Silicon carbide offers high thermal stability and strong mechanical properties. Many industries trust SiC Cantilever Paddle solutions for reliable performance in harsh conditions. This material resists corrosion and handles extreme temperatures. Engineers select it when other materials fail to perform. Its unique characteristics help extend equipment life.

Key Takeaways

- Silicon carbide cantilever paddles offer unmatched strength, heat resistance, and chemical protection, making them ideal for harsh industrial environments.

- New manufacturing techniques in 2025 improve paddle durability and customization, helping industries get better performance and longer equipment life.

- Choosing silicon carbide paddles reduces maintenance costs and downtime, supporting safer and more efficient operations in demanding fields like semiconductors and solar energy.

SiC Cantilever Paddle: Key Advantages

Thermal Stability and High-Temperature Performance

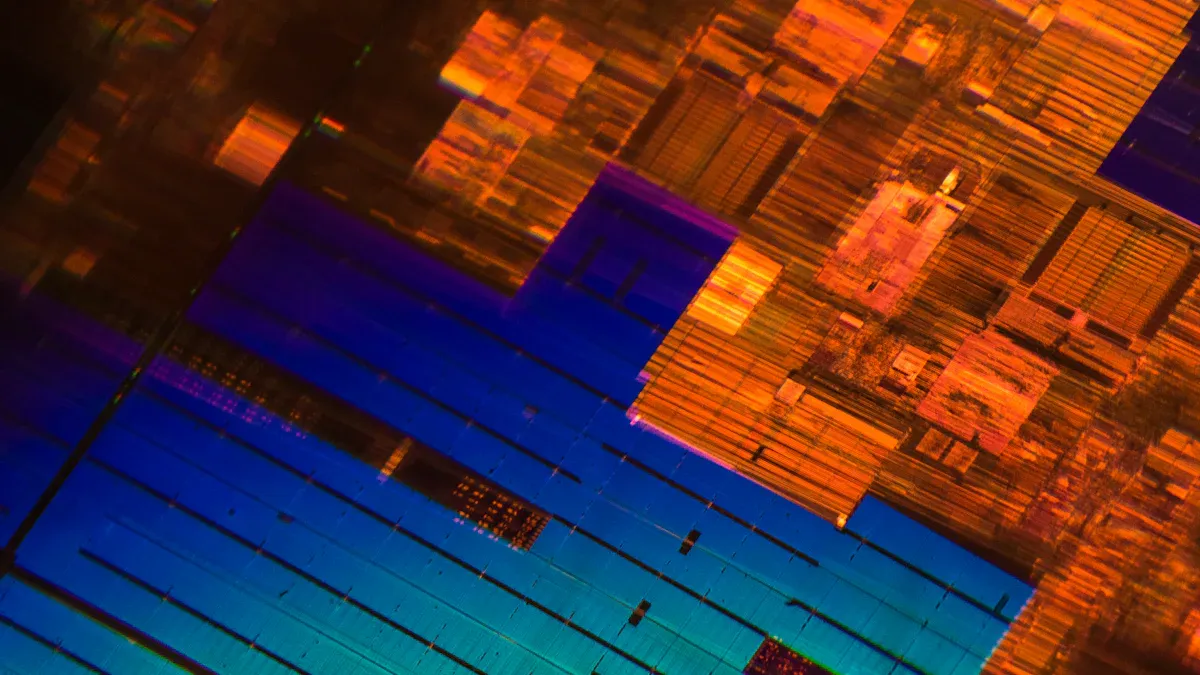

SiC Cantilever Paddle stands out for its ability to handle very high temperatures. Many industrial processes reach temperatures above 1,400°C. Most materials weaken or break down at these levels. Silicon carbide keeps its shape and strength. This property makes it a top choice for furnaces and reactors.

Engineers trust silicon carbide because it does not melt or deform easily. This stability helps protect equipment and ensures safe operation.

Mechanical Strength and Flexural Resistance

Silicon carbide has a strong atomic structure. This structure gives it high mechanical strength. SiC Cantilever Paddle can support heavy loads without bending or breaking. It resists cracks and chips, even under stress.

- High flexural strength means the paddle can handle repeated use.

- The material does not wear down quickly.

- It keeps its shape, which helps with precise movement in machines.

Chemical Resistance and Corrosion Protection

Many chemicals can damage metals and other ceramics. Silicon carbide resists acids, alkalis, and other harsh chemicals. This resistance protects the SiC Cantilever Paddle from corrosion.

| Material | Acid Resistance | Alkali Resistance | Corrosion Rate |

|---|---|---|---|

| Silicon Carbide | Excellent | Excellent | Very Low |

| Alumina | Good | Fair | Moderate |

| Quartz | Poor | Poor | High |

This table shows that silicon carbide offers the best protection in tough chemical environments.

Thermal Shock Resistance and Low Expansion

Rapid temperature changes can cause many materials to crack. Silicon carbide handles these changes well. It has a low thermal expansion rate. This means it does not expand or shrink much when heated or cooled.

- The paddle stays stable during quick heating and cooling cycles.

- This property reduces the risk of failure in demanding processes.

Note: Low thermal expansion helps maintain tight tolerances in high-precision applications.

SiC Cantilever Paddle vs. Alternative Materials

Silicon and Quartz Comparisons

Silicon and quartz often appear in high-temperature applications. Both materials offer some heat resistance. However, silicon can become brittle at high temperatures. Quartz may crack when exposed to rapid temperature changes. SiC Cantilever Paddle stays strong and stable in these situations. Many engineers choose silicon carbide because it does not break or deform easily. This choice helps reduce equipment failures.

Alumina and Other Ceramics

Alumina is another common ceramic. It provides good strength and resists some chemicals. Still, alumina does not match the toughness of silicon carbide. Other ceramics may offer low cost, but they often lack the durability needed for harsh environments. SiC Cantilever Paddle stands out because it handles both mechanical stress and chemical exposure better than most alternatives.

Cost, Performance, and Longevity

Some materials may cost less at first. Over time, frequent replacements and repairs increase total expenses. Silicon carbide lasts longer and needs less maintenance. This long life makes it a smart investment. Many industries see better performance and fewer breakdowns with SiC Cantilever Paddle. Choosing the right material saves money and keeps operations running smoothly.

Tip: Investing in quality materials like silicon carbide can lower long-term costs and improve safety.

Industry Trends and Advancements in 2025

Manufacturing Innovations for SiC Cantilever Paddle

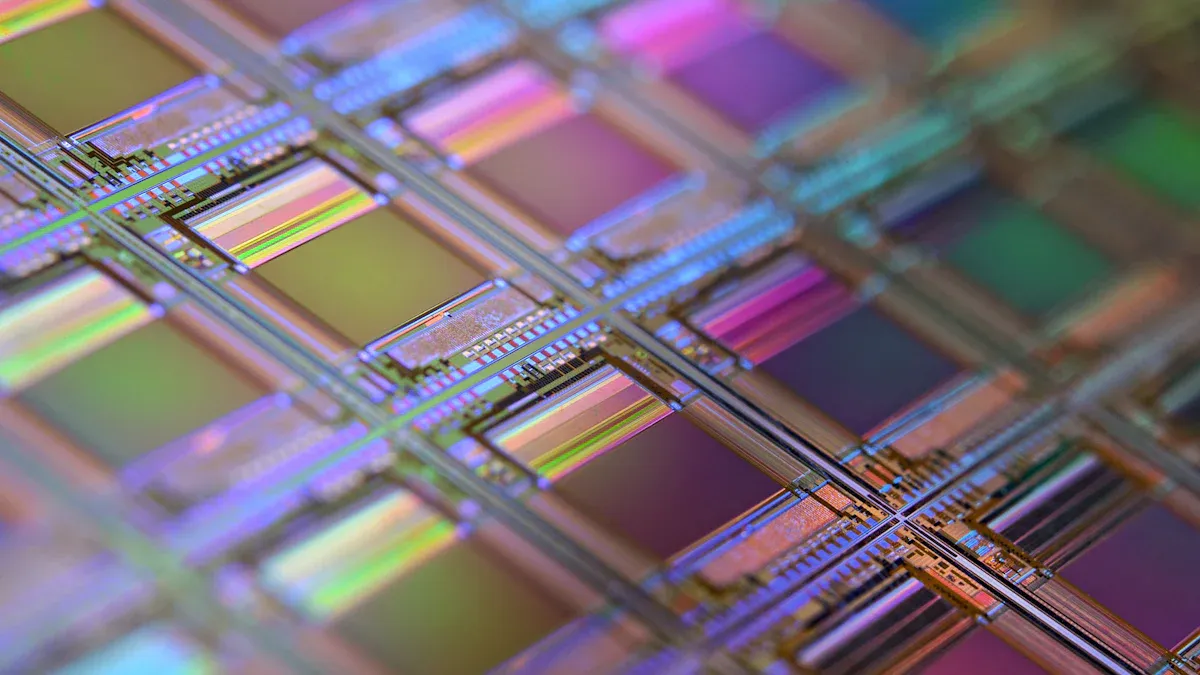

Manufacturers in 2025 use new methods to make SiC Cantilever Paddle products stronger and more reliable. They use advanced sintering techniques to create denser materials. These methods help reduce tiny holes inside the paddle. Fewer holes mean the paddle lasts longer and works better in tough environments. Some companies use 3D printing to shape paddles with more complex designs. This technology allows for faster production and less waste.

Note: New manufacturing tools help companies make paddles that meet strict industry standards.

Enhanced Purity and Customization Options

In 2025, companies focus on making paddles with higher purity. High-purity silicon carbide reduces the risk of contamination during use. This is important for industries that need clean and stable processes. Manufacturers also offer more customization options. Customers can choose the size, shape, and surface finish that fits their needs. This flexibility helps companies use SiC Cantilever Paddle solutions in many different machines.

| Feature | 2020 | 2025 |

|---|---|---|

| Purity Level | 98% | 99.9% |

| Custom Options | Limited | Extensive |

Adoption in Semiconductor and Solar Industries

The semiconductor and solar industries use more SiC Cantilever Paddle products in 2025. These industries need materials that can handle high heat and harsh chemicals. Silicon carbide paddles help keep production lines running smoothly. They also help improve product quality. Many factories now choose these paddles to meet strict safety and performance rules.

Tip: Choosing the right paddle can help companies avoid costly downtime.

- SiC Cantilever Paddle offers unmatched performance in high-temperature settings.

- Recent advancements in 2025 help this material lead the industry.

Many engineers choose SiC Cantilever Paddle for its reliability, strength, and long service life.

FAQ

What makes silicon carbide better than other materials for cantilever paddles?

Silicon carbide offers high strength, excellent heat resistance, and strong chemical protection. These features help it last longer than most other materials.

Can SiC Cantilever Paddle be used in cleanroom environments?

Yes. High-purity silicon carbide reduces contamination risk. Many factories use these paddles in cleanrooms for semiconductor and solar production.

How does silicon carbide handle sudden temperature changes?

Silicon carbide resists cracking from rapid heating or cooling. Its low thermal expansion keeps the paddle stable during quick temperature shifts.

Tip: Choosing SiC paddles helps prevent equipment failure in extreme conditions.