most out of these conversations.

Request Technical Data and Certifications

Always ask for technical data before you buy. This information tells you how the ring will perform in your equipment. You can check things like temperature limits, pressure ratings, and chemical resistance. If you see a certification, you know the product meets certain standards. Certifications can give you peace of mind, especially if your equipment runs in tough conditions.

Tip: Make a checklist of what you need. Ask the supplier to match each point with data or a certificate.

Here’s a quick list of what to request:

- Material composition

- Operating temperature range

- Pressure limits

- Chemical compatibility

- Certifications (like ISO or ASTM)

Discuss Application Needs and Custom Solutions

Every machine is different. You might need a special size or shape. Don’t be afraid to talk about your exact needs. Suppliers can often make custom rings or suggest better options. Tell them about your equipment, the media you use, and how often you replace parts. The more details you share, the better advice you’ll get.

Remember: Good communication leads to better results. You save time and avoid costly mistakes.

You want your equipment to run smoothly, so remember these tips when picking a Graphite Ring. Match the ring to your machine’s needs and working conditions. If you feel unsure, reach out to a supplier or expert. They can help you make the best choice for your setup.

FAQ

What is the main benefit of using a graphite ring?

You get a strong seal that handles heat and pressure. Graphite rings also resist chemicals. Your equipment runs longer with fewer leaks.

How do I know if my graphite ring needs replacing?

Look for leaks, cracks, or worn edges. If you see any of these, it’s time to swap out the ring.

Can I install a graphite ring by myself?

Yes, you can. Just follow the manufacturer’s guide. Use the right tools and check your measurements before you start.